Bioink Manufacturers: What’s on the Market?

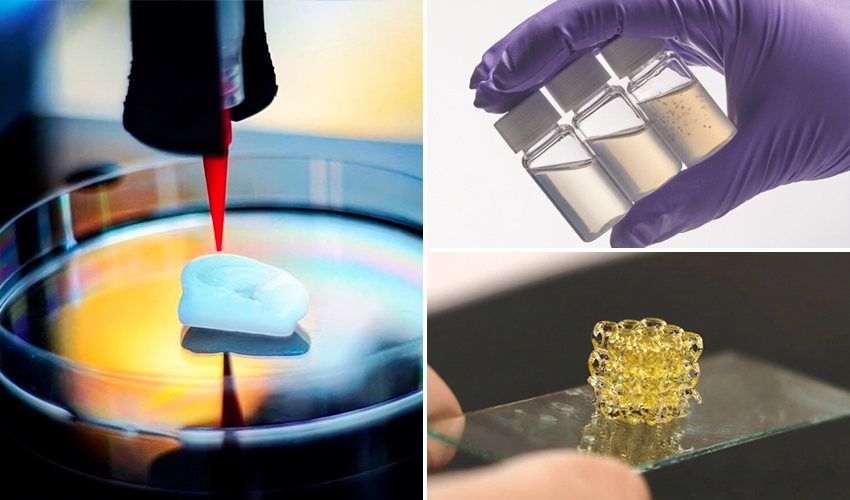

Bioprinting, which involves 3D printing living tissue models, holds incredible promise for medicine and biology. The technology helps researchers develop personalized medicine, engineer tissues and test drugs and cosmetics. Another application, while far-off, would be 3D printing functional human organs—a feat that could change the fate of thousands in need of transplants. Bioprinting can be achieved with various technologies and materials, and one of the most common is bioinks. These printable materials can incorporate live cells and bioactive molecules. While bioinks are made of diverse materials, they will typically help with cell adhesion, cell proliferation and cell differentiation during maturation. For an overview of bioinks on the market, we have made a list of companies that produce them, specifying the types of inks they make.

Advanced BioMatrix

San Diego-based Advanced BioMatrix specializes in 3D applications involving tissue culture, cell assay, bioprinting and cell proliferation. In addition to producing bioinks, Advanced BioMatrix has expertise in production, isolation, purification, cell culture, protein testing and other 3D matrix products, rendering the company an all-inclusive solution for bioprinting needs. It sells two different DLP printers, a Two-Photon Polymerization (2PP) printer and an extrusion bioprinter, along with over two dozen bioinks tailored to each technology. The lineup includes bioinks with collagen, hyaluronic acid, gelatin and to name a few. Furthermore, Advanced BioMatrix offers base inks for crafting custom bioinks specific to users’ needs.

A few of Advanced BioMatrix’s bioinks, including PhotoHA®-Soft (left), PEGDA-INK (center) and PhotoGel®-INK (right). (Image credit: Advanced BioMatrix)

Allevi

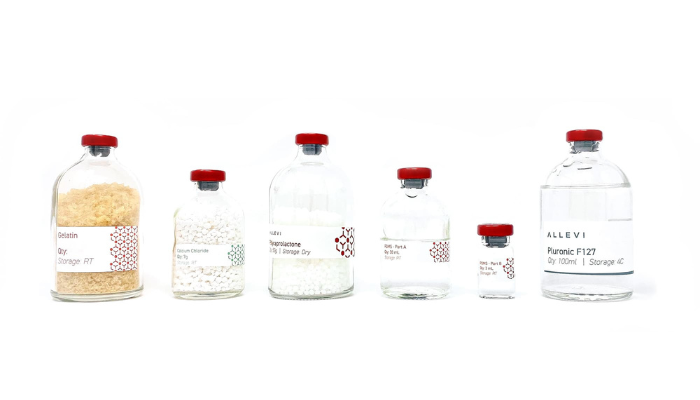

Allevi, a part of 3D Systems since 2021, is working to make it easy to design and engineer 3D tissues. To accomplish this, the manufacturer creates both bioprinters and bioinks that are used by researchers worldwide. Currently, they offer a wide range of bioinks, bioink additives, cells, reagents and consumables including for the liver, heart, bone, cartilage, kidney, nervous system, skin, vascularization, lung and brain. Allevi also asserts that all its bioinks have been thoroughly tested by academia and the tissue engineering industry for the best biological results. Common materials incorporated include collagen and hyaluronic acid.

