Apple To Use 3D Printing in Series 9 Apple Watches

Earlier this year, we reported on the rumor that Apple may be moving towards 3D printing its next series of Apple Watches. Ming-Chi Kuo, an analyst at TF International Securities and a reliable source for predicting Apple’s trends, said that the second-generation Apple Watch Ultra would incorporate some 3D printed titanium mechanical parts. The latest news of these developments comes to us from Bloomberg, according to whom Apple is currently testing the production of the new Apple Watch Series 9 with its case made of 3D printed metal. While the concept of 3D printing consumer goods is growing in size and interest, with the latest trends including toys, sandals and musical instruments, the potential impact of such change taking place at a tech giant like Apple merits attention.

The report detailed that the information obtained came from anonymous sources inside the company. The inside source goes on to clarify that Apple had already been testing 3D printing for several years and is now nearly ready for the market launch of the next-generation Apple Watch which will be produced with additive manufacturing. The company’s choice to switch to 3D printing gives voice to the fact that it is a more efficient manufacturing solution in terms of material amount used, waste reduction, sustainability, cost-effectiveness, as well as faster production speed than compared to standard CNC methods. Indeed, the shift may also herald a reorganization of their manufacturing structure, as 3D printing can give the company more control and flexibility throughout the production cycle.

The Apple Watch Series 9 (photo credits: Apple)

Binder Jetting Can Help Save Time, Money

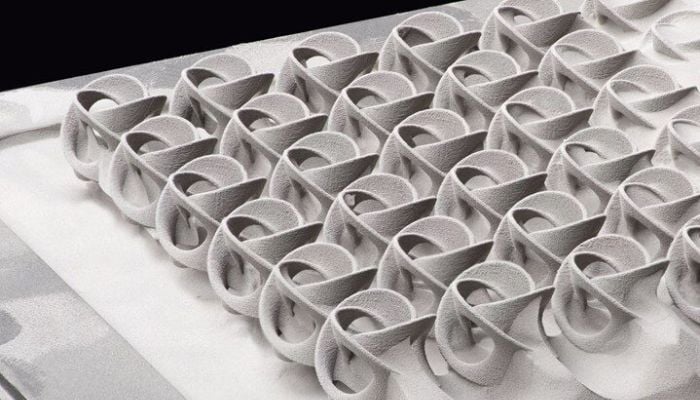

Apple has reportedly decided to use metal binder jetting, specifically with stainless steel. The process of binder jetting requires the placement of a thin layer of powdered material, after which a binding agent will be printed onto the powder layer by layer until the fused metal and binding agent form the desired shape. The traditional approach of making a watch case out of steel requires a block of metal, which is then machined into shape with a CNC machine. Switching to binder jetting could cut the raw material needs by a large margin and allow for a faster, more precise production process for the Cupertino-based company. After printing, the product would then be treated and smoothed into its recognizable shape to achieve an optimal final product.

According to the Bloomberg report, Apple will not be testing the AM process on the Apple Watch Ultra, as previously claimed, but the Apple Watch 9. The latter will most likely be unveiled this September when Apple’s announcements are usually made, such as for the launch of new iPhones. Interest surrounding Apple’s potential announcement is high, as launching 3D-printed watches on the market will mark a momentous step forward for additive technologies aimed at mass production.

What seems probable, given the timeframe, is that these tests around 3D printing production methods are bearing fruit and its success will lead Apple not only to launch next-generation watches produced using 3D printing, but also to gradually expand this process to more products in the coming years.

Binder jetting allows for dozens of objects to be made in the same print, making it a highly efficient production method. (photo credits: Markforged)

What do you think about Apple 3D printing watches? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Apple

Watches are increasingly upgraded to be more optimized and have more functions. I always believe that Apple will bring more experiences.