Engineers bio-print structures from sugar

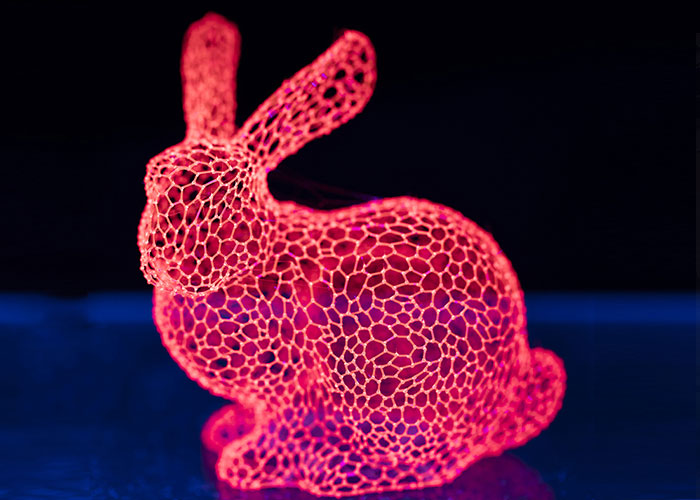

It appears that bioprinting is gaining more ground as engineers at the University of Illinois have reportedly developed a new sugar-based biomaterial that could have a significant impact on medical engineering and cancer research. The team of engineers has opted out of using a bio-ink or hydrogel, instead choosing to create a soluble and biodegradable material along with a new printing method that allows them to create intricately designed structures.

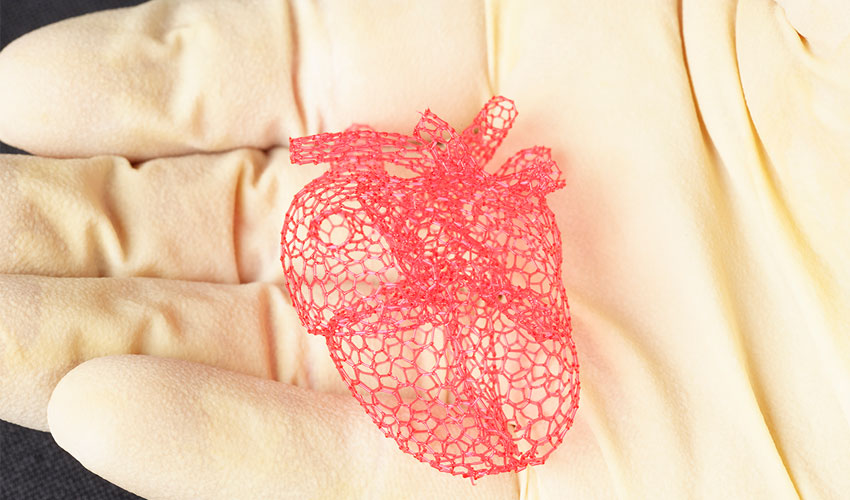

Bioprinting could be the future of customized medicine, thanks to the different methods that have allowed researchers to create tissues, cells, and more; all of which are fully adapted to the patient. There are different types of biomaterials today that take on many forms; The American engineers started with an isomalt-based material, an ingredient found in the sugar used in cough drops. It is water soluble and biodegradable, a key benefit in creating tissue supports for cell culture.

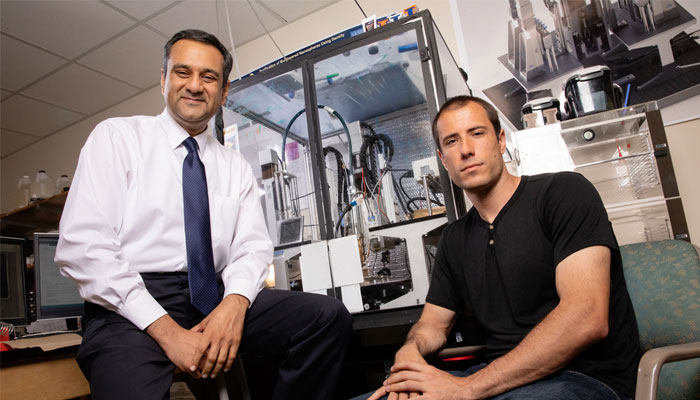

Professor Rohit Bhargava (left) and Matthew Gelber who developed the 3D printer (Photo credits: L. Brian Stauffer)

The team explains that they have also designed a very precise, free-form 3D printer to print complex structures. It works a little differently than a traditional 3D printer: instead of depositing the material layer-by-layer, the 3D printer prints isomalt ribbons and tubes that harden on contact with the air, much like a high-performance 3D pen. “This is a great way to create shapes around which we can pattern soft materials or grow cells and tissue, then the scaffold dissolves away,” says Rohit Bhargava, professor of bioengineering and director of the Cancer Center in Illinois. “For example, one possible application is to grow tissue or study tumors in the lab. Cell cultures are usually done on flat dishes. That gives us some characteristics of the cells, but it’s not a very dynamic way to look at how a system actually functions in the body. In the body, there are well-defined shapes, and shape and function are very closely related.”

3D printing with sugar is not really a first in the additive manufacturing market, but this time it seems that engineers have managed to overcome a number of challenges posed by this method. Combustion and crystallization are two of the major problems posed by 3D printing with sugar; the team would have had to maintain a temperature and sufficient pressure to circumvent this challenge. They also would have had to find the optimum nozzle diameter and the proper printing speed, allowing the material to be extruded evenly and harden into a stable form.

Isomalt structures offer a number of advantages for the field of bioengineering. Unlike 3D layer-by-layer printing, users can accurately control the mechanical properties of each part of the structure. Currently, this is the 3D printing technique used to produce tissue supports for a range of microfluidic devices and cell cultures.

Find more information on the University’s website or in the video below:

What do you think about this bio-based sugar material? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!