Application of the Month: 3D Printed Titanium Tank from South Korean Consortium

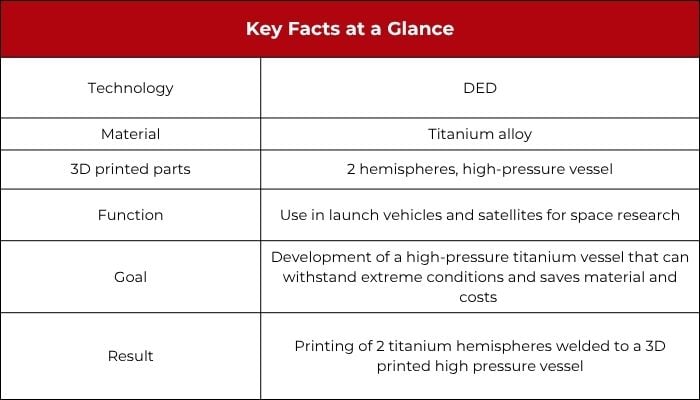

A group of South Korea’s leading companies and research institutions is driving a major breakthrough in space technology. The Korea Institute of Industrial Technology (KITECH), Korea Aerospace Research Institute (KARI), KP Aero Industries, AM Solutions, and Hanyang University have partnered on an ambitious project to advance additive manufacturing for the aerospace sector. Their goal is to produce high-pressure titanium tanks, which are essential components for launch vehicles and satellites, using additive manufacturing. The team recently reached a significant milestone by successfully manufacturing and demonstrating the reliability of a fully 3D printed titanium tank, setting the stage for future innovations in spaceflight hardware.

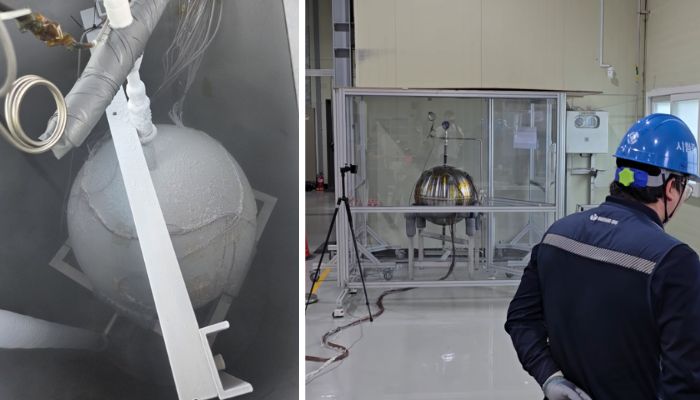

The goal of the project was to demonstrate the feasibility and resilience of a 3D printed space tank under realistic conditions. The resulting cryogenic tank, made of titanium, measures 640 mm in diameter and has a capacity of 130 liters. To test its performance under extreme conditions, the tank was deep-frozen and subjected to a cryogenic pressure test – with impressive results: the test was a complete success. The tank can withstand 330 bar of internal pressure at –196 °C, cooled by liquid nitrogen. This represents the world’s first successful test of a 3D printed high-pressure vessel under such extreme conditions.

The cryogenic pressure test (left) and a pressure test at room temperature (right)

DED and Two Hemispheres

KITECH assumed responsibility for the additive manufacturing process, using DED (Directed Energy Deposition) technology, which deposits titanium material layer by layer and simultaneously melts it. The production process involved two hemispherical titanium halves, which were welded together to form a monolithic tank after precise heat treatment and machining. Real-time monitoring enabled the precise implementation of optimized deposition paths – a key to the achieved geometric accuracy and mechanical integrity.

Additive manufacturing offers significant advantages over conventional processes, particularly for titanium. Traditional production methods suffer from material shortages for molds, design constraints, and high costs. 3D printing has overcome these limitations – with advantages such as greater material efficiency, design freedom, and significant cost savings.

The halves were manufactured using DED and finally welded together

The Importance of the Titanium Tank for Space Travel

High-pressure vessels are essential components in aerospace. They store liquid propellants and contain gases used for attitude and altitude control of spacecraft. Titanium alloys are particularly suitable due to their high strength, low weight, and stability at low temperatures – but have so far been difficult to manufacture. The project demonstrates that 3D-printed components meet these requirements.

Dr. Lee Hyup from KITECH KAMIC emphasizes: “This demonstration proves that large-scale additively manufactured structures can reliably withstand cryogenic and high-pressure conditions that simulate actual operating environments. It lays the foundation for widespread aerospace applications of 3D printing.”

Kim Hyun-joon from the Korea Aerospace Research Institute also sees a promising future: “We will continue our collaboration to conduct cyclic pressure tests at operating pressures and pursue further certifications for spaceflight capability.”

The research team

This project marks a significant milestone in the development of safe, efficient and future-oriented space systems – and demonstrates the great potential of 3D printing in the industrial production of critical components. More information can be found HERE.

What do you think of the 3D printed titanium tank? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. For more 3D printing news in the aerospace and defense sectors, check out our dedicated page HERE.

*All Photo Credits: KITECH