Augmented Reality Contact Lenses Developed Through 3D Printing

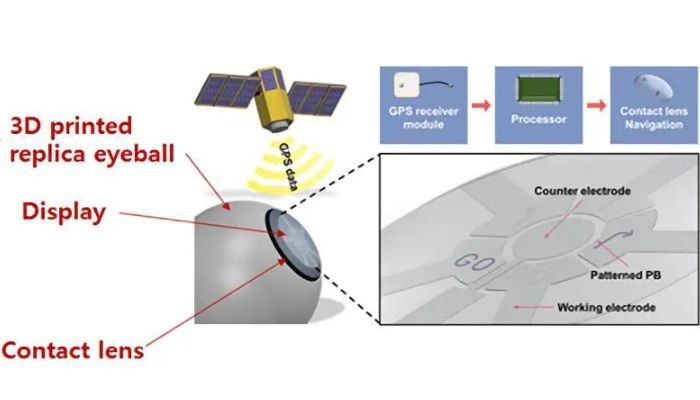

Intelligent contact lenses, like conventional lenses, can be placed on the eye and are able to provide the wearer with information. Currently, such lenses are mainly being researched in the medical field for disease diagnosis. Several companies, including Google, have already researched AR contact lenses, but there are still some technical hurdles to overcome. Now, researchers at the National Institute of Science and Technology (UNIST) in South Korea have teamed up with the Smart 3D Printing Research Team at the Korea Electrotechnology Research Institute (KERI) to develop contact lenses that enable augmented reality (AR) through 3D printing.

The technology involves printing micro-patterns onto a lens display. It uses the physical phenomenon of the meniscus, meaning the curvature of the surface of a liquid caused by surface tension: in this case the liquid is the printing ink. To manufacture the AR contact lenses, electrochromic monitors are supplied with low current. They make the lenses in the color “Pure Prussian Blue”, as the material ensures fast color contrast and color change, as well as being more cost efficient.

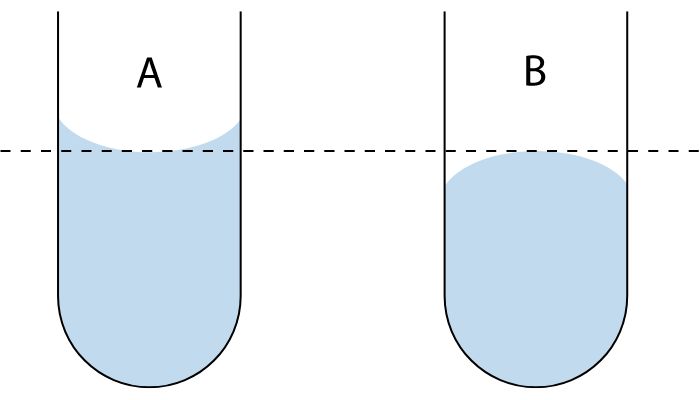

Menisci can be concave (left), as is the case for water-based fluids, or convex (left), as for mercury in glass. The researchers used the meniscus of the ink to print micropatterns (Photo credit: jleedev on Wikimedia Commons)

The most important application of AR contact lenses will probably be navigation. This means that the augmented reality technology is located directly on the eyes of the wearer of the lenses, navigating them through the streets. Moreover, in the future, users could play games like Pokémon Go not only on their smartphone or tablet, but directly with the AR contact lenses. Dr. Seol Seung-Kwon of KERI explained, “Our achievement is to develop a 3D printing technology that can print functional micro-patterns on a non-planar substrate to commercialize advanced smart contact lenses for AR.” He added, “It will greatly contribute to the miniaturization and versatility of AR devices.”

Chemical Reaction of the Process

Evaporation occurs between the micro-nozzle and the solvent, resulting in crystallization of the Pure Prussian Blue ink. As soon as the ink, which consists of iron(III) hydrocyanide, comes into contact with the substrate, the meniscus forms on the latter. When water evaporates from the meniscus, precursor ions and water molecules migrate to the surface of the meniscus. Subsequently, an accumulation of precursor ions occurs in the outer part of the meniscus, resulting in edge-enhanced crystallization of FeFe(CN)6. This process is of particular importance for controlling the crystallization factors of FeFe(CN)6 in the printing step to achieve uniform printing of the pattern on the substrate. Thanks to the use of the meniscus, the manufacturer can use any substrate. Moreover, the printing of the micropatterns is not limited to straight surfaces, because the researchers can also print on curved shapes.

Photo credits: SciTechDaily

The researchers believe the new technology will also be important for batteries and biosensors, as well as for the artificial intelligence sector. Read more about this AR contact lenses project HERE. What do you think of these 3D-printed AR contact lenses? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credit: StartupNoon