Top Additive Manufacturing Workflow Software Solutions

The increasing integration of 3D printing across industries has brought about a pressing need: the effective management of diverse additive manufacturing workflows. In response, specialized Manufacturing Execution System (MES) software tailored for 3D printing has emerged. The primary objective is to streamline and automate the entire manufacturing process, ultimately enhancing productivity. These software solutions offer a comprehensive array of features, with a focus on five key areas: product tracking, order management and scheduling, quality control, traceability, and machine maintenance, facilitated by real-time data analysis. Today, we showcase the available additive manufacturing workflow management solutions in the market, empowering you to harness the full potential of this technology.

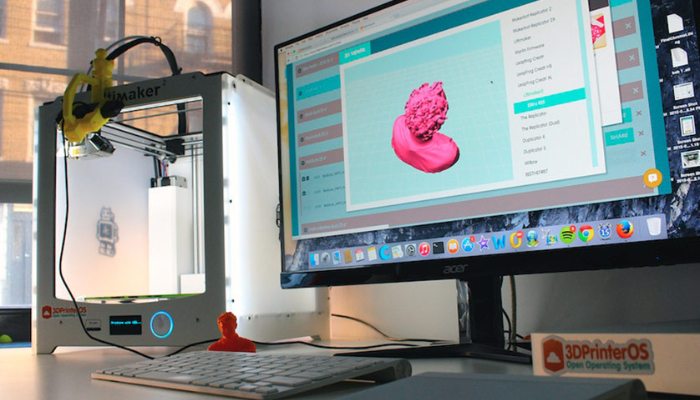

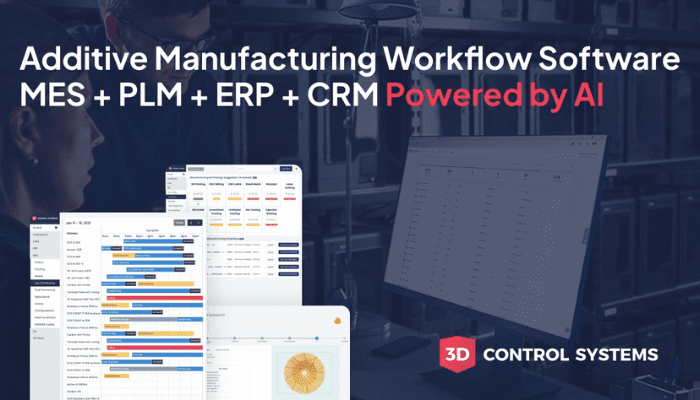

3DPrinterOS

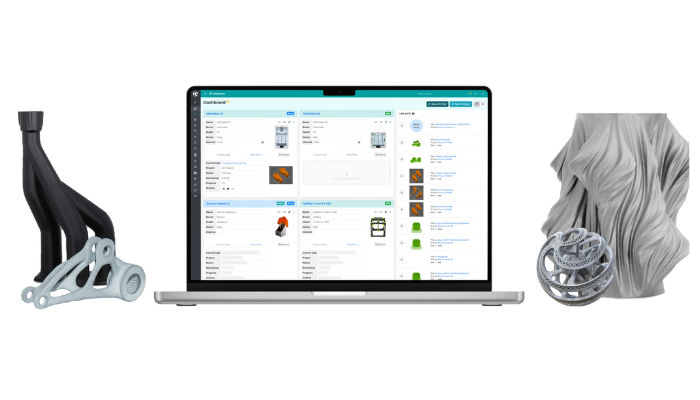

3DPrinterOS belongs to the 3D Control Systems group and offers a software solution for managing your additive manufacturing production. It offers a wide range of functions, including file preparation, a slicer, a 3D printer failure detection system, and more. Of particular interest to us today is the ability to control the number of printing hours per user, define manufacturing priorities and share projects between machines. In this way, 3DprinterOS gives you greater control over your production by making informed choices in terms of print time, load distribution, etc. The software is currently compatible with a wide range of desktop 3D printers.

