Additive manufacturing to treat polluted waters

As we know, nowadays 3D printing offers the possibility of creating complex objects that can be reproduced quickly, easily and without much effort. With this idea in mind, a research team from the universities of Tasmania and the Balearic Islands decided to use this technology to purify polluted water. Andreu Figuerola, Fernando Maya and Gemma Isabel Turnes, are the authors of this project, which was funded through the Spanish State Research Agency (AEI) and the European Regional Development Funds (ERDF). It is interesting to know how additive manufacturing methods are increasingly present in the fight against environmental pollution, and how many organizations are integrating this technology to launch initiatives that contribute to this movement.

Unfortunately, it is not uncommon to hear news about different incidents that lead to environmental damage and pollution. For example, not so long ago, there was an environmental disaster in Spain, when the Mar Menor suffered. Mar Menor is a coastal saltwater lagoon, in which thousands of organisms were devastated due to the effects of pollution of anthropogenic origin. As a result, many natural ecosystems have been destroyed. Water, being absolutely indispensable for humans needs special attention and care. But how did the researchers manage to integrate additive manufacturing into the water purification process?

Image credits: Marcial Guillén/EFE

Additive manufacturing for water treatment

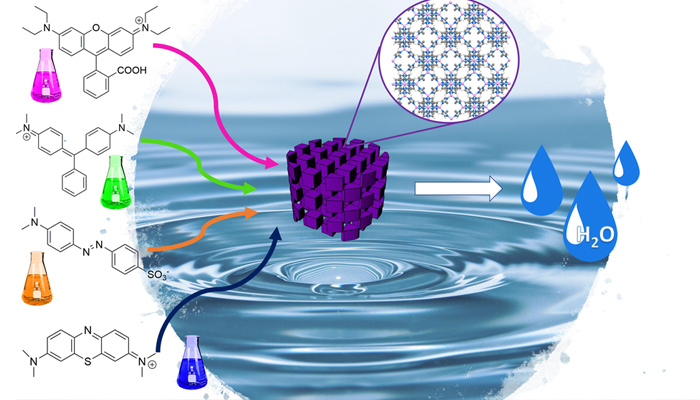

To treat the water, there exist several methods consisting of quite a few stages that depend on the origin of the water (fluvial, industrial, residual, etc). In our case, the research team used 3D printing to manufacture devices coated with adsorbent materials capable of purifying aqueous solutions with different industrial dyes. In other words, they developed a support piece consisting of a module with interconnected channels to incorporate the adsorbent materials. The complex design increases the surface area within the module and, therefore, the amount of material that can be included.

Although difficult to use, adsorbent materials have the advantage that they can be modified to remove one or more contaminants. However, 3D printing does not offer great possibilities in this context because the parts obtained are not adsorbent. This is why the project sought to combine the two tools in order to highlight the advantages in a single solution that would maximize the benefits for both parties. How did they achieve this? They incorporated the substances into the surface of the device right at the end of the manufacturing process, when the part is still soft and sticky. Thus, by simple contact, they were able to deposit a synthesized adsorbent carbon on the surface. In order to verify the effectiveness of the device, they tested a series of solutions prepared in the laboratory with different dyes for industrial use.

The 3D printed device integrates adsorbent materials to remove contaminants.

What was the result? The team obtained a total loss of color in less than 24 hours due to the adsorption of the dye by the 3D printed device. In another test, they used a synthetic membrane to connect the 3D printed parts and the adsorbent material. The results were satisfactory because the discoloration took less than half an hour and the process could be repeated several times. This made it possible to demonstrate that the device could be constantly reused. In conclusion, the team was able to incorporate the materials using 2 different processes, giving them qualities they did not have before. Overall, it became clear that the 3D printed device can be effective in removing pollutants and thus contribute on a large scale to the purification of contaminated waters in the long term.

What do you think about additive manufacturing for water treatment? Let us know in a comment down below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!