Bendable Concrete? UNM Engineers Develop Material for Construction 3D Printing

Concrete, construction 3D printing’s favorite material, is getting an upgrade thanks to research from the University of New Mexico (UNM). There, researchers patented a bendable concrete material design specifically formulated for 3D printing. This was not the only research project taking place in 2024 to optimize 3D printing concrete. In October, for instance, the University of Virginia made headlines for developing a 3D-printable concrete that reduced carbon emissions by 31 percent.

Concrete is strong and it handles compression well. But when it comes to tension, the material does not hold up. It is brittle, so it cracks and breaks easily. Even when reinforced with steel, it regularly requires ongoing repairs, whether used for buildings, bridges or sidewalks. A concrete with better tensile properties, like the one developed at UNM, could mean building stronger infrastructures that last longer and are less expensive to maintain. This could be especially meaningful in areas that are susceptible to natural disasters like earthquakes, which put lateral stress on buildings.

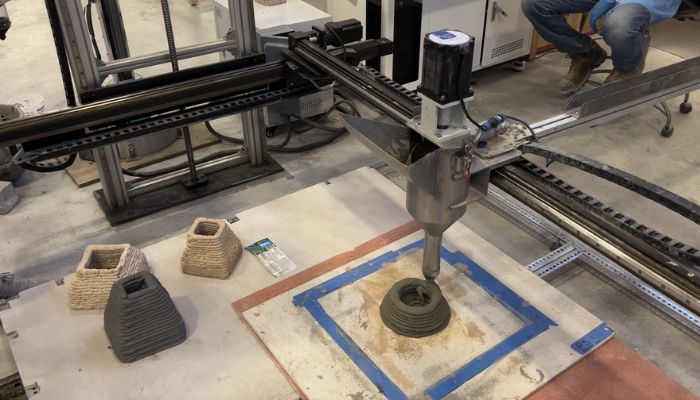

Samples of the bendable, 3D-printed concrete (Photo credit: UNM)

According to UNM’s release about the research, scientists worldwide have tried developing materials and processes that could resolve these issues. Some structures have been built partially with 3D printers, but so far, most processes require the placement of materials like beams or rebars, reducing the automation that 3D printing should offer. To print something without such support, the printing material has to be strong enough to support itself while being suitable for extrusion.

Maryam Hojati, assistant professor in the Gerald May Department of Civil, Construction and Environmental Engineering, aimed to find a solution. Her graduate research assistant, Muhammad Saeed Zafar explained their mission: “If we can successfully design ultrahigh ductile material without using conventional steel bars, [it] will solve the problem of the incompatibility of reinforcement with the 3D printing process.”

How Was the Concrete Mix Created?

The key here was fiber. Zafar created concrete mixtures with variable amounts of fiber, and to test their viability, he then precisely mixed, measured and printed them. The process was complex: too little fiber resulted in the prints collapsing, and too much fiber resulted in the mixture not passing through the printer easily.

Zafar printed many concrete designs, including small structures, prisms and dog bone shapes. Once printed, these designs were tested for bending and direct tensile strength. This process was then repeated, and the team made different mixes with materials like polyvinyl alcohol, fly ash, silica fume and ultra-high molecular weight polyethylene fibers.

The resulting substance, which they called a “self-reinforced ultra-ductile cementitious material,” was patented in August 2024 by UNM Rainforest Innovations on behalf of Hojati, Zafar and Amir Bakhshi, who worked as a research assistant early in the project’s development. In the patent, they list four different mixes with up to 11.9 percent higher strain capacity.

“Because of the incorporation of large quantities of short polymeric fibers in this material, it could hold all of the concrete together when subjected to any bending or tension load,” Hojati said. “If we use this material at a larger scale, we can minimize the requirement of external reinforcement to the printed concrete structure.”

The Transportation Consortium of South-Central States (Tran-SET) and Region Six’s University Transportation Center gave grants to fund the design of a bendable, printable concrete-like substance. UNM reported that the funding resulted in three research projects: “developing a 3D printable engineered cementitious material, evaluating the material’s properties in both fresh and hardened states, and developing a 3D printable eco-concrete.” Once the first two projects were complete, the researchers successfully designed the material and submitted it for a patent.

What Could Bendable Concrete Mean for Construction 3D Printing?

This self-reinforced ultra-ductile cementitious material would be optimal for 3D printing buildings and other infrastructure, offering greater resilience to natural disasters, less frequent maintenance and more construction automation. However, Hojati also has her sights set on space. Right now, she is involved in several projects that address space construction challenges, where construction 3D printing could play a part.

“This was very successful research,” Hojati said. “This material has 3D printing property and very high structural viability that could be used in the construction industry.” Learn more about the research in the video above, or read UNM’s article here.

What do you think of the bendable concrete for 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo: Screenshot from UNM video