(Photo Credits: 3DPrinterOS)

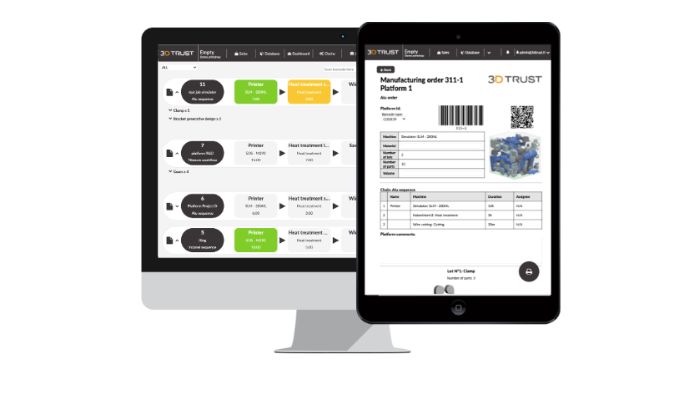

3D Trust

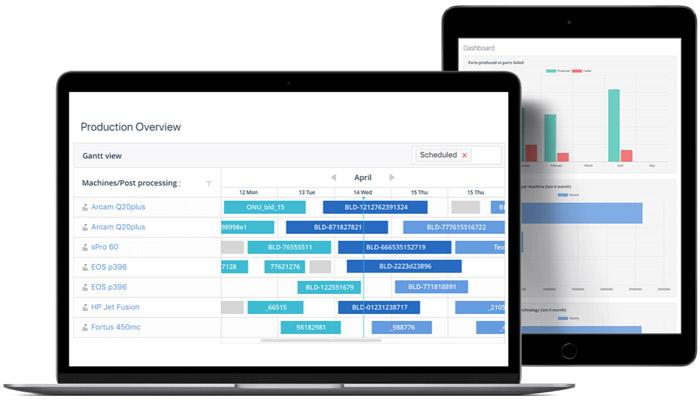

3D Trust, acquired in 2021 by software developer Bassetti Group, is a software for additive manufacturing that optimizes the entire workflow with the purpose of intensifying the use of 3D technologies in factories. The solution supports all major brands of industrial printers and the entire value chain, from order taking to delivery, including real-time data collection to identify failures in printing and post-processing. The user can thus maximize profitability and increase traceability. Among the main features of 3D Trust is an automated production schedule that, thanks to an algorithm, defines priority tasks. It also features a tracking and traceability system consisting of a unique QR for each printed part. The solution, available for tablets and smartphones, offers efficient management of the materials used, especially powder. The system allows the scanning of printer containers to ensure that the material is used in the best way and according to internal guidelines such as storage conditions or screening. In addition, every action is recorded in a complete history, and reports are generated automatically.

(Photo Credits: 3D Trust)

3YOURMIND

Included in this roster is the software from 3YOURMIND, a crucial addition. Their comprehensive on-demand additive manufacturing solution empowers users to identify and produce parts seamlessly, anytime and anywhere. Specifically engineered to optimize on-demand production across the entire product lifecycle, the software addresses the imperative of companies to manufacture parts swiftly, with reduced weight, and cost-saving potential. 3YOURMIND offers three distinct versions tailored to individual user requirements: “Professional,” “Professional+,” and “Enterprise,” each progressively enhancing features and functionalities. Targeted at OEMs, operating companies, and contract manufacturers, the software enables the creation of digital inventories of qualified parts, fostering more efficient and agile operations.

(Photo Credits: 3YOURMIND)

AM-Flow

AM-Flow is a Netherlands-based company offering complete industrial automation solutions for additive manufacturing technologies, particularly for companies printing more than 200 parts with complex geometries per day. AM-Flow is mainly used after printing, in post-production, and eliminates the need for manual sorting of printed parts by an employee, which can lead to high costs in terms of personnel and physical space. The company explains that this reduces the risk of errors, resulting in significant time savings. The company also offers the option of a “pay as you grow” program, which means that start-ups have to pay less than much larger companies.

