All You Need to Know About ASA for 3D printing

ASA (Acrylonitrile Styrene Acrylate) is an amorphous thermoplastic similar to ABS: the main difference is that it is an acrylic elastomer, whereas ABS is a butadiene elastomer. It is found in filament form for FDM / FFF 3D printing. In this guide dedicated to ABS, we’ll focus on its production, properties and possible applications with this thermoplastic. The main manufacturers and pricing will round off our analysis.

Production and Characteristics of ASA

ASA was first marketed by chemist BASF in 1970 under the name Luran® S, and today can be molded, injected or extruded: ASA is increasingly used by people with FDM 3D printers. This thermoplastic is considered a “terpolymer”, meaning that the material is synthesized from three different monomers. It is obtained by polymerizing acrylonitrile, styrene and acrylate. In this case, styrene provides the gloss of the thermoplastic, while acrylonitrile provides chemical resistance, good moisture absorption and dimensional stability. As for acrylate, it enables ASA to withstand high impact.

ASA is suitable for making pieces with greater exposure (Photo credits: Stratasys)

Like ABS, it is manufactured from petroleum and is considered an engineering plastic, as it retains its appearance and impact resistance even under adverse conditions, such as prolonged exposure to air, rain, cold, heat, etc. For this reason, it is often used as an engineering plastic. For this reason, it is often used to manufacture everyday objects that need to be more resistant, such as electrical installations, car parts or even toys. Although ASA is made from petroleum, it can be recycled. What’s more, thermoplastic has a number of characteristics in 3D printing that distinguish it from the main plastics, which are PLA and ABS. Firstly, ABS is very prone to warping, and tends to discolor on contact with harsher environmental conditions. These two disadvantages do not occur with ASA plastic if certain recommendations are followed. It is also much more resistant to UV rays. What’s more, it’s a filament that’s easier to print than PLA and ABS, making it ideal for a number of applications, notably in the automotive industry.

ASA Characteristics for 3D Printing

As far as additive manufacturing is concerned, it has certain properties that must be taken into account for its use. For those who have experience 3D printing with ABS, this will be an easy task. However, if you do not have such training, you should follow a series of recommendations regarding the manufacture of parts with ASA. Firstly, it can be done with an open 3D printer, but it is recommended to use one with a closed chamber, as it can be sensitive to sudden temperature changes during the manufacturing process. In addition, this may reduce styrene emissions. Secondly, it is recommended to use tape (Kapton Tape) to reduce the possible warping effect during printing, in addition to providing thermal and electrical insulation.

ASA is very versatile, so if necessary, HIPS material could be integrated as an auxiliary support for models with cantilevers at less than 45º from the horizontal plane. It is also advisable to use a minimum layer fan. This will result in higher quality printed parts and avoid problems such as cracking or overheating of the 3D printer. Thus, the fan will help solidify the material without producing a sudden change in temperature. This thermoplastic melts between 245 and 260ºC, although each 3D filament manufacturer will have a slightly different range. It is convenient to put the printer bed at a temperature of 80 to 100ºC to avoid deformation.

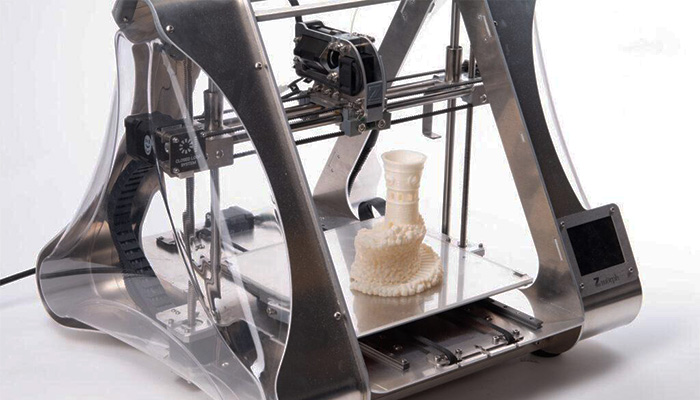

Photo Credits: ZMorph

The most important thing when 3D printing with ASA is to adjust the distance between the printing bed and the extruder properly. The correct setting will increase the adhesion to the surface, providing quality results. In addition to this, ASA has interesting features that should be highlighted. It has high dimensional stability (mechanical resistance), glass transition temperature and chemical resistance. All these characteristics make ASA easy to use and therefore suitable for making end-use machine parts or functional prototypes that will have a greater exposure to the outdoors.

Possible Applications with ASA

ASA offers a range of features that make it suitable for various applications. Its versatility allows it to be used for prototyping, tooling, and even end-use parts. The material’s exceptional resistance to weathering, UV rays, impact, and wear make it a reliable choice for producing components used in everyday items. From gutters, drains, and electrical panels to outdoor furniture, ASA can fulfill diverse needs. When reinforced with additives like fiberglass, it can even contribute to the construction of pedestrian bridges. The automotive industry also benefits from ASA, using it for designing car parts such as bumpers and side mirrors. Furthermore, the wide array of colors and finishes available in ASA make it ideal for creating visually appealing prototypes across various industries.

Photo credits: Kimya

Manufacturers and Material Price

BASF Forward AM offers a filament known as Luran® S, but they are not the only manufacturer to produce this thermoplastic material. Zortrax also provides ASA coils with a diameter of 1.75mm, priced at up to €40 for an 800g spool. Other companies like Stratasys, Kimya, FilamentOne, and Smart Materials also offer this advanced material to users. It’s worth mentioning that one significant difference between ASA and ABS is the price. While ASA is often touted as being “like ABS but better” in terms of quality, the cost of the filament reflects this improvement. For instance, a 1kg spool from FilamentOne is priced at €33, whereas ABS materials of the same weight range between €15 and €20, nearly half the price. To delve deeper into the specific characteristics of the filament, it is advisable to visit the respective manufacturers’ websites.

Have you ever printed with ASA? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!

*Cover photo credits: ZMorph

I don’t know if the color matters but for example one of top brand white color ASA I have prints a way worse than cheap black DevilDesign and this one prints even better than any PLA. However unfortunately none of then is hard like the PLA. It’s more like PETG than ABS I think.