An Unusual Crystal Has Been Discovered That Strengthens 3D Printed Metal

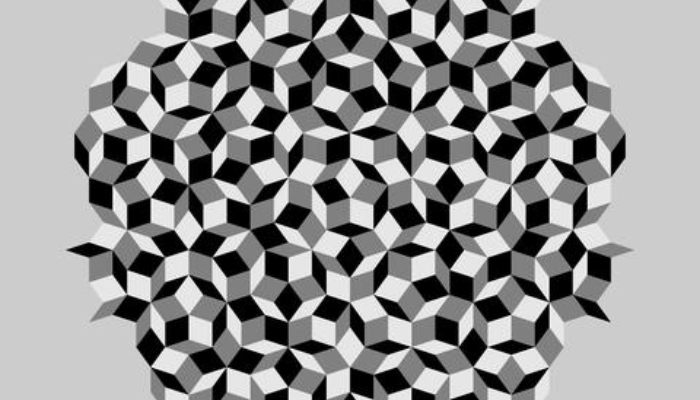

Metal 3D printing continues to advance, particularly in the reinforcement of parts for the aerospace and automotive industries. Recently, researchers highlighted a discovery in 3D-printed aluminum alloys: atomic structures called quasicrystals. These quasicrystals are unusual. Unlike conventional crystals, such as those in table salt, which have regular, repeating atomic patterns, quasicrystals adopt a different organization. Their structure fills the space, but never reproduces exactly the same pattern. This organized disorder could offer interesting mechanical properties, especially in additive manufacturing.

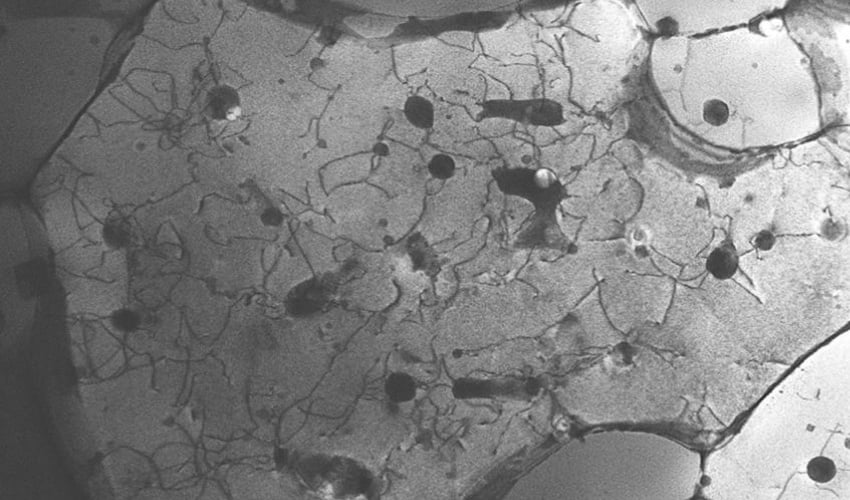

The discovery came about when researcher Andrew Iams was observing a sample of a new aluminum alloy and noticed an unusual organization of atoms. Working with other specialists at the National Institute of Standards and Technology (NIST), he was able to confirm that these were quasicrystals, rare structures that also appeared to enhance the alloy’s strength.

Penrose’s paving pattern is a good illustration of the behavior of quasicrystals. Though the geometric shapes are simple, their assembly creates a complex pattern that never repeats itself, even on a large scale.

Stronger Alloys Thanks to Quasicrystals

Thanks to this discovery, it should be possible to design new reinforced aluminum alloys, by making deliberate use of quasicrystals to enhance their performance. The NIST team not only identified these rare structures, but also demonstrated that they contribute to making the material stronger.

This is particularly important because aluminum is a difficult metal to master in 3D printing. According to Fan Zhang, a physicist at NIST, the strongest versions tend to crack as soon as you try to print them, making them unusable. Part of the problem is that, to be printed, aluminum has to be heated to extreme temperatures, well above its melting point, which alters its structure and properties.

In 2017, scientists developed a special alloy based on aluminum and zirconium, capable of being 3D printed without cracking. Intrigued by this breakthrough, NIST decided to analyze its structure at the atomic scale. As Fan Zhang explains, understanding how the atoms organize themselves is essential to guarantee the reliability of the material, especially if it is to be used in sensitive applications such as military aviation.

Their study revealed that quasicrystals play a key role in the alloy’s performance. In metals, too regular an organization of atoms can make them more brittle, as it facilitates the internal slippage that causes deformation. Quasicrystals, by breaking this regularity, create zones that block these movements and make the material more resistant. “Now that we have this finding, I think it will open up a new approach to alloy design,” said Zhang. You can find out more HERE.

What do you think of the use of quasicrystals to strengthen metals used in additive manufacturing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.