ASU-Haddy Collaboration Enhances Custom Furniture with AI-Powered 3D Printing

A collaborative effort between industrial engineers and forward-thinking furniture startups is poised to redefine the parameters of custom furniture manufacturing. Spearheaded by Feng Ju, an associate professor of industrial engineering at Arizona State University, and alongside industry frontrunners such as Haddy, Oak Ridge National Laboratory, and the University of Tennessee – Knoxville, the initiative seeks to leverage the capabilities of artificial intelligence to propel 3D printing processes to unprecedented levels of efficiency and innovation.

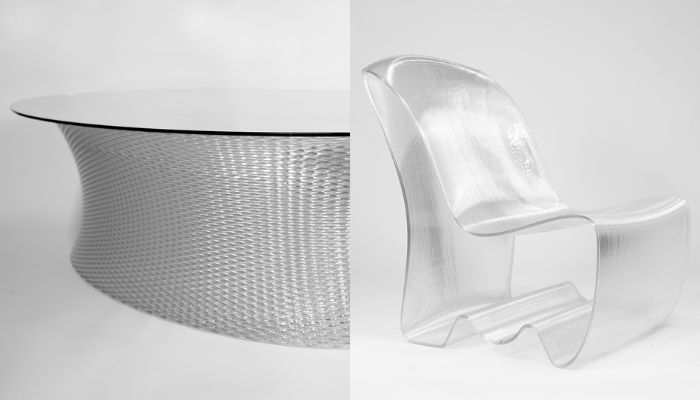

This initiative has set its focus on Large Format Additive Manufacturing, a cutting-edge technique capable of producing industrial-scale objects ranging from vehicles to furniture pieces. The engineering team perceives this technology as the key to producing furniture-scale objects with enhanced speed, creativity, and flexibility, with even more impressive benefits when coupled with AI.

LFAM requires a careful balance in printing speed. When 3D printing materials are extruded too rapidly, they may collapse, while printing them too slowly can result in debonding.

However, maintaining optimal printing temperatures is a fundamental challenge in large-format additive manufacturing. Haddy Senior Engineer Dylan Hoskins compared the challenges of this process to baking, detailing how engineers must carefully calibrate printing speeds to avoid material defects when stating, “You don’t want something to be underbaked because then it’s just going to turn to mush. You don’t want something to be overbaked because then it’s too hard. In both cases, the result is useless.”

Professor Feng Ju and his team are addressing this challenge head-on by developing AI algorithms that leverage thermal data and environmental cues to automatically adjust printing parameters in real-time. This is expected to result in significantly enhanced productivity, consistent quality, and an overall major leap forward in sustainable manufacturing practices. “The concept here is to help the machine make real-time decisions automatically for the printing process, speeding up when it can and slowing down when it has to,” Ju added.

Ju and his team have also begun exploring generative AI for furniture design. Drawing inspiration from platforms like ChatGPT, they are currently working on a digital assistant for designers capable of transforming plain language descriptions into intricate 3D models ready for printing. This development aims to democratize the design process while empowering designers to translate their visions into reality quickly and easily.

Recyclable furniture.

The project doesn’t just have significant benefits for productivity and creativity, but for enhanced sustainability as well. By integrating recycled materials into the furniture design and attaching NFC tags to each piece, Haddy is fostering a closed-loop system that ensures resources are efficiently repurposed to help minimize waste. Professor Ju and his team are scheduled to showcase their research this June at the upcoming Manufacturing Science and Engineering Conference in Knoxville, Tennessee.

What do you think of this initiative between ASU and Haddy? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Arizona State University