3D Printing Bacteria: the New 3D Printing Material

Researchers at the Zurich Institute of Technology (ETH Zurich) have developed a bio-ink for 3D printing bacteria. This breakthrough could lead to the production of biomedical cellulose or biological materials capable of destroying toxic substances.

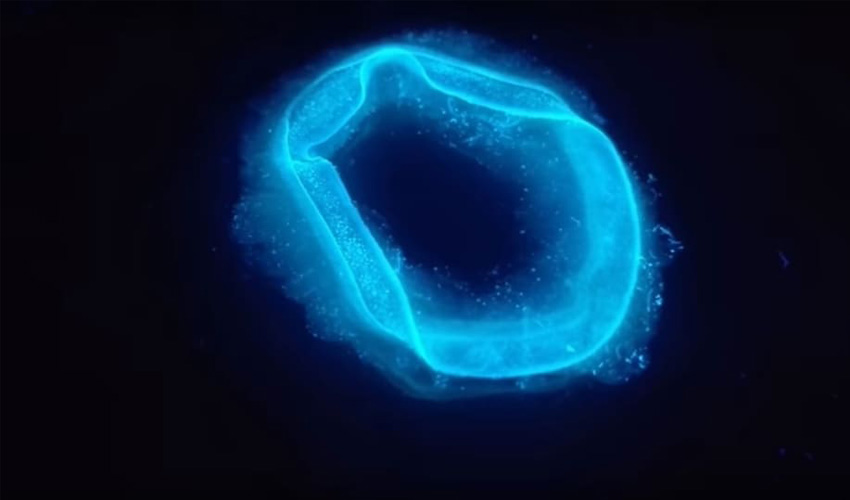

Researchers have developed a 3D printing platform able to print living bacteria to give 3D printed structures useful functional properties. This study is surprisingly similar to the research carried out by the Technological University of Delft, which 3D printed structures as solid as graphene from bacteria.

Complex bacteria structures.

Flink: 3D Printing Bacteria

‘Flink,’ or “functional living ink”, is the platform’s name. Researchers say Flink will offer significant opportunities in the biochemistry and biomedicine sectors. Researchers can create what they call microscopic plants from which they have previously selected the species of bacteria to print, affecting their physical properties. This opens the door for creating complex structures, such as artificial skin.

Researchers have so far tested printing with two bacteria: Pseudomonas putida and Acetobacter xylinum. Pseudomonas putida can destroy phenol, a toxic chemical, and Acetobacter xylinum which secretes nanocellulose that can soothe pain and maintain moisture. These are two useful properties for treating burns. The platform can print 4 inks at once composed of different bacteria. By precisely modifying the concentrations of each species of bacteria, structures can be printed with different physical and functional properties.

Bio-ink Composition

The 3D printable ink is composed of a biocompatible hydrogel and sugar, allowing it to be printed. However, one of the biggest challenges in the development of this platform was the creation of this hydrogel. It had to have good flow properties: not too liquid to form a solid shape but at the same time it had to go through the nozzle of the 3D printer. The researchers say “It had to be as viscous as toothpaste and with the consistency of a Nivea hand cream.” They also had to make sure the bacteria could move freely inside the hydrogel.

This solution that could be very useful for burn treatments, skin grafting and the creation of tissues. Find more information in the video below or on the ETH website.

What do you think of BQ’s 3D printing factory? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!