The Top AI Software Solutions for 3D Printing

It seems that nowadays artificial intelligence, or AI as it is more commonly known, is on everyone’s lips. And though there is significant discourse centering on ethical issues with the technology, it is undeniable that AI could be a great tool for many different industries, including 3D printing. Indeed, AI has a role in many different aspects of 3D printing. To shed light on how it is being used, we have compiled the following list of AI software that is compatible with 3D printing. From design to management and quality control, check out the solutions already available on the market below.

Software for Management and Maintenance

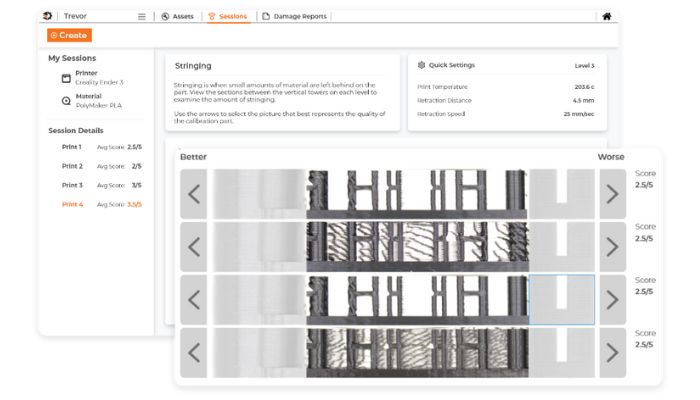

InTinker Uses AI for Better 3D Printing Calibration

inTinker was founded by Trevor Haas and Matt Milanek and is a software that uses AI to make 3D printing calibration easier. Available for both OEMs and hobbyists, this software seeks to create a calibration process that can lower the barrier of entry into 3D printing thanks to customized pre-configured downloadable calibration files and smart suggestions for slicer settings. Essentially, the algorithm works by drawing on results from users, as they test settings and submit feedback it grows smarter and allowing it to in turn give suggestions for calibration while printing parts. Considering the large role that calibration plays in ensuring that printing errors such as with stringing will not occur during the printing process, it could be a useful tool for beginners and experts working with desktop 3D printers.

Photo Credits: inTinker

PrintSyst.ai

Introducing PrintSyst.ai, a cutting-edge artificial intelligence-based management software solutions designed to enhance the quality of 3D printing. This innovative solution conducts pre-tests on digital additive manufacturing models, effectively identifying and rectifying potential performance issues. By ensuring the functionality of final parts, PrintSyst.ai streamlines the entire 3D printing process. Leveraging the power of AI with a user-friendly interface, PrintSyst.ai generates comprehensive reports containing crucial design and material information. These reports also offer valuable recommendations to minimize trial and error, saving valuable time and resources. Moreover, users receive accurate cost estimates, allowing them to maximize profit margins and anticipate part success and performance.Targeted towards industries like aerospace, defense, and automotive, PrintSyst.ai empowers businesses to harness the full potential of 3D printing. By significantly improving the consistency and reliability of final parts, this tool gives companies a competitive edge in the marketplace.

Photo credits: PrintSyst

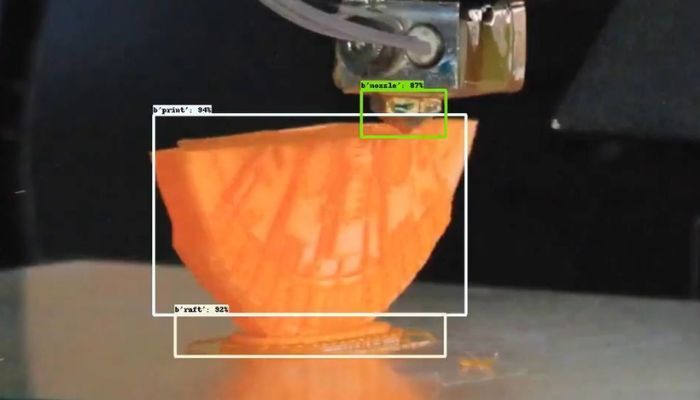

PrintNanny

PrintNanny is another AI-powered monitoring and automation software solution for 3D printing. It eliminates the need for constant supervision by providing quality control that never sleeps. Users receive notifications or can choose automatic pauses if a print job fails to pass quality control standards. PrintNanny OS serves as the operating system for 3D printing, allowing users to easily install it on Raspberry Pi and integrate their favorite 3D printing tools. Over-the-air updates keep all tools up-to-date without the hassle of re-imaging SD cards. With flexible pricing options and custom packages available for enterprise, PrintNanny offers a comprehensive solution for efficient and streamlined 3D printing operations.

