All You Need to Know About PVA for 3D Printing

PVA, or polyvinyl alcohol, is a material widely used in the 3D printing industry due to its ability to dissolve in water. In particular, it is used for the creation of print supports when using FDM dual extruder machines. This offers users greater design freedom for parts with complex geometries, without affecting print quality. The more details and cantilevered parts the design has, the more supports the part will require in order to be manufactured. This guide will help you better understand the properties of this material, as well as its role in 3D printing in obtaining the best results in each manufacturing process.

Production and Characteristics of PVA in 3D Printing

On a technical level, PVA is part of the synthetic polymer family, with the particularity that it is biodegradable. It is created by polymerizing vinyl acetate, which is then hydrolyzed to obtain the material in filament form for 3D printing. It has a transparent to off-white appearance and is highly resistant to oil and grease. In addition to having very good adhesive properties similar to other thermoplastics such as PLA, CPE or Nylon, this material has a high tensile strength and flexibility. It is also odorless, non-toxic and, as mentioned, biodegradable, making it safe for humans, animals and the environment.

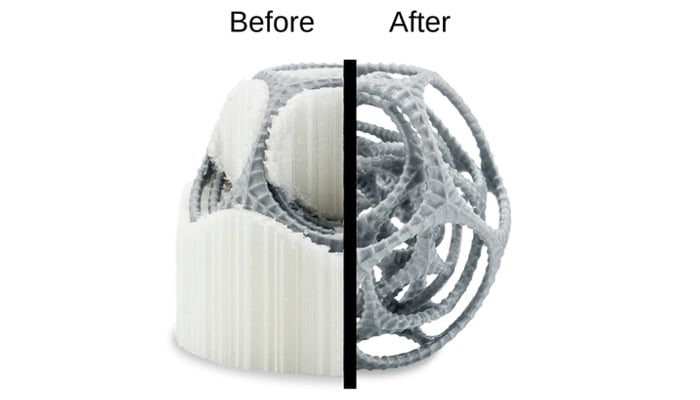

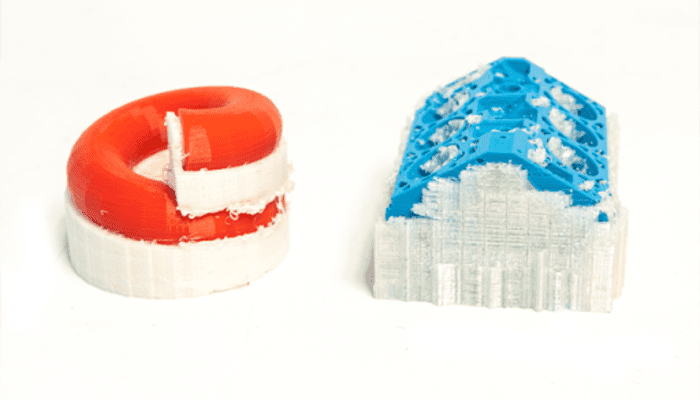

PVA is a soluble material used as printing support (photo credits: Ultimaker)

More specifically, it has a tensile elongation of 360% and a tensile strength of 22MPa. Depending on the humidity, PVA can also become very flexible and elastic, because water is like a plasticizer for PVA. PVA, which is actually brittle, fragile and tensile, becomes more and more elastic when moisture is added from the air or from water, and dissolves completely in water. Otherwise, it has a transparent to cream-colored appearance and is very resistant to oils and greases. It is easy to process in 3D printing because, among other things, it is non-toxic and actually odorless, although a slight odor may be produced during printing. However, for use in additive manufacturing, it is important to note the melting point of 230°C and especially the degeneration temperature of 200°C. At this temperature, PVA begins to carbonize, which can lead to black spots on the printed object.

3D Printing with PVA

Among its main advantages is, as mentioned, its ability to dissolve. Linked to this, the most remarkable thing is that it only needs water to remove the support material, i.e., it does not require solvents with more complex components. Furthermore, it does not require any additional hardware. However, it is also worth mentioning some of the disadvantages of PVA, though they are generally applicable to other soluble materials. One of these is the high sensitivity to moisture, which can directly affect the material. In order for its properties not to be altered, it will be necessary to keep it in areas where the air is highly controlled. PVA is also more likely to generate clogging if the nozzle is left hot when not extruding. To this can be added the fact that many users consider it to be an expensive filament for what it is, as it ultimately is not used in the final parts being printed, but rather dissolves in post-processing.

Furthermore, in order to obtain good substrate results, PVA requires preheating the printing tray to between 45 – 60ºC and bringing the extruder to a temperature of between 180 – 200ºC. Additionally, as mentioned, storage is critical. PVA filament should always be kept in a cool place and protected from light and dust. The optimum storage temperature is 15-25°C, away from sunlight. If the material has already absorbed moisture, it is necessary to dry it for about 8–12 hours at 50-80°C before printing with it. It is also better to print with materials with similar melting temperatures, such as PLA or PA.

Another important point to consider when working with this material is the configuration of the extruders. Cooling the PVA hotend while idle will prevent the oozing and clogging mentioned above. In addition, it is recommended to set the top support clearance distance to 0 layers for a more optimal surface finish. Since the supports will dissolve, it does not matter if they adhere to the final part during the fabrication process. The most pleasing results and smooth objects are achieved when the material is fresh and has been consistently stored dry. As soon as the PVA has absorbed too much moisture, this is already evident during printing by hissing noises and on the final object by curling, stringing, holes, bubbles and under-extrusion.

In post-processing, the PVA support structures simply dissolve in water (photo credits: MatterHackers)

In contrast to the storage of PVA, post-processing is extremely simple. Simply place the printed object in a water bath and wait 1-2 hours for the support material to dissolve. The water should be at bath temperature and can then be dumped down the drain, as PVA is biodegradable, as mentioned above.

Use and Applications

As a soluble material, PVA is ideal as a complement in the manufacture of parts with complex geometries, as well as internal cavities, conceptual models and molds. 3D printed supports offer improved surface quality and also allow the part to be oriented to optimize its mechanical properties. 3D-printed fixtures offer better surface quality and also allow the additively manufactured part to be aligned to optimize its mechanical properties.

Moreover, by allowing the 3D printing of all types of parts, no matter how complex the design, PVA is a material that is also widely used in the art world to create decorative models. However, it is not the only sector that is taking advantage of this filament. Even the most advanced industries that work with FDM technology to create tooling or prototypes are also increasingly integrating the soluble materials to create supports.

Manufacturer and Price

PVA filament is available on the market in standard thicknesses of 1.75 and 2.85 mm. When buying, make sure which thickness corresponds to the respective diameter of the hotend on your own durcker. As a rule, you can get filament spools of 500 grams of material at a price between $30 and $130 (though on average prices tends to be north of $50). However, prices vary depending on the manufacturer. Companies that offer PVA filaments include Ultimaker, eSun, Formfutura, XYZprinting, BCN3D, PrimaCreator, MatterHackers, Polymaker, Makerbot and many more.

Since PVA is by far more expensive than PLA, you can use a simple printing tip. Many slicers, such as Slic3r Prusa Edition, offer the option to print the part directly under the print object (“interface layer”) in PVA, but the rest of the support structure with the cheaper PLA. In this way, PVA and thus costs can be saved. If you want to learn more about other 3D printing filaments, you can consult our guide HERE.

What do you think of the characteristics of PVA in 3D printing? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Zortrax