A Print Head Built for Medicine: The vipro-HEAD Medical Grade Series

In medical additive manufacturing, much attention is paid to biocompatible materials and regulatory approvals. Yet another factor plays an equally critical role in the success of these innovations: the printhead. As the component that comes into direct contact with the material, a printhead must act with precision and be sterilizable—essential qualities for producing safe, patient-specific solutions. Precision ensures the accurate deposition of complex geometries, while being made of a medical-grade material means meeting the rigorous demands of clinical applications.

As personalized care becomes increasingly central to modern healthcare, the demand for medical-grade additive manufacturing components is rising. To meet this need, ViscoTec Pumpen- u. Dosiertechnik GmbH (“ViscoTec”) has developed a medical-grade series of 3D print toolheads based on its proven vipro-HEAD models. Designed specifically for the medical technology market, these toolheads feature product-contact surfaces made from stainless steel or FDA-certified elastomers and plastics. An autoclavable version is also available, capable of sterilization at up to 121°C, preventing any cross-contamination. Attachable to almost any 3D printer, these print heads ensure seamless integration into clinical workflows.

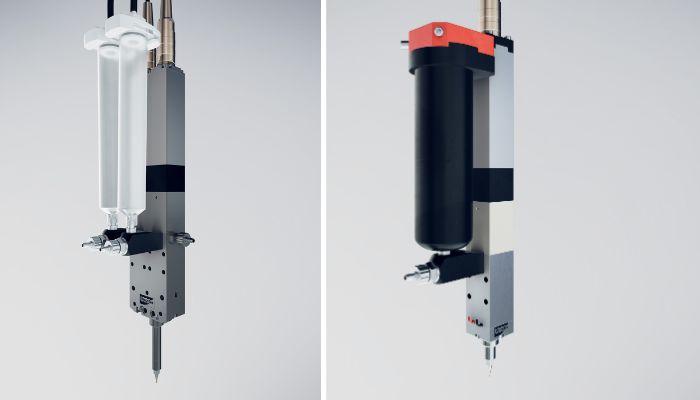

vipro-HEAD for 2-component-materials (left) and vipro-HEAD high-temperature version up to 110 °C (right)

What Does the vipro-HEAD Medical Series Offer?

ViscoTec has long specialized in fluid technology systems, covering everything from material extraction and preparation to the precise dosing of medium to high viscosity media. This expertise translates directly to additive manufacturing, where accurate material deposition is vital. Building on the established vipro-HEAD series, the company now offers medical-grade versions of the following printheads:

- vipro-HEAD 3 and vipro-HEAD 5

- vipro-HEAD 5/5 for two-component applications

- vipro-HEAD 5 with heating function – in a standard version up to 70 °C and as a high-temperature version up to 110 °C

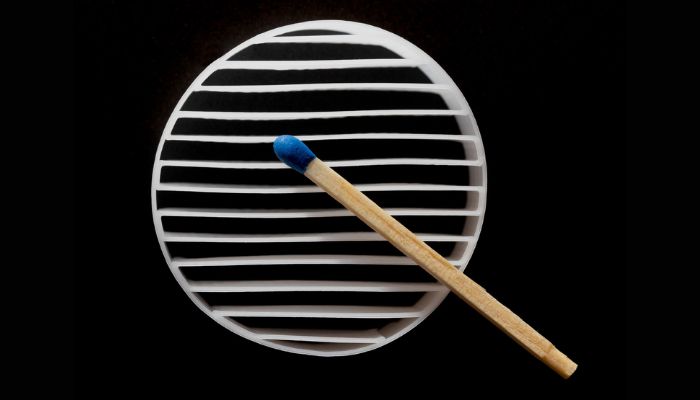

These toolheads deliver high-resolution prints, with line widths between 100–150 µm. For single-component applications, the print heads have a maximum volume flow of 6 ml/min, while two-component applications reach 12 ml/min, supporting both precision and efficiency.

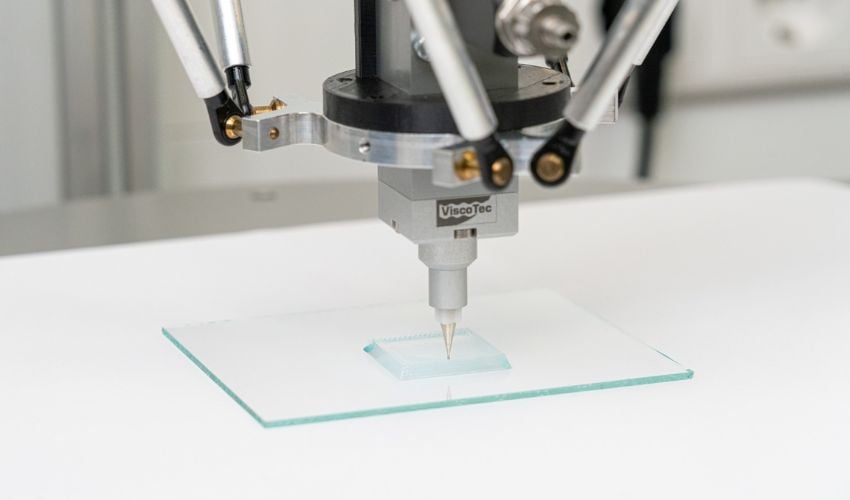

3D printing of fine lines from polycaprolactone

Expanding the Possibilities

With these capabilities in place, the vipro-HEAD medical series can now be applied to a wide range of patient-specific solutions. For instance, they can process key medical materials such as hydrogels, silicones, polycaprolactones, and ceramics. This opens the door to highly specialized applications, including patient-specific implants, prototypes, and innovative therapy solutions, even with a batch size of one. Some typical applications include:

- (Absorbable) implants, e.g., bone or breast implants

- Flexible implants such as silicone vascular structures

- 3D printed tablets for individualized drug release

- Wearables and prototyping for medical devices

One company that has used the vipro-HEAD successfully is 3Deus Dynamics, based in Lyon, France. Their team produces highly realistic anatomical models, like aortas, for surgical training and surgical planning. These 3D printed structures are also used in medical device testing. By using 3D printed models, medical practitioners and researchers can reduce their reliance on animal testing and cadavers.

Another Lyon-based company, Healshape, uses the vipro-HEADs to manufacture hydrogel-based, resorbable breast implants that are customized for each patient and regenerate after implantation through the body’s own tissue. Thanks to the combination of 3D printing, patented, biocompatible hydrogel, and precise print head technology, individual, natural breast implants are created that are resorbed by the body within a few months.

On the left, visualized representation of vipro-HEAD medical grade in 3D printing of an aorta made of silicone (Image source: ViscoTec), and on the right Hydrogel-based, resorbable breast implants manufactured using ViscoTec 3D print heads. (Image source: Healshape)

Johanna Bruckhuber, Business Development Manager of Components & Devices at ViscoTec, emphasized the importance of this development: “With the medical grade series of our vipro-HEAD printheads, we are taking the next step towards additive manufacturing in medical technology. This enables our customers to implement patient-specific solutions – from implants to individualized medicines – and thus makes an important contribution to the medicine of the future.”

With precision and reliability at their core, ViscoTec’s medical-grade vipro-HEAD printheads are making patient-specific solutions a practical reality, helping additive manufacturing play a valuable role in modern healthcare. To learn more about the vipro-HEAD medical series, click HERE.

What do you think of the vipro-HEAD medical series? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Cover Image: 3D printing of a silicone pyramid. All image credits: ViscoTec