PrintNanny automatically halts failed 3D print jobs (Photo credits: PrintNanny)

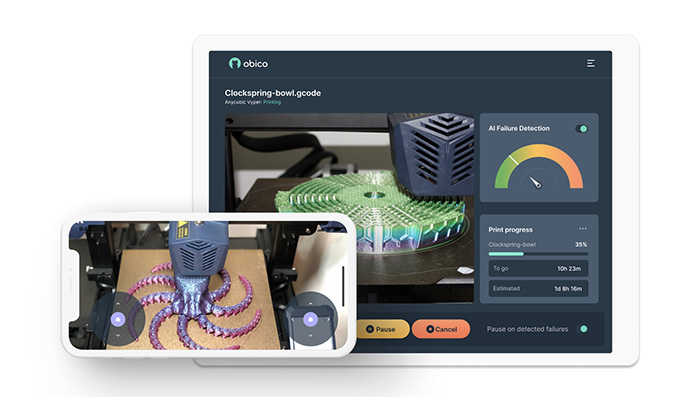

Obico.io

Obico’s primary objective is to provide users with easy and remote control over their 3D printers. Previously known as The Spaghetti Detective, this platform is specifically designed for the 3D printing community and offers an open-source and intelligent solution. Leveraging the power of artificial intelligence, Obico excels in detecting potential failures during the printing process. The AI system thoroughly analyzes all prints that are initiated and promptly identifies any instances of failed prints. Once a potential anomaly is detected, the tool sends an alert to the user’s phone, ensuring timely intervention and preventing further material wastage. This not only saves manufacturers valuable resources but also offers peace of mind during the part manufacturing process. Impressively, Obico’s artificial intelligence system has successfully detected nearly a million prints, further solidifying its reliability and effectiveness in ensuring smooth 3D printing experiences.

Photo credits: Obico

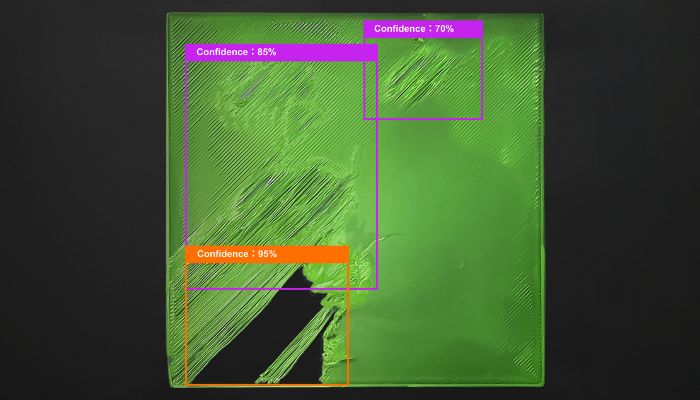

PrintWatch

Printpal.io is on a mission to enhance the accessibility and efficiency of 3D printing through their cutting-edge AI software solution, PrintWatch. Powered by Artificial Intelligence technology, this software boasts the ability to detect errors and defects in real-time during 3D printing, while also optimizing autonomous printing. By doing so, it streamlines the printing process, saves time, and reduces material wastage.One of the most remarkable features of PrintWatch is its exceptional accuracy in error detection, claiming an impressive rate of over 93% for each printer, material, and color. With this level of precision, users can rest assured that potential issues will be promptly identified, enabling them to take timely action and avoid costly defects. Moreover, PrintWatch offers users the convenience of remote 3D printing management. As soon as an error occurs, the user is instantly alerted, allowing for quick intervention and effective troubleshooting. The software comes in three pricing categories, with the standard version being available free of charge, making it an accessible tool for a wide range of users seeking to optimize their 3D printing processes.

