Application of the Month: World’s First Single-Piece 3D Printed Inconel Rocket Engine

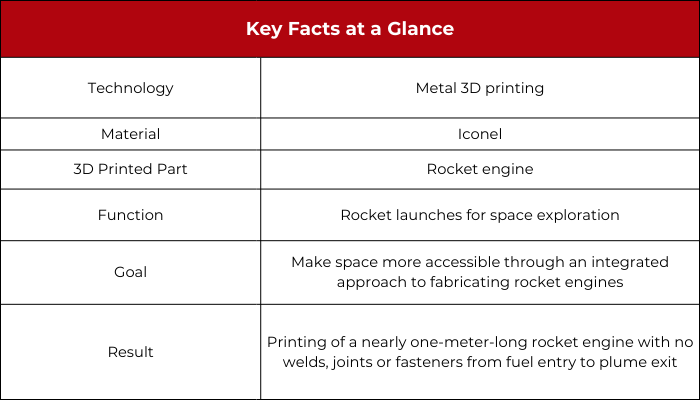

We’ve seen plenty of 3D printed rocket engines in recent years. In 2025 alone, New Frontier Aerospace successfully tested one, while POLARIS Spaceplanes trialed a 3D printed aerospike engine. Other major players, from Relativity Space to Launcher and Orbex, are also betting on additive manufacturing to unlock designs that conventional methods can’t achieve. Against this backdrop, what makes this month’s Application of the Month stand out? Enter Chennai-based AgniKul Cosmos, which has unveiled what is claimed to be the world’s largest single-piece 3D printed Inconel rocket engine. About a meter long, the engine is printed as one fully integrated component, without welds, joints or fasteners, from fuel entry to plume exit.

So why does it matter that the engine was fabricated in a single piece? For one, it greatly reduces manufacturing complexity, cutting out the time-intensive steps of welding, joining or fastening multiple components. It also minimizes the risk of weak points or failure during operation. AgniKul reports that its integrated approach reduced production time by more than 60% while also lowering the engine’s weight, resulting in a more efficient design overall. Beyond speed and scalability, the single-piece structure improves durability and fluid flow, marking a significant leap over the company’s previous generations of engines.

The evolution of AgniKul Cosmos’ 3D printed engines, highlighting how large their latest one is by comparison

The choice of material is equally critical. The engine is made of Inconel, a nickel-chromium-based superalloy prized for its strength and ability to withstand extreme heat and pressure. These qualities make it particularly well-suited for rocket propulsion, where components must survive the intense conditions of launch and flight.

Bringing Space Within Everyone’s Reach

AgniKul Cosmos was founded in 2017 with the mission of making space more accessible, and from the start, it has relied on 3D printing to advance that goal. The team has steadily built a portfolio of additively manufactured rocket components, beginning with its first fully 3D printed, single-piece upper-stage engine in 2019. Two years later came Agnilet, another single-piece design that went on to be tested at the Vikram Sarabhai Space Centre in 2022. Most recently, in May 2025, AgniKul made headlines once again by successfully firing India’s first electric motor–driven semi-cryogenic rocket engine, which integrated 3D printed pump subsystems.

Agnilet, a single piece, 3D printed, semi-cryogenic engine (left) and an example of a 3D printed rocket component (right)

Reflecting on the Inconel engine, AgniKul’s CEO and Co-founder, Srinath Ravichandran, emphasized its importance in a LinkedIn post: “This milestone marks a breakthrough in additive manufacturing at this scale & comes as a major extension of our earlier accomplishment of making & flying the world’s first single-piece engine. Compared to our earlier upper stage engines, these are longer, more complex and massive.”

The Significance of a US Patent

Adding to its list of achievements, AgniKul has also been granted a United States patent for the design and manufacturing process of its single-piece rocket engine. This provides the company with exclusive rights in one of the world’s most competitive space markets, a recognition of both its technical ingenuity and global potential. The Times of India noted that this is a rare honor for an India-origin design, underscoring the country’s growing influence in the aerospace sector. Ravichandran highlighted the moment, writing: “[It] means something to have a completely Indian origin design patented in the US – a nation that has built some of the most complex engines in this industry.”

The engine patent and design

AgniKul’s progress is being bolstered by strong partnerships. The company is working with institutions such as the Indian Space Research Organisation (ISRO) and INSPACe, while also receiving support from the Department of Science and Technology and the Technology Development Board. Together, these collaborations are paving the way for a new generation of rocket production, one where 3D printing doesn’t just simplify manufacturing but helps redefine what’s possible in space exploration.

To learn more about the AgniKul Cosmos, see its website HERE. What do you think of the AgniKul rocket engine? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. For more 3D printing news in the aerospace and defense sectors, check out our dedicated page HERE.

*Cover Photo: the single-piece AgniKul rocket engine (left) and a hot fire test conducted by AgniKul (right). All Photo Credits: AgniKul Cosmos