Aconity3D presents its metal and modular 3D printers

Aconity3D is a machine manufacturer based in Aachen, the city is considered to be the birthplace of laser metal 3D printing. The company develops machines for series production that are distinguished by their modular design: they can be customized according to the user’s requirements. Thanks to an online configurator, the customer can choose various options and functions to be integrated directly into the 3D printer, with great flexibility.

Metal additive manufacturing is considered one of the fastest growing and most important market sectors in recent years. This trend has been confirmed by several studies, including Wohler’s 2018 report. Technology offers a multitude of new possibilities, especially for the industry, where it is now possible to design complex custom parts that meet the requirements of many sectors. Customer-specific applications are becoming more and more important, which is why Aconity3D offers on-demand solutions.

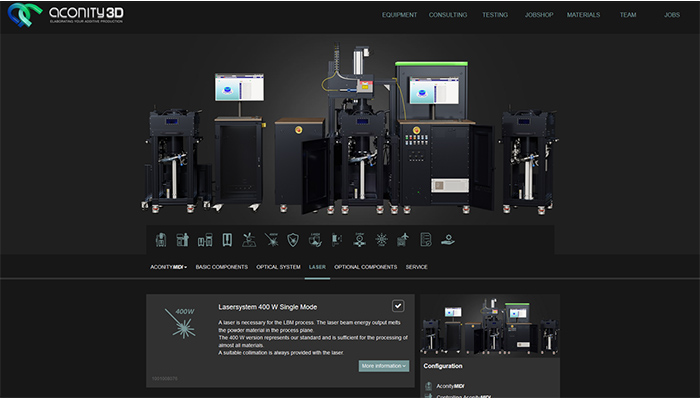

Aconity3D’s online configurator

The manufacturer has therefore developed an online machine configurator with which the 3D printers AconityMINI, AconityMIDI and AconityONE can be flexibly adapted to fit customer’s requirements – much like a car configurator. The differences between the machines mainly concern the size of the build plate and the number of lasers used. All three versions are designed for industrial sectors, the MINI version being a beginner model, the MIDI version a hybrid, which can also be used in R&D, and the ONE version a professional machine for the production of functional finished parts.

Technology and materials mastered by Aconity3D

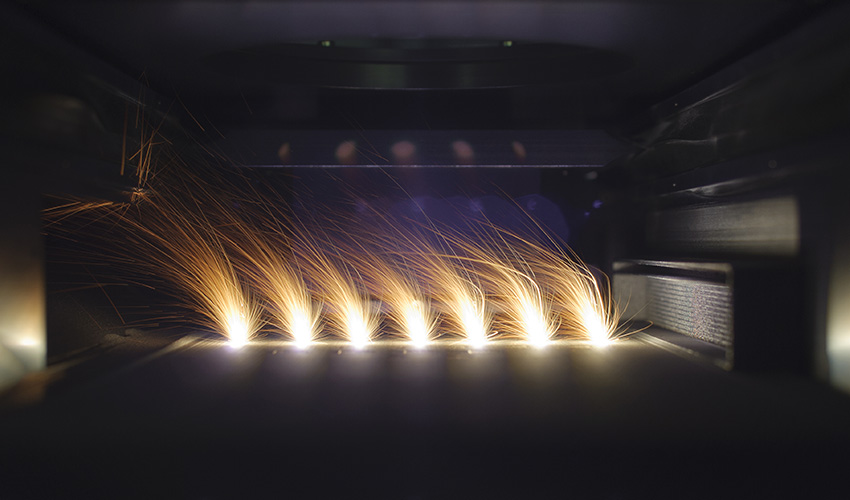

Laser powder bed fusion offers new possibilities in terms of production of resistant and complex metal parts. This technology is particularly suitable for various applications, such as the production of dental models, automotive components or spare parts. However, it appears that the spectrum of materials is still very limited.

If we look at materials, we notice that Aconity3D offers in addition to common metals, aluminum, titanium, stainless steel, nickel-based alloys and chromium-cobalt. This is made possible, for example, by the addition of a special preheating module for the treatment of materials that are considered to be non-weldable. It can heat the tray up to a temperature of 800°C (up to 1200°C on the AconityMIDI). The advantage of this module lies mainly in the reduction of residual stresses, resulting in less cracks and distortions on the final part. Ultimately, materials such as tool steels, titanium aluminides, hard metals and nickel-based alloys can be used, creating new applications.

High temperature process (preheating above 800°C) for the treatment of hard metals such as tungsten carbide

A modular system for manufacturers

Aconity3D offers a total of 16 classic modules for its flexible machines. We told you about the preheating module, but we can also mention the separate treatment chamber, the module for sucking up excess powder, multi-laser systems to increase productivity, etc. Surveillance modules are also available, using pyrometry or a high-speed camera. Print defects can therefore be quickly identified, guaranteeing better stability of the manufacturing process and part quality.

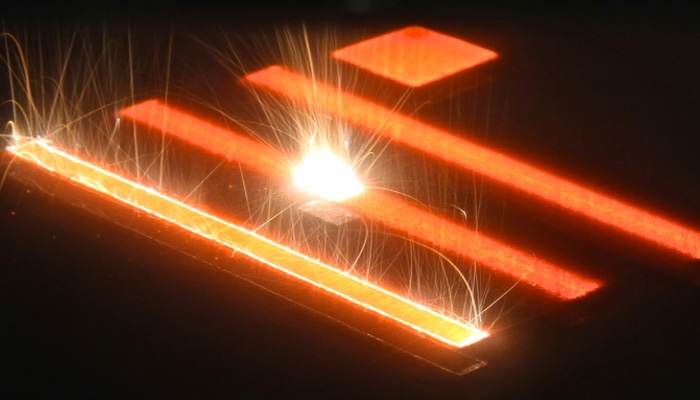

In addition to these standardized modules, Aconity3D offers customized solutions, i.e. modules adapted to the customer’s needs. An example would be the possibility of changing the wavelength of the laser to obtain a green laser source to process pure copper.

Pure copper inductor produced with the custom module that uses green laser radiation to increase material absorption

Aconity3D also offers a consulting service for all its customers, since the company is well aware of the complexity of the manufacturing process. The German company is positioning itself as an innovation partner, supporting the user throughout the additive manufacturing value chain. Dr. Yves Hagedorn, CEO of Aconity3D concludes: “At Aconity3D, we understand that the industrial use of additive manufacturing requires a holistic approach. For this reason, in addition to developing production capacity, we also offer consulting and testing services for full process qualification.“

Find more information on the different modules available on the company’s official website.

What do you think of Aconity3D’s modular systems? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!