AMT on The Current Trends and Challenges of Post-Processing in 3D Printing

Thanks to recent technological advances in materials and production processes, the additive manufacturing industry continues to experience tremendous growth. In fact, according to some studies, 3D printing is generating greater acceptance and consolidation in a variety of application sectors. We have also seen that many companies are betting on developing new and innovative post-processing technologies, a phase of the process that is becoming increasingly important. One of them is Additive Manufacturing Technologies (AMT), a company founded in 2017 that specializes in post-treatment systems for 3D printed parts. Its main goal is to drive the adoption of this technology, not only to improve application performance, but also to scale up industrial production. To learn more about their patented technology and the vision they have for the current state of the additive manufacturing industry, we spoke with their founder and CEO, Joseph Crabtree.

3DN: Could you introduce yourself and tell us how you came up with the idea of creating AMT?

My name is Joseph Crabtree, and I am the CEO and founder of AMT. I am a material scientist by trade, which interestingly seems to be the trade of quite a few CEOs of 3D printing companies nowadays. Before AMT, I was involved in traditional manufacturing including injection molding, CNC machining, forging etc. When I started AMT in 2017, I was coming to 3D printing with the perspective of understanding traditional manufacturing and how this knowledge could be applied to it. We saw a good opportunity and I wanted to know how we could transform 3D printing into a viable manufacturing technology. I started to deep dive a little bit into it and realized that most companies were focused on the printer itself. Materials were starting to become more available in terms of choice and that was the focus in the industry. Then there was this recurring theme where everything after the printing process was not being discussed or addressed. To me and to our team, it seemed like an obvious opportunity to start a company and try to provide a solution for it.

My name is Joseph Crabtree, and I am the CEO and founder of AMT. I am a material scientist by trade, which interestingly seems to be the trade of quite a few CEOs of 3D printing companies nowadays. Before AMT, I was involved in traditional manufacturing including injection molding, CNC machining, forging etc. When I started AMT in 2017, I was coming to 3D printing with the perspective of understanding traditional manufacturing and how this knowledge could be applied to it. We saw a good opportunity and I wanted to know how we could transform 3D printing into a viable manufacturing technology. I started to deep dive a little bit into it and realized that most companies were focused on the printer itself. Materials were starting to become more available in terms of choice and that was the focus in the industry. Then there was this recurring theme where everything after the printing process was not being discussed or addressed. To me and to our team, it seemed like an obvious opportunity to start a company and try to provide a solution for it.

3DN: Which 3D printing methods and materials are compatible with your solutions?

We typically focus on thermoplastic polymers, specifically plastics designed for powder bed processes. This is really the technology that is being industrialized right now. When you look at who wants industrial amounts of manufacturing using AM, they are turning to powder bed fusion and thermoplastic polymers. Currently, polymers are our core focus, I do want to add however that we also have IP patents and intellectual property around metals and thermoset polymers. Maybe soon there will be some expansion into those additional opportunities as well. That said, our mission is to post-process every 3D-printed part.

3DN: Which type of users are you targeting with your vapor smoothing post-processing technology? What about depowdering?

We work with a wide range of customers across multiple industries, geographical locations and importantly sized companies: everyone from a small service bureau right up to very large multinational blue-chip companies. Our technology portfolio allows us to slot into any sort of requirements.

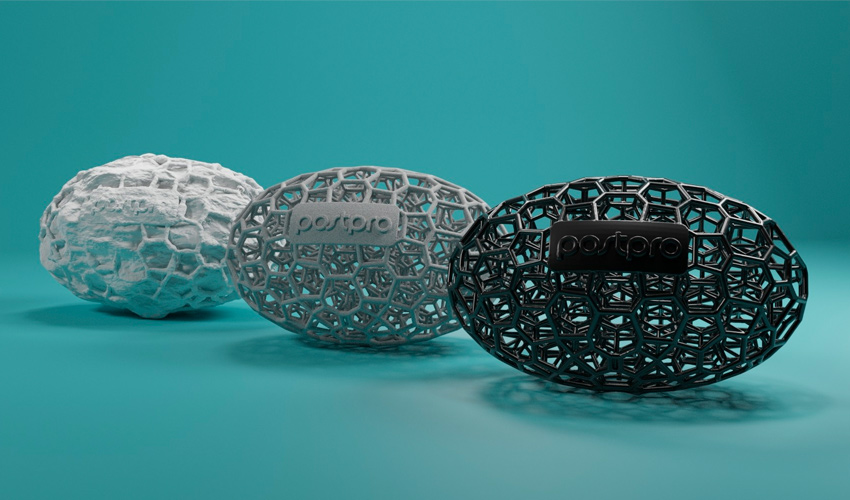

For depowdering, or cleaning, that is a necessary evil. Everyone needs to clean their parts, and that is the precursor to our core flagship process, which is the chemical vapor smoothing process – PostPro SF for Surface Finishing. We started off with the chemical vapor smoothing which transforms the part from a raw printed part into something that looks, feels and performs like an injection molded or traditionally manufactured part. Due to the success of that technology, we realized that even before the smoothing, cleaning needed to be done, but there were not really any solutions around. That is why we developed our own cleaning solutions. That being said, we expect our focus in the future to really be high volume additive manufacturing.

