The Cumulative Benefits of Additive Manufacturing: The True Added Value of the Technology

In its latest report on trends in additive manufacturing, Jabil drew up a picture of the uses and practices of more than 300 professionals who have decided to bet on 3D printing. A few months later, it looks back at the main applications of the market by asking the following question: what is the real value of additive manufacturing? Is it in rapid prototyping? Is it in tooling applications? How do we measure its impact on the entire value chain? While many believe that the impact of additive manufacturing lies in the product development phase, particularly in terms of cost and time, in reality, according to Jabil, one should analyze the ongoing, cumulative downstream benefits of the technology, regardless of the application.

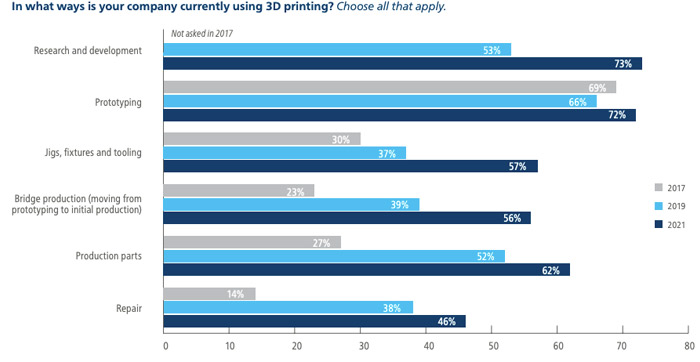

In terms of the use of additive manufacturing, the current trend is toward industrialization, with more production of small and medium-sized runs of finished, ready-to-use parts. Users are looking for repeatability and automation in their processes to increase the printing of finished parts – in fact, 81% of participants in Jabil’s study expect the use of 3D printing for production to at least double in the next three to five years. Rapid prototyping remains the most important application when evaluating different market shares, but it is stagnating.

How is 3D printing used in businesses? Prototyping is often the first application (photo credits: Jabil)

The Added Value of 3D Printing in the Prototyping Phase

The use of 3D printing in rapid prototyping is obviously beneficial in terms of cost and time: teams can design iterations faster, test and evaluate multiple concepts easily and correct any defects in record time. These are widely known benefits that have led to the adoption of additive manufacturing in-house for many companies. But we need to broaden the scope and consider the entire value chain.

The added value of additive manufacturing in rapid prototyping would be more after the finished product has been brought to market. As the design cycle has been reduced and improved, a better result should be achieved, a more competitive product. Jabil states that the company’s brand image should be strengthened by higher customer satisfaction. Revenues and margins increase thanks to an improved prototyping phase. It’s a virtuous circle according to the report.

Tooling and End Parts

In the Jabil study published in 2021, the use of additive manufacturing for tooling has increased by 20% compared to 2019 and 33% of participants say it has a positive impact on the design of tools and jigs. The added value of 3D printing lies mainly in production lines: it avoids slowdowns, downtime and consequently, significant financial losses. Production is carried out internally, eliminating long supply chains, physical stocks and also lead times. Additive manufacturing will therefore have an immediate positive impact and increase the efficiency of production lines.

By 3D printing their tools, companies reduce downtime on their production lines (photo credits: Ultimaker)

When it comes to producing finished parts through additive manufacturing, the story is similar: it’s an application that has grown significantly in recent years. John Dulchinos, vice president of digital manufacturing at Jabil, explained, “3D printing technology is getting better and more cost effective every year. The break-even points this year are 10, 20, 30% better than last year. We’re going to continue to see that kind of compounded annual growth rate.” 3D printing users are noting better returns on investment which is driving them to employ it for applications beyond prototyping. According to Jabil’s study, more than 50% of participants say they use additive manufacturing to produce more than 50,000 parts per year, and for 20% that number rises to 100,000.

Like rapid prototyping, the added value of additive manufacturing lies in the possibility of offering more competitive products, with improved performance and functionality, all of which can be used to build a better brand image. This is closely linked to the design phase: Design for Additive Manufacturing (DfAM) is surely one of the components that brings the greatest added value.

Design in Additive Manufacturing

The design part of additive manufacturing has positive impacts on the whole value chain: whether it is for production, maintenance or sales, it brings real differences compared to traditional processes. One could say that this is finally where the added value of additive manufacturing lies. When you think about it, the different design techniques in 3D printing allow to create more complex geometries without sacrificing functionality, to save material without affecting the strength of the part. It is also thanks to the design that a user will be able to reduce the assembly steps and therefore the manufacturing time.

The cumulative benefits of additive manufacturing (photo credits: Jabil)

The company concludes, “While additive manufacturing provides both clear cost and timing advantages in multiple, discrete stages in the product lifecycle, the cumulative benefits that have a multiplying affect over the total life of a product are far more meaningful. We expect these benefits to grow as new metal additive manufacturing materials or engineered additive manufacturing materials with custom mechanical properties are introduced.” You can download the entire Jabil study HERE.

In your opinion, where is the real added value of 3D technologies? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Trumpf