Some of the materials available from Allevi (Photo credits: Allevi)

BIO INX

One of our most innovative 3D startups in 2023, BIO INX is a spin-off of Ghent University and Vrije Universiteit Brussel which focuses on the commercialization of materials and bioinks for 3D bioprinting. The company offers a number of ready-to-use bioinks including offerings for deposition-based 3D printing, multiphoton lithography, digital light processing/stereolithography and volumetric printing. You can even choose a bioink based on application, whether bone, cardiac, cartilage, ocular or organ-on-chip and biological function including no cell interactivity, cell encapsulation and cell seeding.

Photo credit: BIO INX

Cellbricks Therapeutics: Innovation with Implantable Tissue Therapies

Cellbricks Therapeutics develops implantable tissue therapies to improve the length and quality of patients’ lives. Drawing on its exclusive biomanufacturing platform and 10 years of expertise in tissue engineering, the company creates solutions that are biologically functional, immunocompatible and suitable for surgical implantation. These therapies represent a breakthrough in regenerative medicine by making cellular treatments implantable, guaranteeing stable grafts and effective treatment. Cellbricks combines therapeutic cells and customized biomaterials through light-based bioprinting to design these solutions.

Photo credit: Cellbricks

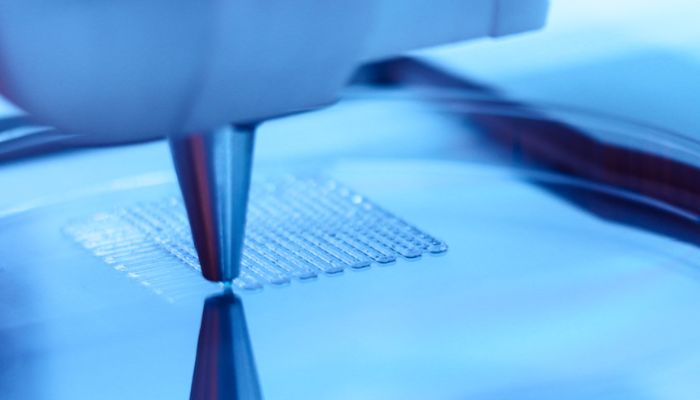

CELLINK

CELLINK, a leader in 3D bioprinting, offers advanced technologies for understanding and controlling biological processes. The company develops accessible 3D bioprinting solutions, providing researchers with the tools they need to transform the future of healthcare. In January 2016, CELLINK transformed the field with the launch of the first universal bioink. In addition to its bioinks, CELLINK also designs 3D bioprinters, such as the BIO X™, BIO X6™, INKREDIBLE+™, BIONOVA X, LUMEN X™, Quantum X bio and BIO ONE.

Photo credit: CELLINK

CollPlant’s Plant-Derived Collagen Bioinks

CollPlant is a regenerative and aesthetic medicine company that develops technologies and products for tissue regeneration and organ manufacturing. Its plant-based technology produces human-type I collagen (rhCollagen), identical to the collagen produced by the human body. The company has developed a line of bioinks called Collink.3D Human Collagen BioInk. These bioinks, made from plant-derived human collagen, are mass-produced with a high consistency, allowing them to perfectly mimic the native properties of tissues and organs. The collagen in these bioinks is extracted from genetically modified plants, ensuring compatibility with a wide variety of cells. In addition, CollPlant offers products for 3D bioprinting of tissues and organs, as well as for medical aesthetics applications.

Photo credit: CollPlant

Foldink’s Hydrogel Bioinks

Foldink, an expert in bioinks, bioprinters and other equipment and materials for biomedicine, has also developed inks designed to reproduce the structure and properties of the natural extracellular matrix, favoring tissue development. These bioinks are aimed primarily at research laboratories. Foldink has two types of bioinks, hydrogel bioinks and freeze-dried bioinks. Within the hydrogel bioinks, the company offers inks packaged in ready-to-use syringes, as well as specific bioinks for skin, bone, heart and liver tissues. On the other hand, freeze-dried bioinks are a cutting-edge solution, as they combine the advantages of GelMa and collagen, providing better results in tissue engineering, with greater thermal resistance and tissue cross-linking.

