#3DStartup: AddCat and its 3D Printed Reactors Which Can Purify the Air

Dutch startup AddCat combines metal additive manufacturing and catalytic oxidation to develop reactors capable of effectively purifying air. The startup hopes to reduce harmful industrial emissions and some of the unpleasant odors found in some industries (for example biogas plants, manure and wastewater treatment plants, etc.). Using metal 3D printing, AddCat is able to design structures with high thermal conductivity, large surface area and low pressure drop. Thus, its first reactor is designed to eliminate 95% of the odorous components of polluted air. We met with some of its team to learn more about how it uses additive manufacturing and the associated benefits.

3DN: Could you introduce yourself and your connection to 3D printing?

AddCat was founded in December 2019, based upon a patent written by two of our founders, Marc Evers and John Geus. Marc is a serial entrepreneur in the high-tech engineering, build and manufacturing industry, who was already involved in 3D metal printing very early on and who was also at that time the owner of a 3D metal printing service supplier. John Geus is a seasoned expert and technical leader in in the development of catalyst technologies. Both coming from different industries, they started to exchange ideas in which Marc suggested free-from design production methods of 3DP and John immediately recognized the advantages for various industrial catalytic process. This sprouted to the filing of a few patents for the process intensification of these catalytic processes. In the years after, Jacco Hoekstra (a PhD student under John Geus) was already putting some free-time in every week in for initial tests and a proof-of-principle. Gerald van Santen worked with Marc as a project manager and was appointed on a small project where Jacco was working on as well. This finally led to the start of AddCat to bring this innovation to the air purification market.

On the left, Jacco Hoekstra, the CTO of AddCat; on the right, Gerald van Santen, CEO of the startup (photo credits: AddCat)

3DN: What is AddCat’s mission?

For industries struggling with their malodorous emissions, AddCat provides a reliable, low-maintenance and high-performance air purification technology coupled to a low CAPEX and OPEX. Our mission is to create a world free of harmful and malodorous industrial emissions in which companies and citizens can co-exist in harmony. AddCat is proud of its in-house scientific expertise and product leadership and constantly strives to deliver the promised benefits to its clients through the smart combination of state-of-the-art 3D-metal printing and oxidation catalysis. AddCat’s unique reactor technology delivers a high-performant and cost-competitive air purification solution capable of unlocking the full potential of the end-user (e.g. industrial biogas production plants). Our prime focus is on the abatement of methane, ammonia and malodorous emissions (odor).

3DN: Why has AddCat turned to additive manufacturing?

The use of metal 3D-printing enables us to produce our catalytic reactors with complex aerodynamic reactor designs. This results in optimized flow patterns that result in an intimate contact of the pollutants with the catalyst surface provided in the interior. Only 3D metal printing can be used for the production of these reactor structures, because other traditional subtractive manufacturing techniques fail to deliver the finesse required for their production. This gives us the competitive advantage as it results in smaller reactor size, better process control (thermal conductivity and heat exchange), and lower use of the expensive catalyst material. This is reflected in strong process intensification enabled by the use 3D metal printing.

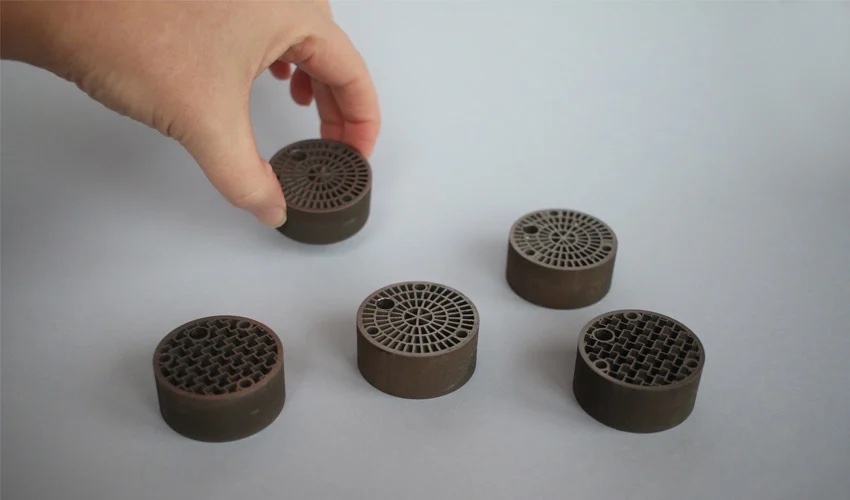

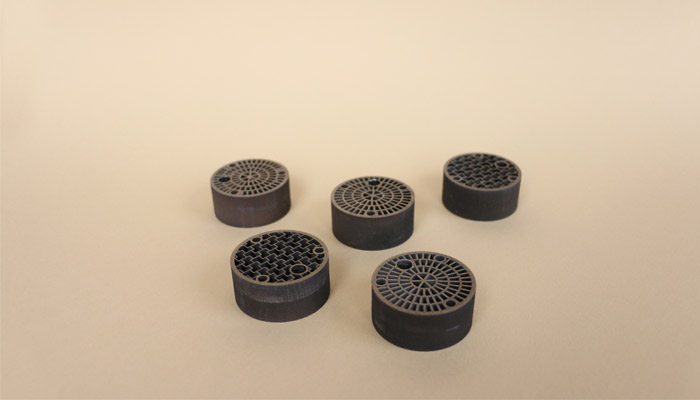

The reactors are 3D printed using different metals (photo credits: AddCat)

3DN: Could you tell us more about how you manufacture your air filters?

In terms of 3D metal printing techniques, we use either direct metal laser sintering (DMLS) or fused filament fabrication (FFF), which both have their pros and cons. For reactor materials, we currently use stainless steel (316L), titanium (Ti6Al4V) or aluminum (Al10SiMg), depending on the particular air purification case. These parts are coated with the catalyst material. We achieve high purification rates of up to and above 95% under a variety of conditions (volumetric flow rates (100-25000 m3/h), high and low level of contaminants (1-10.000 ppm), varying humidities (50-100%), that are present in a wide range of industries. Currently a strong focus is on scaling/industrializing the 3D printing process to enhance mass production. We are working with different partners/suppliers across Europe to reach this goal.

Photo Credits: AddCat

3DN: What markets is AddCat targeting?

In principle, all industries that have hazardous and malodorous emissions from their process. Examples are manure processing industries, biogas plants, the chemical industry, waste water treatment plants and asphalt processing factories.

3DN: What are you future projects?

At the moment we are scaling up our system and implementing market introduction. In terms of 3DP we are innovating with the printing techniques, and multi-material printing approaches by using multi-material filaments for example.

Photo Credits: AddCat

3DN: Any last words for our readers?

With the further industrialization we see that in the coming years 3D metal printing will take the leap to bulk production, which we want to be part of. By the continuous innovation in for example equipment and material development for 3DP we see many more exciting advancements in our reactor technology, and far beyond. You can find out more about AddCAT HERE.

What do you think of our 3D Startup of the Month for August, AddCat? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.