Akira Science on 3D Printing Biomaterials for Tissue Regeneration

As 3D printing continues to revolutionize the healthcare field, more and more companies are exploring its applications in the development of innovative medical solutions. This technology, which excels in customization and precision, is transforming the way devices and materials are designed and produced for the healthcare sector. In the case of tissue engineering and regenerative medicine, 3D printing also offers enormous potential. This is the case of Akira Science, a Swedish company that is already taking advantage of this technology in its activity. Specifically, they have developed 3D printed bioabsorbable polymeric structures to facilitate tissue regeneration in various medical applications. We spoke with the Akira Science team to learn more about this solution and their use of additive manufacturing in medicine.

3DN: Could you introduce yourself and your connection with 3D printing?

My name is Álvaro Morales and I am the CEO of Akira Sciences. My fascination for 3D printing started in 2016, during the Materials Science module during my Chemical Engineering degree, taught by Professor Guillermo Vilariño at UPV. Professor Vilariño’s passion and inspiring methodology in tissue engineering ignited my interest in this technology, which led me to focus my career towards 3D printing and the development of advanced polymeric materials for biomedical applications.

That motivation later led me to pursue my master’s degree at the KTH Royal Institute of Technology in Sweden, I delved into the use of biodegradable polymers through the PrintKnit project, focused on the creation of 3D scaffolds for soft tissue regeneration. This experience not only solidified my vision on the integration of 3D printing into real clinical solutions, but also marked the birth of Akira Science.

On the left, Alvaro Morales, CEO of Akira Sciences

Once I finished my master’s degree I had the opportunity to do a summer internship in the same department where I was able to optimize the production process of scaffolds with medical grade materials, which led me to my first publication. After this year of learning, the big question came: PhD or working world? I decided to explore the industrial side of 3D printing, which took me to Germany, where I worked for two and a half years at EnvisionTEC, within the research and development department.

This stage was crucial and enriching, as it allowed me to acquire a comprehensive training and learn from colleagues from various disciplines, such as mechanical, electrical and software engineers. During this period, I focused on the development of DLP and cDLM technologies, collaborating on large projects with companies such as Henkel, BASF and Cartier. In addition, the COVID-19 pandemic presented us with the challenge of optimizing and obtaining FDA approval for swab printing, an enriching experience that also allowed me to delve deeper into the world of bioprinting with the Bioplotter team.

Despite these advances, I always felt the need to continue my research and lead my own long-term project. This opportunity came in October 2020, when my master supervisor, Prof. Anna Finne Wistrand, informed me about a PhD offer at the newly opened AM4Life Competence Centre in collaboration with the biopharmaceutical company Cytiva to develop 3D printing compatible materials intended for bioprocessing and post-processing development to improve the antibacterial properties of post-printing polypropylene SLS. Simultaneously, my passion for entrepreneurship and the possibility of further developing Akira Science motivated me to pursue my PhD and the development of Akira in parallel.

Now, as CEO of Akira Science, I apply this rich experience to develop biodegradable implants designed to regenerate tissue after oncological surgeries, such as breast reconstruction, marking a paradigm shift in reconstructive surgery through the use of our innovative 3D printing materials and techniques.

Akira Science is dedicated to the development of 3D printed tissues

3DN: What is Akira Science and how did the idea of creating the company come about?

Akira Science emerged as a spin-off within the Fibre and Polymer Technology Department at KTH Royal Institute of Technology under the development of the PrintKnit project led by Prof. Anna Finne-Wistrand. When I joined as a master student, the research group had an interdisciplinary group of organic chemists, biologists, computer scientists, and biomedical engineers, the perfect combination to be able to develop all the know-how from the synthesis of new biomaterials to the printing process and customization of the implant design. The interesting thing about this project is that it was born from a clinical urgency and evidence of the lack of new biomaterials in medicine.

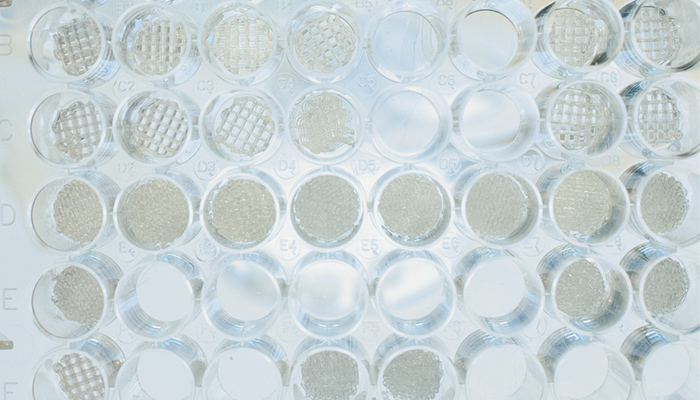

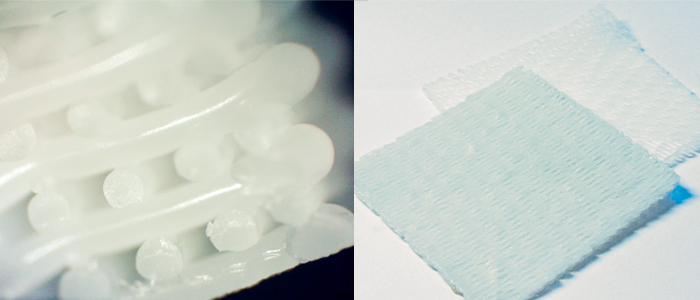

Unfortunately, surgeons have been using the same biodegradable materials for the last 30 years and there has been no innovation in the medical field. Therefore, our goal was to change this paradigmn and what we have developed is a library of a range of degradable polymers together with the printing technology and design of the implants to ensure the requirements needed to regenerate soft tissue: i) mechanical properties (stiffness) in the same order of magnitude as adipose tissue in the breast, ii) a material that is stable to high temperature processing and sterilization technique and iii) a material that degrades at the same rate as the tissue regenerates allowing the proliferation and expansion of stem cells and their specialization into adipocytes within 9 to 12 months. And that is what we did.