Photo credit: Foldink

Humanbiologics

Humanbiologics is a US-based company founded in 2018 that provides human-derived biomaterials for regenerative medicine therapies, 3D cell culture, disease modeling and 3D bioprinting. It is also the first company dedicated to providing a stable supply of affordable and high-quality human-derived biomaterials to researchers worldwide. In addition, Humanbiologics works with the American Association of Tissue Banks to store donated human tissue unsuitable for transplantation and provide the biomaterials. The products include human gelatin, collagen and extracellular matrices that can be used for translational research without having to rely on animal biomaterials. In addition, the products can be used independently or in combination with other biomaterials in a wide range of applications and areas of life sciences.

Photo credit: Humanbiologics

Innoregen

The Korean company Innoregen was founded in 2018 under the name Bioink Solution with the aim of becoming a leader in the fields of bioinks and tissue engineering through innovative technology and competitiveness. In 2020, the company released Col4Cell, a collagen-based bioink for 3D bioprinting with collagen hydrogel, which provides improved biocompatibility and structural safety and is used in regenerative medicine. Innoregen also supplies tissues with living cells that are tailored to numerous research projects in relevant areas. This means that the tissues are individually tailored to the respective research purpose, research field and research topic. The company also offers various bioinks, including Gel4Cell, Gel4Cell®-BMP, Gel4Cell®-VEGF, Gel4Cell®-TGF and Col4Cell, which can be used for applications such as osteogenesis, scaffold and many more, while providing an optimal environment for the development of living cells.

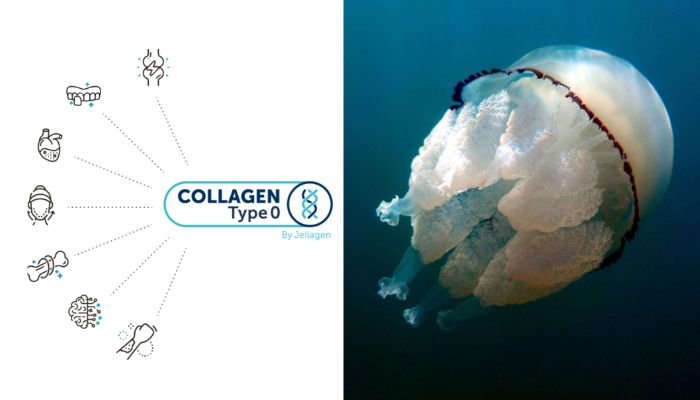

Jellagen and Collagen Type 0

The biotechnology company Jellagen has recently developed Collagen Type 0. This is an innovative material obtained from the extraction of proteins from the jellyfish Rhizostoma pulmo, fished from the waters of the United Kingdom and Europe. Unlike mammalian-origin collagen, not only is this material free of disease and prion risks, but it also solves the major ethical and health issues associated with using bovine or porcine proteins.

The biological properties of Collagen Type 0 make it particularly suitable for application in regenerative medicine. In vitro studies have shown that this material does not induce an inflammatory response and also promotes blood vessel and tissue regeneration. According to the manufacturer, Collagen Type 0 is ideal for applications in orthopedics, dentistry, and bone repair. This material is available in different versions: liquid, powder, film, sponge, hydrogel, and bioink.

Image credits: Jellagen

Solutions from ROKIT Healthcare

Seoul-based ROKIT Healthcare is a manufacturer of both 3D bioprinters and bioinks. Its INVIVO-GEL range is made from gelatin modified with methacryloyl groups. Its special feature is that it can be adjusted in terms of elasticity or rigidity, by modifying the concentration of gelatin and photoinitiators that harden the bioink. What’s more, the material’s formulation reproduces the extracellular environment. ROKIT Healthcare has also developed the HumanTein and EpiTem ranges, designed for research applications. Watch the video below to find out more about the bioprinting platform:

