Addion Has Designed Ultra-Realistic Eye Models to Help Prepare for Ophthalmological Surgeries

Austrian 3D printing service Addion GmbH, which specializes in the production of 3D printed medical devices, is using Stratasys PolyJet technology to design ultra-realistic surgical eye models to better prepare for critical operations. The multi-material, multi-color additive manufacturing process allows the company to achieve an unprecedented level of realism, a significant benefit of using 3D printing to train for difficult surgeries.

In the ophthalmic sector, it is often difficult to design models that reproduce the soft, watery tissues of human eyes. They often lack realism, especially with regard to color and touch. The eye is a difficult organ to replicate due to its complexity – the process is time consuming and quite expensive. Additive manufacturing can remove some of the barriers when it comes to designing custom surgical models, but some technologies don’t meet all needs, especially in terms of materials, transparency or color. This is where material jetting is particularly interesting: since it can combine several photopolymers and colors, ultra-realistic parts can be obtained.

Photo Credits: Addion/Stratasys

Addion 3D prints a custom eye model

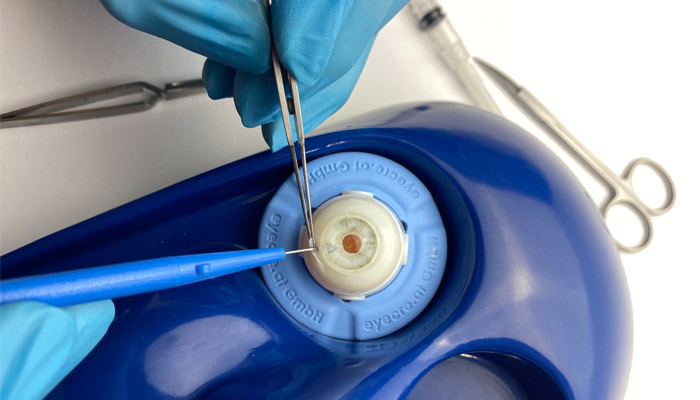

Addion GmbH relies on Stratasys’ Digital Anatomy machine, a solution thought for the medical sector in particular to reproduce the behavior of human tissue. Using TissueMatrix™ and GelMatrix™ materials, the company can mimic the soft, watery appearance of the eye, creating a high level of realism. Alexander Hechenberger, CEO of Addion, explains, “The skin layer on the model is one-tenth of a millimeter and is detached with very small, fine instruments, implanted, and then reattached. This level of detail was previously unimaginable.” Indeed, they are able to produce a surgical model where the cornea can be easily removed: this allows doctors to simulate an operation and better prepare, but also to better understand how the eye works.

Alexander Hechenberger continued: “For us, the possibilities with the Digital Anatomy Printer are endless, and despite the incredible results we’ve enjoyed to date, we are still just scratching the surface in terms of the technology’s potential. There are hardly any comparable alternatives for eye model production in our industry, particularly in the complex recreation of soft tissue with realistic colors and the variety of materials.” The Austrian company already has plans to test other materials such as BoneMatrix™ for the creation of bone structures or TissueMatrix for vascular structures. You can find out more in the press release HERE.

Using additive manufacturing, doctors can better understand the structure of the eye (photo credit: Addion/Stratasys)

What do you think of these ultra-realistic eye models? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!