AiSync

AiSync, a cutting-edge AI-powered solution developed by the renowned London-based SAAS company Ai Build, is revolutionizing additive manufacturing processes with its mission to enhance speed, quality, scalability, and process reproducibility. Offering accessible and user-friendly features, AiSync simplifies the entire printing process while boosting efficiency.Through a user-friendly chat window, print order parameters are seamlessly entered in text form, allowing AiSync to create a precise programming path. Gone are the days of laborious manual coding, as visual programming takes center stage, making printer parameter input clear and straightforward. This empowers users to access advanced printer tools with ease, ensuring optimal control over the printing process.

Using a digital twin for visual simulation, AiSync supports an extensive range of 3D formats, including OBJ, STEP, STL, 3MF, and GLTF. The advanced version, AiSync PRO, further elevates the experience with real-time control. By integrating seamlessly with machines and continually analyzing the printing process, users receive timely notifications on print quality, enabling them to monitor progress at any given moment.Designed primarily for industrial production, AiSync solutions cater to diverse sectors like aerospace, automotive, construction, and shipbuilding. Raving customer feedback attests to the remarkable benefits of AiSync, with print setup times reduced by 86% and total production time slashed by 90%. As the industry embraces AiSync, additive manufacturing takes a giant leap forward, delivering unparalleled efficiency and superior output quality.

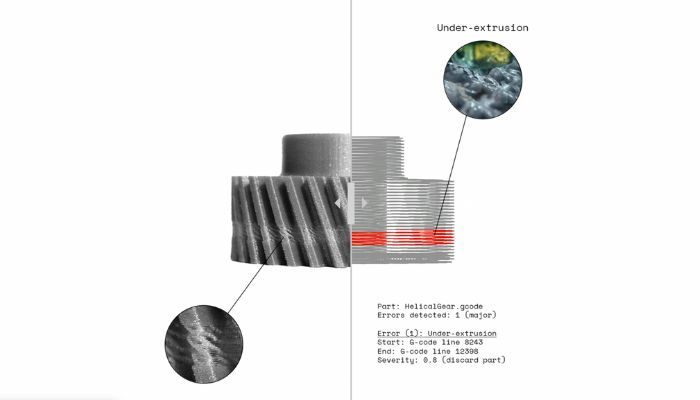

PrintRite3D

Addressing one of the most significant challenges in the additive manufacturing sector, Sigma has developed PrintRite3D, a robust quality tool poised to revolutionize the industry. By focusing on in-process quality control – encompassing machine status, process status, and part status – PrintRite3D centralizes and correlates essential data in a single platform. This integration of sensor values enhances error detection reliability, aids in cause analysis, and minimizes potential damages.Functioning as a real-time monitoring tool, PrintRite3D boasts an advanced analysis solution ideally suited for modern 3D metal and polymer technologies. Throughout the manufacturing process, it diligently detects defects and anomalies, mitigating error-related costs and elevating production efficiency and cost-effectiveness.

Versatility is a key strength of PrintRite3D, as it seamlessly integrates with various printers, independent of the brand. Compatible with all major metal and polymer printers, the tool becomes an essential asset for additive printing companies seeking to establish and uphold stringent quality standards.As Sigma sets its sights on elevating metal and polymer 3D printing to new heights, PrintRite3D emerges as the catalyst that will empower the industry to overcome quality assurance hurdles and unlock the full potential of additive manufacturing.

Sigma’s PrintRite3D tool analyzes the printing process in real time, enabling anomalies to be corrected directly, saving time and money (Photo credits: Sigma Additive Solutions).

Grey-1 from Matta

Matta, a London-based company, has harnessed the potential of deep learning software to revolutionize the 3D printing process. Introducing the Grey-1 self-learning AI platform, Matta sets a new standard by not only detecting errors in real time but also proactively correcting them and identifying their root causes. Swift and precise control algorithms allow for instant correction of incorrect parameters, ensuring a consistent and superior print quality.When it comes to working with new or unfamiliar materials, Matta’s AI platform is a game-changer. Within seconds, the AI learns and adapts to print these materials flawlessly by determining the optimal processing parameters. This adaptability guarantees optimal performance, regardless of the material’s complexity or uniqueness.

Additionally, Matta’s Grey-1 platform offers robust quality control capabilities by detecting printing errors and generating a digital twin of the part. This innovative approach allows for quality measurements to be projected onto each extracted layer, ensuring stringent quality standards are met throughout the printing process.With the platform’s waiting list now open for registration, the industry eagerly anticipates the transformative potential of Matta’s Grey-1 AI platform, which promises to revolutionize 3D printing with unprecedented efficiency and accuracy.

