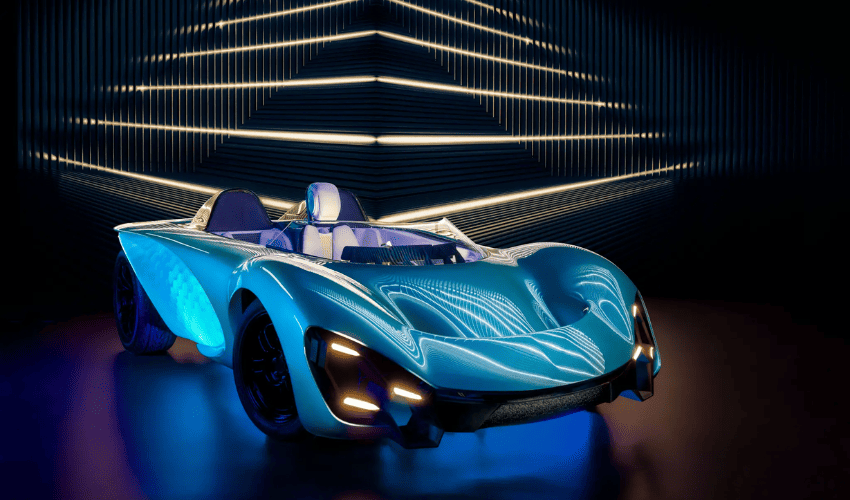

The Aether Concept Car Pushes the Boundaries of Automotive Design With 3D Printing

The automotive industry is increasingly moving towards sustainable solutions, with 3D printing playing a key role in this transition. The Aether concept car was created with this in mind. This next-generation electric vehicle incorporates advanced technologies, such as digital modeling and additive manufacturing, to rethink its design.

The Aether concept car was created by students at Savannah College of Art and Design (SCAD) for Gen Z drivers, with a focus on the environment, technology and personalized design. Led by designer Rafael Corazza, the project features modular interiors and innovative exterior surfaces, combining ecology, technology and unique aesthetics.

3D Printing to Make the Aether Concept Car

The Aether concept car took advantage of parametric design and 3D technologies. In particular, HP’s Multi Jet Fusion process was used to create components that were both aesthetically pleasing and practical, such as speaker grilles, headrests and cushions. For these specific parts, the SCAD team used Rhino 3D’s Grasshopper tool to design custom structures, which were then 3D printed using a flexible material, BASF’s TPU 88A. This material, a thermoplastic polyurethane, offers great flexibility and strength, ideal for parts requiring both flexibility and robustness.

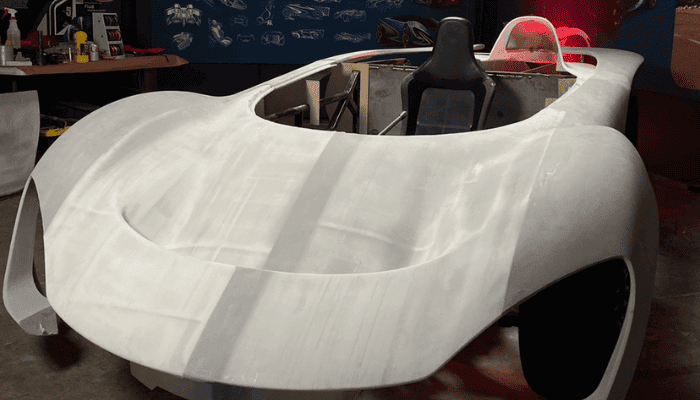

The team, guided by student Lilian Brown, worked on interior elements combining ergonomics and design. By combining custom latticework and flexible 3D-printed TPU, they succeeded in creating practical, solid pieces. For the exterior, the students designed digital models via Rhino 8 and fabricated physical prototypes using 3D printing.

During the design phase, the students carried out between 15 and 20 iterations before finalizing the Aether’s exterior appearance. Despite the challenges of aligning the hexagonal elements and optimizing for printing, the team persevered and chose a simplified extrusion method to speed up the process. The main outer panels were 3D printed using UV-treated acrylic gel, with wall thicknesses of 4 to 6 mm, ensuring both strength and material efficiency.

According to SCAD, “The Aether electric vehicle, developed in Savannah, proposes a new design language that appeals to the Gen Z demographic while paying homage to influential cars of the past, including the Ferrari 312 F1 and the Porsche 917. The vehicle’s racing aesthetic includes an open top and an AI companion that curates music based on driving style. Aether was entirely printed with innovative 3D technology that incorporates acrylic gel photocured with UV lights. This technology was a key element to the success of developing the car in record time, making Aether the first car ever built using this technology.” An incredible feat in the field.

What do you think of the Aether concept car? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Rhino 3D