Additec Revealed Desktop Metal 3D Printer: μPrinter

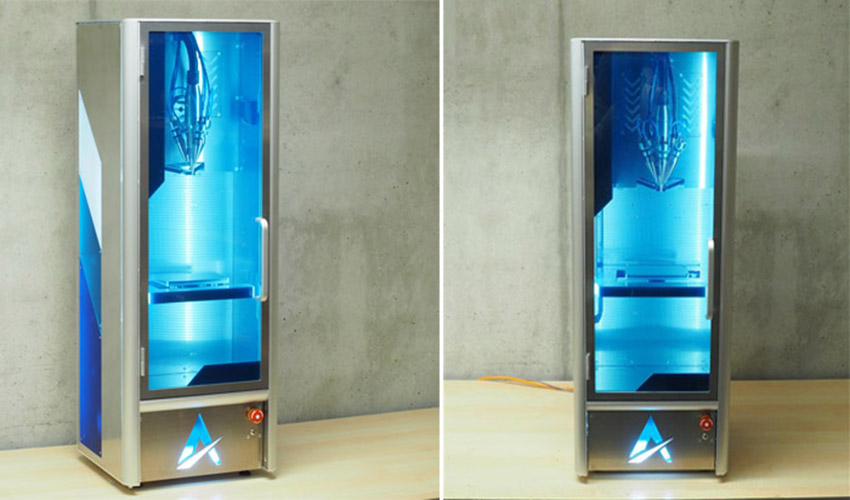

Additec, founded in 2015 is a company based in Las Vegas (USA) and Bremen (Germany). It initiative aims to innovate how large metal structures are manufactured by changing system reliability and cost. They have revealed their new desktop metal 3D printer, the Additec μPrinter.

Additec’s Desktop Metal 3D Printer

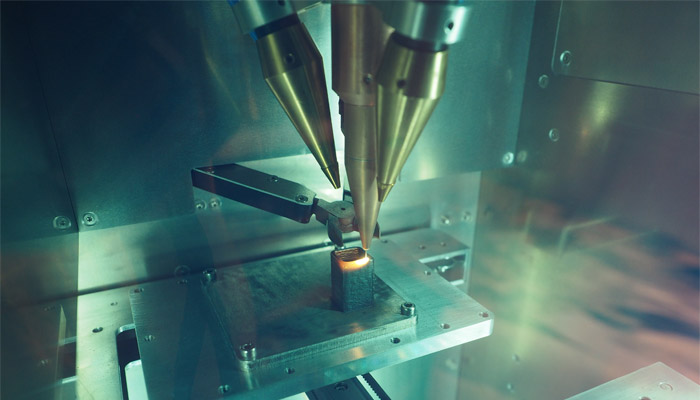

It is one of the most compact metal 3D printers on the market. It is capable of depositing wire and powder feedstock into complex geometries, all while fitting onto a desktop. It uses its patented laser metal deposition (LMD) process, a form of directed energy deposition (DED) technology. In other words, a powerful laser melts a jetted stream of metal powder as it makes contact with the surface of the part, building up the repetitive layers.

Industry and Research Possibilities

They claim their system is perfectly suitable for industry use. It is a stable process, with integrated monitoring and many automated features making it accessible to companies looking to get started in metal 3D printing. It can easily be scaled up with a larger Additec 3D printer, or Hybrid CNC conversion to make very large components. At the same time it allows to be used for cladding or repair of small components. Finally, it can be used for research purposes and development applications.

Metal 3D printing has experienced a large increase in popularity and many manufacturers have started invested in developing more accessible solutions. The uPrinter from Additec starts at $90,000. Even though not the cheapest option, it remains one of the lowest prices on the market for metal additive manufacturing, especially considering its laser technology.

μPrinter Technical Specifications

The printer comes with three laser diodes, 200W each, giving a total output power of 600W. You can add up to 5 lasers to the machine. Each laser is equipped with a visible aiming beam making alignment of the head onto existing structures very easy. As mentioned previously, it is also equipped with a singled material Wire feed system. The printer is 100% material efficient and can fit 0.6 mm to 1 mm wire diameters, spooled on up to 300mmm commercial MIG Spools. The printing volume is 160mm x 120 mm x 450 mm. The printing chamber ensures that oxidisation of the printed pieces does not occur.

You can check out the company’s website for more information.

What do you think of this desktop metal 3D printer? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!