Photo credits: Matta

DeepCube

DeepCube® AI Software revolutionizes additive manufacturing with its deep-learning capabilities. Its pioneering inference accelerator dramatically improves performance on additive manufacturing hardware. The software enables real-time error detection and correction, surpassing human capabilities by identifying imperceptible defects. This leads to improved part quality and increased yield. DeepCube’s proprietary algorithms provide quick data analysis speeds, optimizing memory usage and overcoming infrastructure limitations. With seamless integration into edge devices, DeepCube empowers machines to actively control production. Its distributed global automation transforms 3D printers into a comprehensive solution for Industry 4.0, enabling coordinated operations and knowledge sharing across the network.

Photo credits: DeepCube

BambuLab’s Micro Lidar

Bambu Lab, the manufacturer of 3D printers, incorporates advanced artificial intelligence into its Bambu Lab X1 series with the integration of the Bambu Micro Lidar. The sensor operates autonomously, conducting a thorough inspection of the initial printed layer to identify defects, including the detection of “spaghetti monsters.” Additionally, the system uses an algorithm to check and adjust the nozzle height, while also providing an extra calibration check.

Photo credits: Bambu Lab

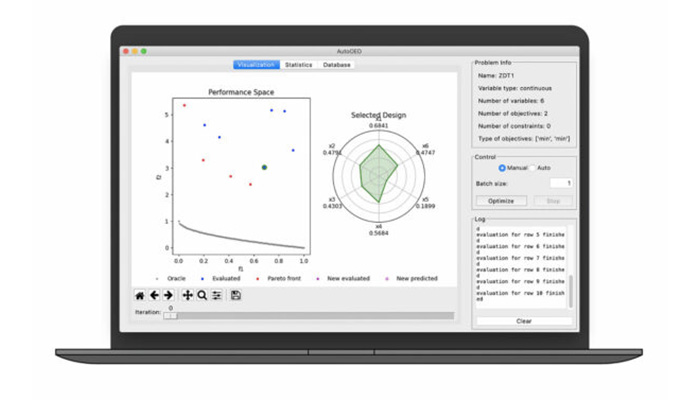

AutoOED

AutoOED serves as experimental design software, harnessing the capabilities of an artificial intelligence system, similar to other solutions on this list. It proves to be a potent tool for enhancing design parameters across various experimental settings. What sets AutoOED apart is its user-friendly and straightforward design, catering to users with little to no prior knowledge. The software proudly embraces an open-source approach, enabling customization and the creation of novel algorithms. It’s worth considering that the optimization speed may vary based on the chosen algorithm, but, notably, many of them execute swiftly and efficiently.

Photo credits: AutoOED

Software for Design

NVIDIA Picasso

NVIDIA Picasso is an innovative cloud service designed for building and deploying generative AI-powered visual applications, including images, videos, and 3D content. This powerful service enables enterprises, software creators, and service providers to leverage the capabilities of generative AI. With NVIDIA Picasso, users can run inference on their own models, train NVIDIA Edify foundation models using proprietary data, or start from pre-trained models to generate visual content from text prompts. The service is fully optimized for GPUs and streamlines training, optimization, and inference on NVIDIA DGX Cloud. By using NVIDIA Picasso, organizations can supercharge their applications with generative AI, offering custom models, interactive experiences, and cost-saving inference optimizations. Additionally, partnerships with industry leaders like Adobe, Getty Images, and Shutterstock open up new possibilities for creators and marketers to accelerate their workflows and access licensed data for training models. NVIDIA Picasso has already showcased success stories with companies like Runway, Cuebric, and WOMBO, empowering users to explore new frontiers of creativity and visual content generation.

Photo credits: NVIDIA Corporation

DreamFusion

DreamFusion is a software that transforms text into a 3D printing model. It harnesses an AI-driven text-to-image model called Imagen to optimize a 3D scene. Through the Score Distillation Sampling (SDS) technique, it generates samples based on a diffusion model, enabling optimization within a flexible parameter space, like a 3D environment. DreamFusion employs a 3D scene parameterization akin to Neural Radiance Fields (NeRFs) for this mapping, and further includes additional regularizers to enhance the geometry. The resulting trained models exhibit consistency and boast high-quality surface geometry and depth.

Photo credits: DreamFusion

Do you have any experience with these AI software for 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.