Interview with Biogelx about its bioinks and the future of bioprinting

Biogelx is a spin-out from the University of Strathclyde in Glasgow, engaged in the development and production of synthetic bioinks for 3D cell cultures and bioprinting applications. When we talk about this sector and its progress, we often talk about the creation of organs, but we must keep in mind that there remains much progress before we can reach this goal. This is one of the reasons why Biogelx is interested in short and medium-term bioprinting objectives and opportunities, which are just as important as 3D printing organs. The startup is therefore looking to develop its synthetic bioinks and is partly focusing on drug development, seeking to improve testing processes and reducing costs. We had the opportunity to speak with the Managing Director, Mitch Scanlan, to learn more about Biogelx’s ambitions and market vision.

3DN: Can you present yourself and your link with 3D printing?

Mitch Scalan

Born as a spin-out of the University of Strathclyde, Biogelx is pioneering the development of tunable synthetic materials for 3D cell culture and 3D bioprinting applications. In its early years, the company developed synthetic peptide hydrogels for 3D cell culture applications. The unique chemical and physical tunability of these scaffolds were quickly recognised on the market since they are capable of replicating the characteristics of specific tissues so that the cells experience and interact with a realistic 3D environment. Furthermore, these hydrogels do not suffer from the batch-to-batch variation experienced with natural hydrogels; thus, they provide a versatile and reproducible platform for 3D cell culture applications.

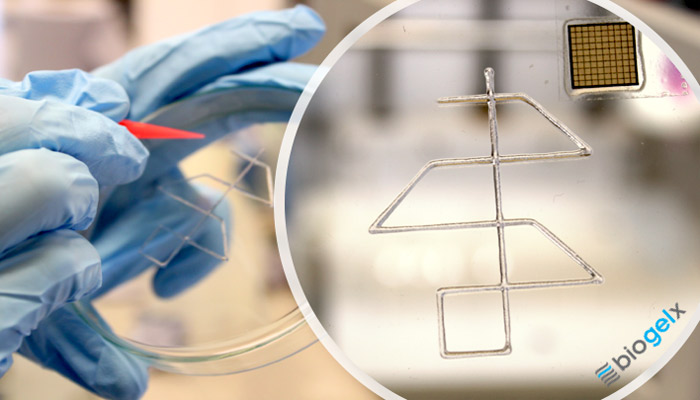

In parallel with the emergence of the 3D cell culture market, we have seen an additional market materialise for 3D bioprinting where there is a requirement for high throughput or increased precision. Since Biogelx has already established a range of products to support 3D cell culture, we decided to explore the potential of our core synthetic peptide hydrogel technology as a synthetic bioink for 3D bioprinting applications. Following an 18-month development programme funded by a SMART programme awarded by Scottish Enterprise we have designed a range of novel synthetic bioink which we are commercialising under a product family called Biogelx™-INK.

3DN: Can you tell us more about your new bio-ink product range? What makes it different?

