BIO INX Launches New, Ready-to-Print Bioink Resin for DLP 3D Printing

This week, the Belgian startup BIO INX launched a game-changing new material: BIORES INX, a gelatin-based bioink resin developed for digital light processing (DLP) 3D printing. Bioprinting with DLP has been limited because of the lack of biocompatible and biodegradable materials but resins like the BIORES INX are making that work a possibility. The ink is suitable for tissue regeneration and is compatible with cartilage, bone and cardiac applications.

What sets BIORES INX apart from other bioinks? Firstly, its gelatin methacrylamide (GelMA)-based composition closely mimics the natural extracellular matrix, enhancing biocompatibility. Gel-MA is derived from natural collagen, and according to BIO INX’s website, it is widely regarded as a gold standard in tissue engineering and biofabrication. Once the material is printed, it forms a strong, biocompatible, and biodegradable hydrogel network ideal for various biomedical applications including soft and hard tissue regeneration.

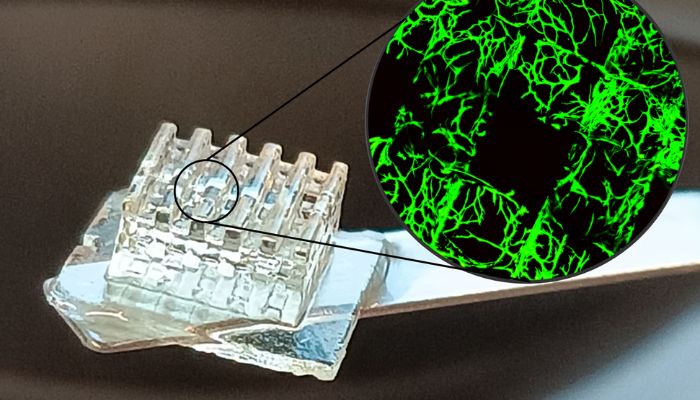

Microscopic view of a scaffold printed with BIORES INK

What’s more, the resin is ready to print and liquid at room temperature. This is significant because most gelatin-based resins are not liquid at room temperature and require heated containers. However, heating the resin can lead to water evaporation. By providing a gelatin-based resin that is ready at room temperature, BIO INX enables more straightforward processing. The BIORES INK is also ready to use because it is sterile and ISO 10993-3 certified. This certification means the resin demonstrates excellent biocompatibility.

Dr. Aysu Arslan, Chief Scientific Officer at BIO INX spoke on why the company created BIORES INX. “We believe that light-based bioprinting is the future of bioprinting thanks to elevated levels of reproducibility, higher resolution, and faster printing speeds. The combination of light-based printing technologies with the extreme biocompatibility of gelatin is ideal for biofabrication applications.”

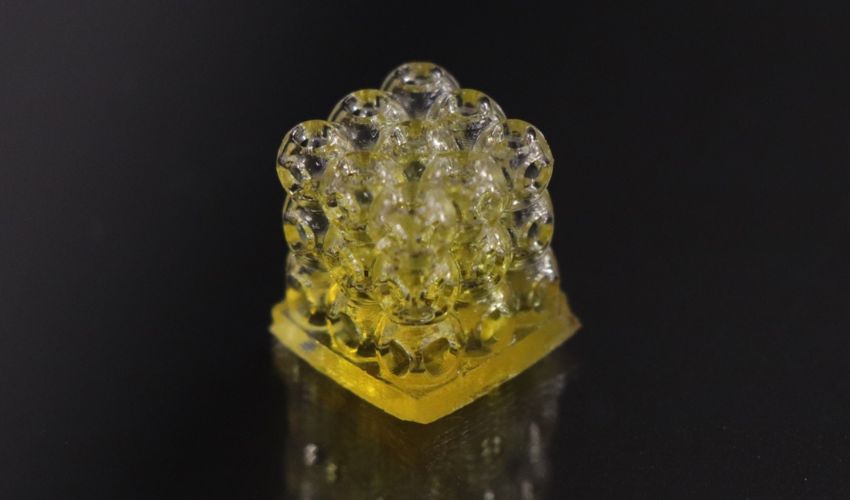

Printed blood vessel structure using the BIORES INK

BIO INX, which has established itself as a market leader in bioinks for high-resolution bioprinting, focuses on materials not only for light-based 3D printing but for extrusion 3D printing as well. “After introducing our HydroBIO INX portfolio for high-resolution printing and ReadyGel INX for volumetric printing, developing a gelatin-based DLP resin was the logical next step,” Dr. Arslan explained. “However, unlike volumetric and MPL printing, where gelatin’s gelation behavior at room temperature is advantageous, it posed a challenge for DLP printing—one we are thrilled to have overcome with this latest innovation.” To learn more, visit BIO INX’s website here.

What do you think of BIO INX’s new bioink resin? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: BIO INX