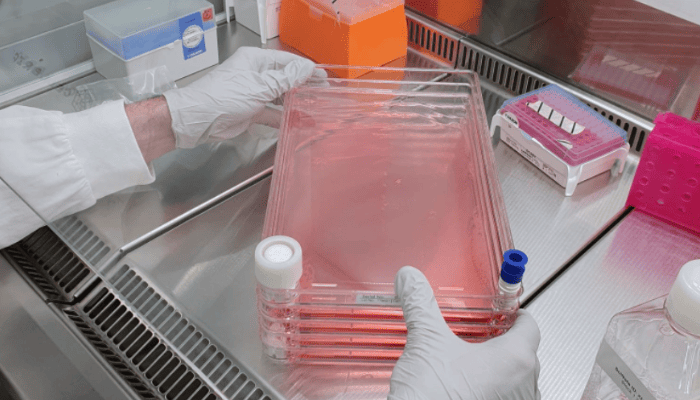

RoosterBio’s RoosterRTP™-hBM-50M-XF

The company RoosterBio has developed a vial of cells, called RoosterRTP™-hBM-50M-XF, intended for clinical applications and suitable for 3D printing. Each vial of RoosterRTP™-hBM-50M-XF contains 50 million mesenchymal stem cells (MSCs) ready to be extruded. RoosterBio uses MSCs because they have immunomodulatory properties and because they can differentiate into three different cell lines. Because of these characteristics, MSCs are widely used in therapeutics, with applications ranging from the treatment of brain injury to the management of graft versus host disease (GvHD) and cardiovascular disease.

The main problem is that millions of cells are needed to print a part such as, for example, a meniscus. An estimated 8.75 trillion cells per year are needed just to treat 20 percent of patients with damaged meniscus in the United States. To remedy this, RoosterBio provides ready-to-print vials with a high concentration of cells to drastically reduce preparation time and thus streamline the workflow for researchers and bioprinting companies.

3D model of a meniscus of an adult male with 3.5 cm in diameter and 5.3 mm in height. (Photo credit: RoosterBio)

Tessenderlo Group’s Gelatin-Based Bioinks

Tessenderlo Group is a Belgian company specializing in the fields of agriculture, mechanical engineering, bio-residue recycling and energy. At the heart of its strategy is a simple slogan: “Every molecule counts”. In 2019, the group presented its first range of bioprinting-compatible bioinks, Claro™. This includes the ClaroBGI600 solution, which is a gelatin suitable for printing for up to two hours. Indeed, the problem with such a material is that it generally clogs the machine’s extrusion mechanism. It must therefore be changed regularly. The group would have to overcome this challenge in order to offer greater printing precision and reliability. The bio-ink range is particularly suited to tissue engineering applications. We’ll let you discover the result on video!

GrowInk Hydrogels

GrowInk bioinks are biocompatible hydrogels patented by CELLINK and UPM-Kymmene Corporation. They are ready-to-use hydrogels of non-animal origin that can be mixed directly with cells for bioprinting applications. The two main components of GrowInk are nanofibrillar cellulose and water, which provide a fully defined matrix. The matrix can be customized by adding molecules, such as growth factors or adhesion proteins, according to the specific needs of the cells. In addition, they can be easily diluted to provide a wide range of stiffness and flexibility. GrowInks mimic the in vivo environment that supports cell growth and differentiation. This type of hydrogel combined with 3D bioprinting is particularly useful in research on cell development and function.

Photo credit: CELLINK and UPM-Kymmene Corporation

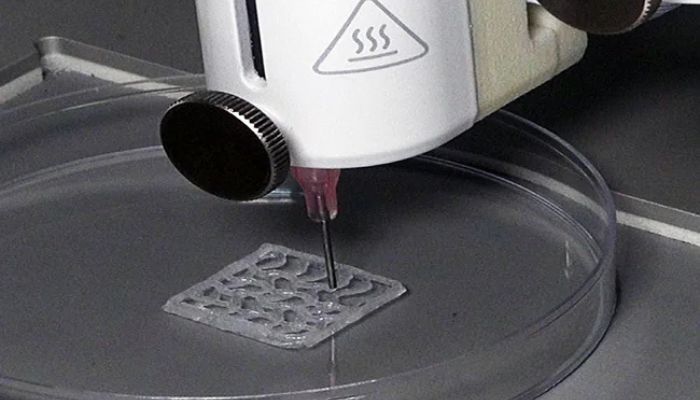

Fibrillar Collagen Bioinks for Printing Tissue Models

Fibercoll-Flex® fibrillar collagen bioinks are produced by Viscofan BioEngineering. They consist of pure type I collagen fibers with high mechanical strength and, according to the manufacturer, allow easy printing without a methacrylate curing step. Through bioprinting, it is possible to use these materials for research purposes, to create stable and highly biocompatible 3D models and to make structures for cell adhesion and remodeling. The company offers various types for different research applications. In general, structures made with Fibercoll-Flex and 3D bioprinting are applicable in tissue engineering or research and development in regenerative medicine.

Photo credit: Viscofan BioEngineering

Which bioink company interests you? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! For more on 3D printing medical applications, click here. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.