Application of the Month: A 3D-Printed E-Bike From Möve Mobility

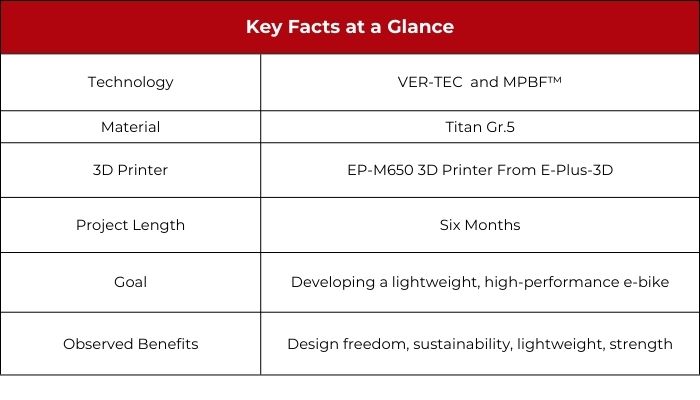

E-bikes have become a popular form of transportation in recent years, and even more powerful models are now being launched on the market, including those made with additive manufacturing. One interesting example of this is the Möve Avian e-bike, which was manufactured by Möve Mobility GmbH. In particular, the company caused a stir by combining 3D printing with its own patented VER-TEC technology and using it in the production of its e-bike model.

Avian is the world’s first ultra-lightweight titanium touring e-bike with an integrated battery, which was developed using 3D printing technology and in-house manufacturing processes. Parts of the frame, bottom bracket and titanium sleeves were 3D printed, which were then connected to hydroformed titanium tubes. It is the result of a partnership between Möve Mobility GmbH and E-Plus-3D, a specialist in metal 3D printing.

Möve GmbH, a company with over 100 years of history, has developed the Möve Avian, an e-bike that impresses with its ultra-lightweight design and manufacturing processes (photo credits Möve Mobility GmbH)

Breakthrough Due to the Combination of VER-TEC Technology and 3D Printing

But how exactly does the patented technology work? VER-TEC technology combines 3D-printed titanium sleeves and hydroformed titanium tubes to create a durable frame. The bottom bracket area is broken down into 133 gram sleeve segments, which are 3D printed and then connected to the high-quality tubes. This method ensures precise production, which makes the titanium frame not only functional but also suitable for series production. The new joining technique also replaces conventional welding processes and reduces production costs while optimizing the stability of the frame.

The frame, which is finished with VER-TEC technology, is also rustproof, which makes it particularly attractive for outdoor use and long-term use. Thanks to the use of titanium size 5 in its manufacture, it also remains light and robust. Overall, the complete frame weighs just 1.186g while the full bike weighs 11.8kg, which is an exceptionally low weight for an e-bike, setting it apart from others on the market.

The patented VER-TEC technology with 3D-printed titanium sleeves (photo credits: Möve Mobility GmbH)

The Use of Metal Powder Bed Fusion by Möve Mobility

Metal Powder Bed Fusion (MPBF) technology, or more precisely the MPBF™ technology from E-Plus-3D, is used for the 3D printing of the titanium sleeves and tubes. Thanks to the design freedom of 3D printing, it was also possible to fully integrate the battery into the frame. Tobias Spröte, Managing Director of Möve Mobility GmbH, confirms, “We chose MPBF™ because, at the state of the art, we could only achieve our production cost targets with the help of this process.” In addition, the entire production process was made efficient through the use of large-format 3D printing, enabling the project duration to be reduced to just six months.

However, the use of titanium in 3D printing also poses challenges, as the material requires support structures during the printing process, which in turn leads to intensive post-processing. However, E-Plus-3D was able to overcome these challenges by fine-tuning the printing parameters, which minimized material waste and the need for support material. Another technical challenge was the surface treatment of the titanium frame. Here, Möve Mobility GmbH used blasting to maintain a uniform matte finish that met both functional and aesthetic design objectives. This treatment improved the durability of the frame and provided an attractive appearance without compromising the strength of the material.

Overall, the use of VER-TEC technology in conjunction with metal powder bed fusion offers numerous advantages for the Möve Avian e-bike. These include, above all, light weight, which is achieved through the innovative production technology and titanium. Another important point that should not be overlooked is sustainability, as titanium is 100% recyclable, which of course has a positive impact on our environment.

What do you think of Avian and Möve Mobility GmbH? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Möve Mobility