3DN: We are seeing a clear trend towards automation in AM. How is AMT working to address this issue in its processes?

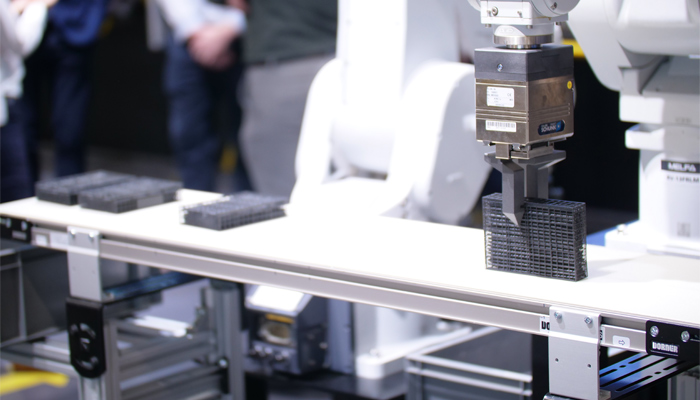

From day zero, we have always believed that the only way for 3D printing and additive manufacturing to become commercially viable is to remove all the people, to remove all the manual steps. And that does not just mean post processing. It means the materials, the printer and the post processing combined. To that end, we have created our Digital Manufacturing System (DMS), which is what we call our end-to-end workflow. And although we sell individual modules of our technology, really the goal is the full automation of that end-to-end workflow and we have realized that vision. Companies across the US, Europe and Asia are already using those today. And again, if you look at traditional manufacturing, it is not novel or innovative to automate a full end to end workflow. Take injection molding, forging or CNC machining, at scale they are all fully automated. And 3D printing is now playing a bit of catch up.

3DN: What are the remaining challenges in post-processing for 3D printing according to you?

One of the biggest challenges still is education. Five years ago, when we started, no one knew about post processing, it was an afterthought. But now, it has become a topic of debate and it is in people’s consciousness which is great. Though there are still people who are coming into 3D printing assuming it is as simple as just adding material to a printer, which obviously is not true. As such, there is definitely an element of education which is required in terms of helping the market and the general populace understand.

For what we are trying to do, there is the challenge of integrating the physical machines, the software, the materials or processes into a seamless system. In any other industry, it is very rare to go and buy five different products from different companies before trying to integrate them together. Adding to that, we require all the specifications to actually drive the correct adoption of the technology, including in specific end markets, like aerospace, medical, etc. Because in those sectors, there is already a significant amount of information on printing and material validation. But when it comes to post processing, it is just a black hole. For those reasons, we are very engaged with ASTM for example, to help be part of setting the standards so that we can have defined specifications for these processes as well.

3DN: Could you give us a sneak peek into AMT’s upcoming projects/releases?

As I mentioned earlier, from day zero, we have been working on this concept of an end-to-end automated system, our Digital Manufacturing System. But this year there are two big projects where we will be involved. First, with a company called Custom Color in the USA, who have developed a new consumer product making custom figurines at high volume. We will be developing and installing end to end process lines. We are talking about tens of industrial HP printers, and we are automating the entire workflow from the point of the printer all the way through to the part being packaged and ready for delivery to the customer. Those lines are going in. This is no longer hypothetical; we are actually doing it.

Then there is another big project which we are working on that is closely linked to automotive for a full end to end system from AMT in which includes all the unpacking and the cleaning of the parts including depowdering, chemical vapor smoothing, coloring, part, sorting, and inspection. And that will be delivered to our automotive customers again later on this year. It is incredible that in 2022, we will be exhibiting a fully automated end to end workflow from live printing all the way through part processing to the point where you collect your end parts. It will be the realization of six years’ worth of R&D.

3DN: Any last words for our readers?

I really think that for the next three years, the focus in 3D printing has to be on manufacturing. We have gone through various hype cycles. And I think if we can get to the point where 3D printing is not a novelty anymore, then we have succeeded. If we can get 3D printing to that level whereby it is combined to utilize as any other manufacturing technologies would be in the same types of factories, then we have really done our job. You can find out more about AMT HERE.

What do you think of AMT and its solutions for post-processing? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: AMT

It’s a very emerging trend in AM .. I am post graduate student and I want a dissertation in AM. PLZ Suggest something