At the end of the project and after verifying these results at the preclinical level, the university’s transfer center, KTH Innovation helped us design a strategy for the intellectual properties and it was where we drafted our first patent. Personally, my motivation and my dream since I was little was to have my own company and although I started as a simple student, I ended up acquiring the majority of the shares of the company. In fact, I participated in all of KTH Innovation’s entrepreneurship programs to the point of being accepted into the prestigious DeepTech Incubate at STING, awarded as the best start-up incubation program in the world.

The reality was that most of my colleagues did not have the motivation for product development and decided to continue their careers within the scientific field or in companies of a higher caliber. My desire and passion and above all my belief in the science that has been done has led me to continue with Akira Science and I will not stop until I see our implants in every hospital.

3DN: What is your method to 3D print tissue and what benefits have you observed with this technology?

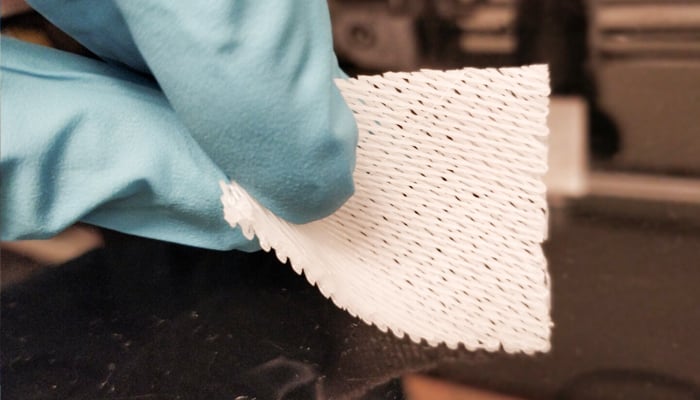

Our proposal is to use an acellular scaffold, i.e. we do not use any growth factor or any type of stem cell in our implants. The first requirement imposed by the clinical side was to have a material as inert as possible to avoid any kind of rejection (or allowing the cancer to reproduce again) and to act as a support for the cells already present in the breast to adhere, reproduce and promote tissue regeneration. Our printing method is based on filament printing where we have to work under specific conditions.

For this, I had to optimize both the extrusion and the printing process in order to meet the requirements imposed by the implant design. In turn, our implant is based on an interconnected mesh with a high degree of porosity that allows the diffusion of cells and enables homogeneous tissue growth. The combination of our biomaterial, printing process and implant design makes Akira Science a unique company in the industry with incredible potential for other applications in the field of soft tissue regeneration.

The benefits we have seen is that our platform can help both researchers and healthcare professionals in advancing and implementing a paradigm shift. Not only do we help patients, but we simplify breast reconstruction surgeries by saving 30% in operating time and saving hospitals up to 50% in resources. Consider that the waiting time in Europe to receive a reconstruction surgery is around two years long, this is due to the complexity of the surgery and the need to include plastic surgeons and general surgeons (oncologists) to plan the treatment. With AkiMed implants none of this is necessary, it is simply to open and place the implant after removal of the tumor.

3DN: Can you tell us more about your AkiMed™ breast implants? How many women have benefited from these advances?

So far, AkiMed™ is in the preclinical phase, which means that our implants are being tested and validated in animal models before being used in humans. Although implants have not yet been performed in women, preclinical results are promising, showing excellent biocompatibility and efficacy in adipose tissue regeneration.

Our vision is that once the clinical phases are completed and the necessary regulatory approval is obtained, the AkiMed™ implants will offer a revolutionary new option for thousands of women undergoing breast-conserving surgery after cancer. These implants will not only simplify the surgical procedure by reducing the number of operations required, but will also significantly improve recovery times and cosmetic outcomes for patients.

Thanks to 3D technology, they are able to reduce operating time and resources.

3DN: In your opinion, is 3D printing the tool of the future in medicine?

3D printing is definitely transforming the future of medicine. Its ability to create customized solutions, from implants to prosthetics to bioprinted tissues, is revolutionizing the treatment of many diseases.

For Akira Science, we have focused on developing biodegradable implants that facilitate soft tissue regeneration in a natural way. This technology not only reduces surgical time and hospital cost, but also improves clinical outcomes for patients. As we advance biocompatibility and the integration of 3D printing with advanced biomaterials, we see tremendous potential for its application in reconstructive surgeries, organ regeneration and personalized medicine.

I would like to add that I have been fortunate to be able to see first-hand how 3D printing is getting closer and closer to the patient. I have been able to undertake my PhD at the AM4Life Competence Centre where more than 30 universities, companies and hospitals work together side by side to implement 3D printing from prevention/screening to final surgery.

3DN: Any last words for the readers?

I would like to emphasize that innovation in medicine should always be at the service of patients, improving their quality of life through advanced and personalized solutions. At Akira Science, we believe that the future lies in the combination of personalization and transformative innovation, integrating science and technology to respond to real medical needs. We would like to invite readers to follow our path and be part of this revolution in regenerative medicine.

Furthermore, we are convinced that success in this field depends on collaboration between disciplines, where every voice counts and every perspective adds value. We believe in an integrative technology that not only optimizes current treatments, but also redefines the standards of medical care. The future of medicine is being built today and together we can drive it forward! You can learn more about us HERE.

What do you think of Akira Science? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Akira Science