(Photo Credits: AM-Flow)

AMFG

AMFG offers a tailor-made production management platform, adapted to the reality of each company. It meets the needs of rapid prototyping, 3D printing of spare parts or finished parts as well as printing services. The platform can manage and prioritize the different orders, analyze the printability of each 3D model, analyze all the prints launched and program them intelligently. AMFG’s solution integrates with existing ERP, PLM and CAD software, the goal being to have a single additive manufacturing platform with all the necessary tools in one place. You can also get a free demonstration on the AMFG website.

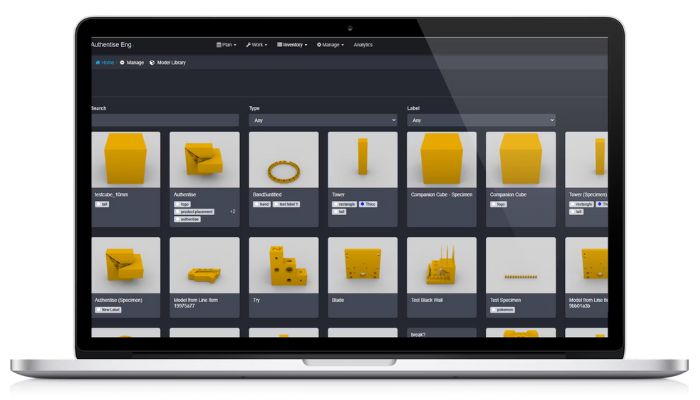

Authentise

Authentise is an American company that has developed its production management software solution for both OEMs and service companies. Called Authentise Manufacturing Execution System, it allows to collect real time data of the additive manufacturing process and to increase its reliability. For example, for OEMs, it offers several functionalities such as centralized order taking and subcontracting, production planning, an online 3D model library, daily reporting, and real-time machine monitoring. Authentise’s solution would allow each user to reduce lead times by automating manufacturing processes and reduce production costs – between $0.35 and $48 per part. You can get a free demonstration of the platform on the company’s official website.

Fabpilot

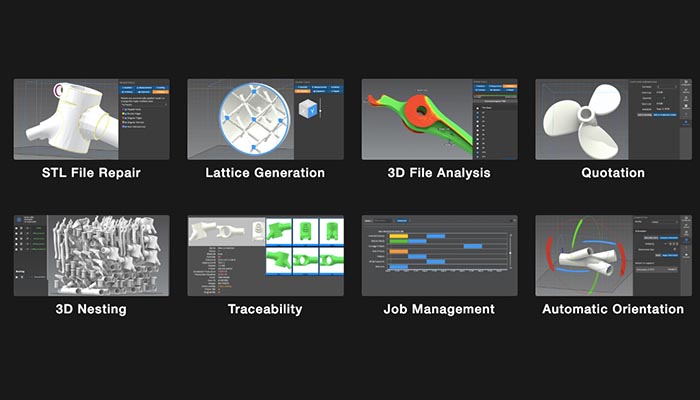

Fabpilot

Fabpilot is an intelligent additive manufacturing software launched by Sculpteo. The software offers a complete solution for 3D printing and workflow management to support AM factories at whatever scale they operate. Some of tools include typical tools in AM software to prepare for 3D printing, such as STL file repair, 3D file analysis but also lattice generation. To this, Sculpteo has added some additional tools such as quotation, traceability, and job management. Therefore, on a single platform you will be able to streamline all operations and reduce waste by combining additive manufacturing with automation. After going through production, Fabpilot enables a company to get up-to-the-minute insights into performance thanks to its data driven tools.

