Application of the Month: The First 3D Printed Monolithic Catamaran

The maritime industry has undergone a major transformation in recent years thanks to the adoption of innovative technologies such as additive manufacturing. This production method enables ships and naval components to be created with unprecedented efficiency and sustainability. By reducing material waste, optimizing manufacturing times and enabling highly customized designs, 3D printing is positioning itself as a revolutionary solution in the marine industry. This is helped along by companies like Caracol, which is dedicated to developing large-scale additive manufacturing solutions. In collaboration with the V2 Group, it has developed the world’s first one-block, functional, 6-meter-long, 3D printed catamaran, designed to sail the high seas.

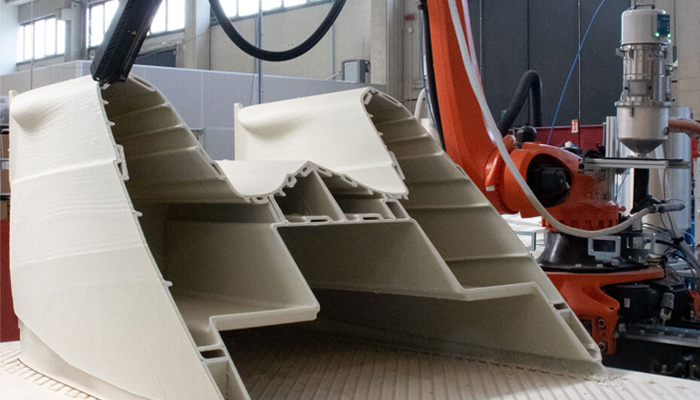

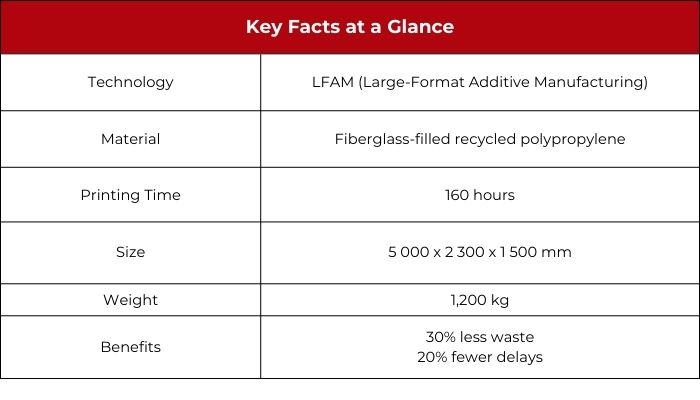

The innovative aspect of this project is that the boat was manufactured in a single print run, using the Heron AM LFAM (Large-Format Additive Manufacturing) robotic platform. This advance represents a milestone in the nautical industry, as it enables the industrialization and scalability of the large-format manufacturing process, optimizing every stage from design to post-processing.

Caracol’s LFAM technology, used for the monolithic catamaran

3D Printing a Monolithic Catamaran

In the maritime industry, large-format additive manufacturing offers competitive advantages such as design customization, efficient use of materials and reduced environmental impact. Caracol has implemented its complete Heron AM platform, designed to bring large-format additive manufacturing to industrial scale. This solution combines hardware, software and automation to deliver efficiency, flexibility and sustainability, optimizing the production of composite and thermoplastic parts. It is certified to high industry standards, guaranteeing manufacturing quality, continuity and control.

With Heron AM, the company has demonstrated that its 3D printing technology is not only viable in boat building, but can also replace traditional production methods. As such, the development of this catamaran was carried out with a long-term vision, with each stage of the process carefully evaluated. First, the print design and segmentation process required specific adjustments due to the catamaran’s size and geometry. However, these are made only once per model, allowing them to be reproduced in future productions.

The company used rPP GF material (recycled polypropylene with 30% glass fibers) to optimize printing times and guarantee the mechanical strength of the 3D printed catamaran. In addition, finishing techniques included CNC machining, gel coating and painting before extensive testing of the final hull. This last point is essential for the future industrialization of 3D printed boats.

The manufacturing process took 160 hours, reducing delivery time by 20%.

One of the main innovations of this project is the continuous 3D printing of the hull in a single 160-hour process, resulting in a monolithic structure without the need for additional assembly. Thanks to this method, the structural integrity of the vessel was improved and delivery times were reduced by 20%.

The manufacturing process involved the use of a high-flow (HF) extruder and an 8 mm nozzle. This optimized material deposition and ensured high print quality. In the end, waste was reduced by 30%, and the final weight of the monolithic catamaran was only 1,200 kg.

This project illustrates the potential of large-format additive manufacturing for the production of complex, high-performance marine structures. Furthermore, Caracol and the V2 Group will continue to refine this manufacturing method with the aim of extending its application in the marine sector. Industrialization of the process will enable more scalable, sustainable and accessible production, consolidating the technology as a viable solution for the manufacture of marine components.

Photo Credits: 3Dnatives

What do you think of this 3D printed catamaran? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel or find additional information about the automotive and transport sector HERE.

*All Photo Credits: Caracol / V2 Group