Researchers have been able to bioprint parts of the human heart

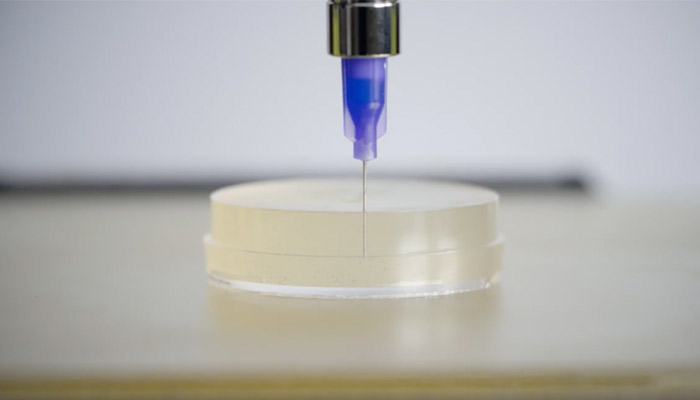

Scientists at Carnegie Mellon University are one step closer towards the manufacture of functional 3D printed organs: by using FluidForm technology, they have been able to reconstruct parts of the human heart, including heart valves. Called FRESH (Freeform Reversible Embedding of Suspended Hydrogels), this technology allows complex scaffolding to be 3D printed with unmodified collagen using a temporary support gel.

A few days ago, we reported on the research project of the ETH Zurich team, the team had 3D printed artificial heart valves from silicone. After two hours of printing, this valve was reinforced with collagen. American researchers went further this time by 3D printing directly from collagen, right from the start of the printing process. They even designed ventricles, valves and small blood vessels.

To achieve this medical breakthrough, the University team used FRESH bioprinting technology, a system that allows bioinks and other flexible materials – such as collagen – to be deposited layer by layer in a gel tank. This one acts as a printing medium as it allows to maintain the extruded materials, minimising the risk of deformation of the biomaterials. This gel is then heated to easily remove the bioprinted part, in this case a heart valve. CTO and co-founder of FluidForm, Adam Feinberg, explains: “We now have the opportunity to build concepts that incorporate the key structural, mechanical and biological properties of native fabrics. There are still many challenges to be met to bring us to 3D organs from bioengineering, but this work represents a major step forward.”

University researchers explain that they have performed several successful tests, including bioprinting small hearts based on MRI data. It seems they have succeeded in creating small ventricles from human cardiomyocytes, ventricles that contract synchronously. Of course, there are still many challenges ahead, including the generation of billions of cells needed to bioprint larger tissues – scaling up is a very delicate step. This bioprinting process must also be validated by regulatory clinical guidelines.

The teams of this project remain proud. Mike Graffeo, CEO of FluidForm concludes: “We are very pleased with the research carried out in Feinberg’s laboratory. The FRESH technique developed at Carnegie Mellon University allows bioprinting researchers to achieve unprecedented structure, resolution and fidelity, allowing for a significant leap forward in the field. We are delighted to make this technology available to researchers around the world.” You can find more information HERE.

What do you think of this research? Let us know in a comment below, or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!