AMGTA Study: Additive Manufacturing Reduces Emissions and Resource Consumption in Fashion Industry

Among the industries that are experimenting with additive manufacturing the most in recent years, the fashion industry is making important progress. However, freedom of design, shapes and materials is not the only reason for considering this production method. Sustainability and process efficiency are equally important when considering 3D printing as an alternative production method. This was confirmed by a recent study conducted by the Additive Manufacturer Green Trade Association (AMGTA).

The AMGTA has shared a detailed report demonstrating the environmental benefits of additive manufacturing in the fashion industry and specifically in footwear production. The study was conducted in collaboration with leading AM company Stratasys and Italian company Dyloan Bond Factory, which specializes in research and innovation in the fashion industry. The report clearly states that after a year of testing, the use of additive manufacturing reduced CO2 emissions and saved some stock material throughout the supply chain. Let’s take a look at some of the highlights of the study in more detail below.

Material Jetting vs. Traditional Luxury Goods Production

The AMGTA is an association committed to enhancing the sustainable aspect of Additive Manufacturing. Its activities include conducting studies that demonstrate through data the benefits of the technology. The recent report dedicated to the Fashion industry is titled “Comparative Analysis: 3D Material Jetting vs Traditional Methods for Designer Luxury Goods” and presents the results of a year-long collaboration between AMGTA, Stratasys, and Dyloan Bond Factory.

The use case focused on comparing traditional production methods (mainly injection molding) with PolyJet 3D printing technology (using the Stratasys J850™ Fashion TechStyle™ printer) to create 16,000 units of a logo to be applied to 8,000 pairs of luxury designer shoes. “This collaborative study with Stratasys and Pattern Group, assessing the impact of a print-to-textile process, is our first research undertaking involving polymer. It delivers important data that supports the value of AM to impact one of the most historically polluting industries in the world.”- commented Sherri Monroe, Executive Director of AMGTA.

3D printing and logo design application on a shoe.

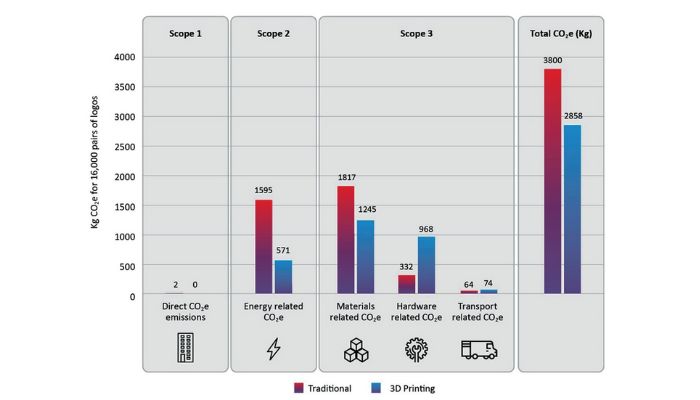

After a year of analysis, the results of the study are indeed promising and clearly establish that the additive manufacturing process using direct printing on fabric reduced CO2 emissions by 24.8 percent, compared to the methods traditionally used by the customer. Specifically in the case study, for 16,000 logos printed on 8,000 pairs of shoes, additive manufacturing reduced CO2 emissions by almost one metric ton. But that’s not all, the study points out that direct 3D printing on fabric saves 49.9 percent in stock throughout the supply chain, reducing and streamlining transportation activities. It is also a waterless process throughout the supply chain, potentially saving more than 300,000 liters of water.

If we look at power consumption, again 3D printing has brought significant benefits, reducing energy consumption by more than 64 percent. Finally, another noteworthy point is that 3D printing, by enabling the production of parts in a single process, allows in this case to reduce supply chain-related technologies from 4 to 1. This also optimizes production and logistical steps by reducing them from 12 to 2.

Global Warming Potential on the comparison between traditional manufacturing and 3D printing of 16,000 logo components.

Moving Towards More Sustainable Production in Fashion With 3D Printing

The result is indeed encouraging and certainly paves the way for more sustainable and green production in the fashion and luxury industry in general. “Producing sustainably is becoming increasingly crucial for designers in the world of luxury,” said Loreto Di Rienzo, Group R&D Director. “Stratasys’ innovation in 3D printing with the TechStyle™ technology enables us to offer revolutionary capabilities by reducing waste, minimizing reliance on natural resources and optimizing the environmental impact of our entire supply chain […] We can affirm and demonstrate that additive technology truly improves our environmental impact while expanding design freedom without compromising the quality of the end result.”

The study is part of Stratasys’ Mindful Manufacturing™ project through which the company is striving to rethink, together with its customers, the way things are made, redesigning processes, products and parts, but also optimizing operations for the benefit of people and the planet.

The Stratasys J850TM TechStyleTM 3D printer.

While it is true that this study focuses only on the life cycle analysis of the product logo and not of the footwear in its entirety, the results certainly imagine a new way of producing items, details, decorations, and accessories that are produced in large quantities in the Fashion industry and often require excessive use of resources, despite being small products. This study certainly shows that more sustainable and conscious production is possible. To learn more, the AMGTA’s full study is available: HERE.

What do you think of this AMGTA study on the fashion and luxury sectors? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photo credits: AMGTA/Stratasys