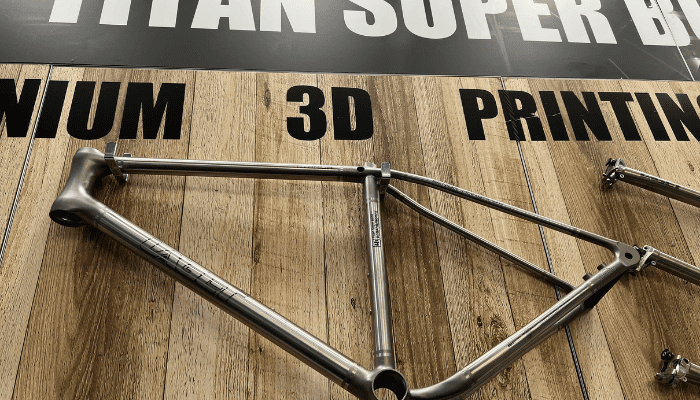

Asia’s Very First 3D Printed, Titanium Bike Frame Unveiled

3D printing has transformed several industrial fields, introducing improvements in the design and manufacture of objects. The bicycle industry is no exception, also taking advantage of this technology to push back the frontiers of conventional manufacturing. TITAN SUPER BOND, which specializes in the manufacture of titanium bicycle parts, has collaborated with BLT, a Chinese company specializing in metal 3D printing, to create the very first 3D printed, titanium bicycle frame not just in China but in Asia too.

China’s bicycle industry has faced certain challenges as of late. These namely center around supply chain issues starting around the start of COVID and affecting all of Asia. However, metal 3D printing is emerging as an ideal solution. Not only does this technology enable high-quality production, it also offers the possibility of manufacturing customized parts, thus improving bicycle performance and comfort.

A 3D Printed Titanium Bike Frame

IN 2022, TITAN SUPER BOND started using BLT’s BLT-A320 metal 3D printers. This cooperation has resulted in solutions designed to control the warping of complex parts and reduce their weight. The components produced not only passed the international ISO 4210 strength test, but also set new standards for lightweight design and manufacturing quality. The BLT-A320 3D printer has therefore been the key element in the creation of titanium bicycle parts, offering high precision, durability and corrosion resistance. Indeed, it is proving to be an ideal choice for a variety of materials, extending far beyond bicycle manufacturing.

This technology represents a real breakthrough in the reinforcement of certain areas of bicycles, where welds are subject to high stresses. In particular, this progress translates into a reduction in labor intensity and a considerable acceleration in overall production. Until now, bicycle manufacturing has been a complex process, involving a succession of stages typically lasting up to 45 days. The integration of 3D printing has radically simplified this process, not only reducing total production time by 30%, but also limiting material wastage by over 20%.

These improvements have a direct impact on the overall efficiency of bicycle manufacturing, creating a more sustainable and cost-effective environment. This drive to simplify and optimize the manufacturing process opens the door to a number of opportunities for bicycle manufacturers, particularly in China and Asia more widely.

What do you think of this TITAN SUPER BOND and BLT 3D printed, titanium bike frame? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.