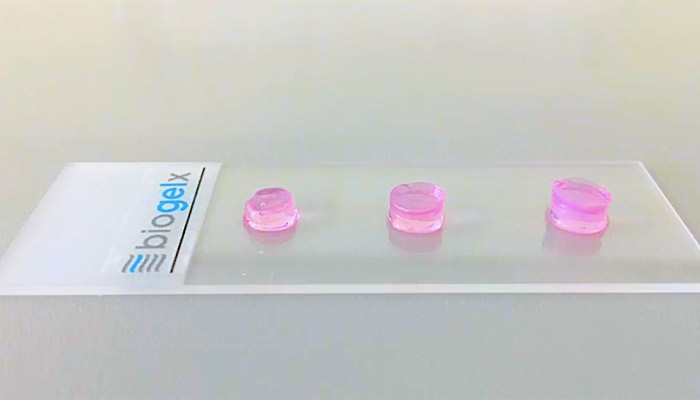

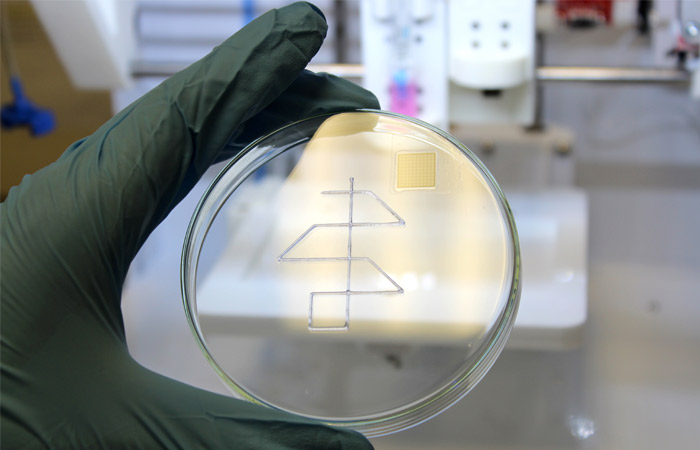

BiogelxTM-INK products are designed to provide versatility to support different printing applications. The key differentiator of these bioinks is the unique mix of their properties. They can be printed with excellent 3D fidelity and do not require the use of any support/sacrificial material. Furthermore, the Biogelx™-INKs print independently of temperature, pH, UV curing or addition of reactive crosslinking reagents. The addition of cell culture media containing physiological levels of calcium triggers the gelation; thus you have full control of the process. The Biogelx™-INKs are synthetic in nature which along with the strict quality control overseeing production, ensure batch-to-batch reproducibility, and in turn guarantees consistent bioprinting. With Biogelx™-INK technology we offer a convenient solution that addresses the challenges of printing and allows scientists to concentrate on their bioprinting research applications.

Photo credits: Biogelx

3DN: For what applications is it particularly suitable?

Biogelx™-INK products mechanical and chemical properties can be adapted, and they can provide excellent printability with cell viability. The product range includes a standard (Biogelx™-INK-S) and two functionalized with biomimetic sequences relevant for extracellular proteins such as fibronectin (RGD) and collagen (GFOGER).

Biogelx™-INK-S has been successfully tested with HepG2, A549, HCT116, HCT119, human bone marrow MSCs, MCF-7, and 3T3 Fibroblasts cell lines. Furthermore, we know that through a combination of chemical functionalisation and physical tunability, these products can be optimised to mimic a wide range of tissues and 3D cell culture applications. They have huge potential for screening in drug development and in the longer-term regenerative medicine and tissue engineering applications. Although we are primarily targeting research applications, in the future clinical applications will offer significant market growth opportunities.

3DN: Is your bio-ink compatible with all 3D bioprinters?

Biogelx™-INKs have initially been developed for use in extrusion-based printing techniques which represent >80% of the current 3D bioprinting market. However, thanks to the versatility of these materials where you are able to chemically and physically tune the base material to different applications, these materials can also be optimised for use in other printing technologies, and we are currently working with research groups evaluating the materials with other 3D bioprinting technologies like inkjet printing.

The Biogexl inks were developed in order to be extruded | Credits: Biogelx

3DN: What is the biggest challenge you faced when creating the bio-ink products?

During our market research, we identified that researchers were looking for new bioink biomaterials that could offer the biocompatibility of collagen aligned with the printability of commonly used materials such as alginate, plus the reproducibility and safety of non-animal derived, chemically defined, synthetic materials. Balancing these properties into our new synthetic bioinks has been our biggest challenge, however, we are fortunate that the materials are very versatile and through biochemical and mechanical modifications can be adapted to meet the challenges of a wide range of applications. We have been able to maintain the nanofibrous network of our hydrogel line of products in printable bio-ink formulations, to support cell growth in 3D bioprinted structures.

3DN: What are your future projects?

That is an exciting time for Biogelx. In addition to scale-up and commercialisation of our 3D cell culture and bioink products, we are actively looking to collaborate with academic and industrial partners to develop future applications as this exciting technology area continues to evolve at a rapid pace. We are expanding from our chemistry base to build cell biology expertise which will allow us to offer screening services for researchers to quickly identify optimal formulations for different cell applications. Adapting our materials to support next-generation printing and clinical applications means there will be no shortage of opportunities to drive future innovation and growth.

Photo credits: Biogelx

3DN: How do you see the future of bioprinting? How do you know the future of Biogelx on the bioprinting market?

We see massive potential in the bioprinting market and are keeping a keen eye on the industry’s future, but it’s important for Biogelx to focus on short to medium term applications within bioprinting that can drive commercial success.

There is a lot of interest from the media about printed transplantable human organs, however, this will undeniably take many years to achieve. Whilst we definitely want to be part of this journey we are also focused on more immediate opportunities for 3D bioprinting and bioinks such as the development of more accurate disease models and cell-based assays for the screening and testing new drugs.

There is a massive need in the pharma industry to develop better more physiologically relevant 3D models to test and screen drugs more effectively in early development. 3D bioprinting and synthetic bioinks can play a significant part to deliver this, leading to less animal testing, fewer drug failures and ultimately reduced the cost of drug development. If drug development organisations can identify ineffective or harmful drugs earlier in the discovery process and shift their resources to more promising drug candidates, this will have a massive impact by reducing the cost of drug development caused by late-stage clinical trial failures.

Photo credits: Biogelx

When it comes to drug development, and specifically for bioprinting applications, reproducibility and reliability are vital. At Biogelx we believe the future is synthetic, and that in order to balance printability with biocompatibility in the consistent manner required for such applications, chemically-defined bioink materials which incorporate biomimetic functionality are the best option.

You can find more information on their website HERE.

What do you think of Biogelx’s activities? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!