Fabpilot’s tools for workflow management

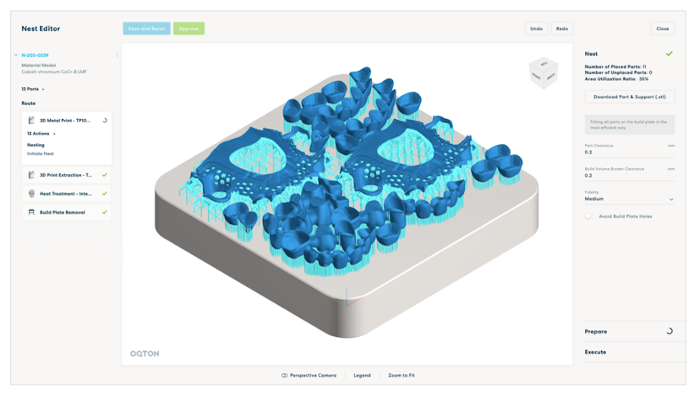

Oqton’s FactoryOS

FactoryOS is a cloud-based, AI-powered workflow software created by global startup Oqton. This enterprise-wide software links data across the additive manufacturing ecosystem – from design to production. Oqton FactoryOS can be targeted to specific industry verticals as well as different workflows within those industries. The platform offers these specialized verticals in medical, industrial and aerospace 3D printing, with the main focus being on jewelry and dental markets. The AI algorithms enable the system to continuously learn with use, improving production efficiency and quality; it works in the background to feed customizable modules that present data relevant to specific operational roles.

Print & Go

Print & Go offers a complete solution for automating the management of 3D printers and the manufacturing process, providing a flexible approach. Featuring a comprehensive dashboard, Print & Go enables users to monitor their operations in real-time and use predictive analytics to make informed decisions. Thanks to its AI-based error detection system, this solution can reduce errors by up to 30%, improving the success rate of 3D printing projects. Access your prints remotely from any device and get a detailed analysis of your production. In addition, Print & Go provides detailed production analyses, such as productivity efficiency and material consumption, enabling users to turn this data into concrete actions to optimize their processes Finally, Print & Go’s ability to adapt seamlessly to sudden changes in priorities ensures agile and responsive management of 3D printing production.

(Photo Credits: Print & Go)

Siemens Opcenter

Siemens’ Opcenter Execution MES solutions represent a strategic move towards streamlining manufacturing processes, including 3D printing and other production methodologies. The overarching goal is to curtail lead times, enhance resource utilization, and amplify productivity across operations. The product we’re interested in is called Opcenter Execution Discrete. In particular, it can be used to control complex and growing production lines, to control the workforce, and to centralize key data generated on the shop floor. Although not specifically designed for additive manufacturing, Siemens’ solution is comprehensive and should guarantee satisfactory results. It is particularly used in the defense, automotive, and aerospace sectors.

The Software ZAP

ZAP, an AI-optimized workflow software, represents an innovative solution for 3D printing. Its Machine Connectivity feature makes it easy to connect 3D printers for complete traceability. Real-time workflows dramatically reduce the latency between design and manufacturing. With support for over 1,500 machines, ZAP offers flexible integration. Features include intelligent part prioritization, post-processing planning and machine connectivity for efficient management of 3D printing production.

Have you used any of these additive manufacturing workflow software solutions? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news on progress, research and more entrepreneurs in 3D printing send straight to your inbox!

Great overview of the additive manufacturing workflow software landscape! This article effectively highlights the critical role these solutions play in optimizing 3D printing processes. It’s interesting to see how far the software has come in managing everything from design to production

https://www.paanduvapplications.com/what-is-additive-manufacturing

Great blog! This is a comprehensive overview of additive manufacturing workflow software solutions. Given the variety of features across platforms, which solution do you think offers the best balance between automation and customization for mid-sized manufacturers? Also, how do these software solutions compare in terms of ease of integration with existing MES/ERP systems?