Application of the Month: A New 3D Printing Material to Create Bone Grafts

As research into 3D printing materials progresses, more and more innovative projects are emerging in a multitude of sectors. This time, we want to highlight a medical application linked to additive manufacturing that was carried out by researchers at the University of Waterloo. The team has created an innovative material that mimics the properties of bone tissue and promises to revolutionize the treatment of patients undergoing reconstructive surgery and bone repair. The new material, a biopolymer nanocomposite, can be used in resin 3D printers to manufacture customized bone grafts tailored to the needs of individual patients.

Currently, major surgical reconstructions rely on metal implants and donated bone. However, these often don’t fit the patient’s anatomy perfectly, and can be rejected by the recipient’s body. This is why many medical centers and hospitals are turning to 3D printing. The capacity of 3D printing materials offers an alternative that could reduce the need for metal implants, lower the risk of infection and improve graft acceptance by the patient’s body.

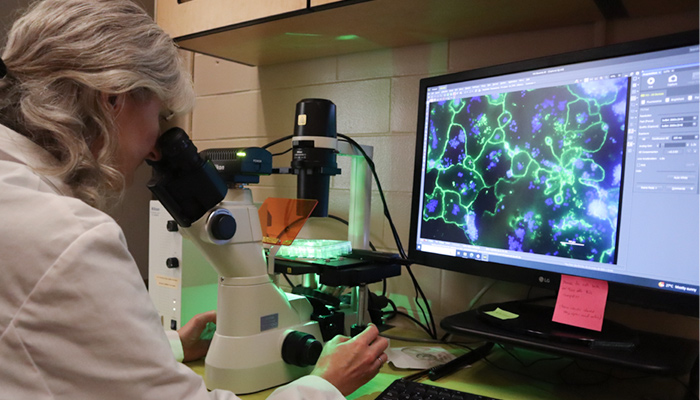

Dr. Maud Gorbet observes osteoclasts (cells that eat and resorb bone) in a 3D-printed nanocomposite material.

Improved Bone Grafts Thanks to 3D Printing

The material developed by the researchers incorporates nanoparticles that mimic the mineral composition of bone, reinforcing the biopolymer. The ultimate goal is for the patient’s own bone cells to grow and replace the nanocomposite with “new” bone, allowing the material to be eliminated naturally from the body.

Elizabeth Diederichs, PhD, Waterloo, explains: “Our work is currently focused on improving the functional strength of our biopolymer nanocomposite as an implant and its ability to be replaced by living bone over time. The aim is for this material to reduce the need for patients to undergo repeated operations after bone reconstruction surgery.”

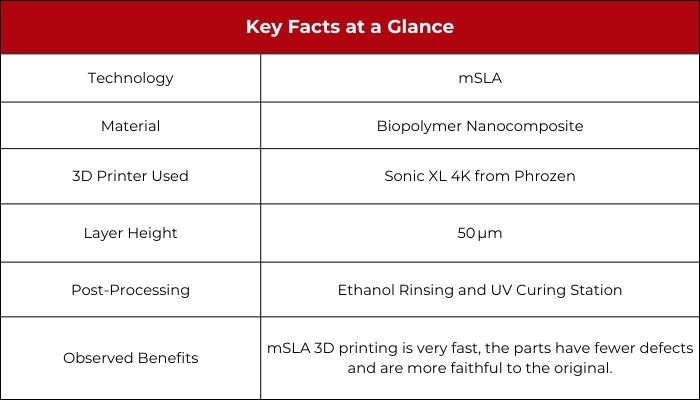

To achieve this, they used the Sonic XL 4K resin 3D printer from manufacturer Phrozen. Based on mSLA (Masked Stereolithography Apparatus) technology, this machine was used to create medical models with a layer height of 50 μm. Once the manufacturing process was complete, the biopolymer parts were rinsed with ethanol and post-treated in a UV polymerization station.

As for the technique used, the researchers tried extrusion printing, but did not achieve the desired results. They claim that, compared with other manufacturing processes, mSLA technology is much faster, enabling them to produce parts with far fewer defects and greater fidelity.

The research team, from left to right: Dr Dibakar Mondal, Elizabeth Diederichs, Dr Maud Gorbet and Dr Thomas Willett.

Initial compatibility tests with bone cells were successfully carried out in collaboration with Dr. Maud Gorbet, Professor of Engineering and Director of Waterloo’s Biomedical Engineering Program. “Any material implanted in the body elicits a reaction,” explains Maud Gorbet. “Our tests show that the biological response of bone cells to our biopolymer nanocomposite exceeds that of traditional methods. They adhere, proliferate and retain their behavior, which is very interesting.”

A Promising Future for This Biopolymer Nanocomposite

This breakthrough is part of the University of Waterloo’s Health Futures initiative, which aims to improve health and well-being through technological advances, virtual care and health data applications. With this new material, researchers continue to push the boundaries of medical technology and, in particular, the potential of 3D printing.

Lead researcher Dr Thomas Willett concludes: “We have created a solid, 3D printable material that is compatible with the potential to become new bone tissue. With this technology, we can achieve the patient-specific geometry needed to reconstruct bone defects more successfully.”

The team is now seeking funding to conduct further trials and obtain the regulatory approvals needed to bring the technology into the clinical setting. Below is a table with the most relevant information about this application. To find out more, click here.

Image Credits: 3Dnatives

What do you think of this new material for medical 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: University of Waterloo