A New Technology Can Create 3D Models Using Sound

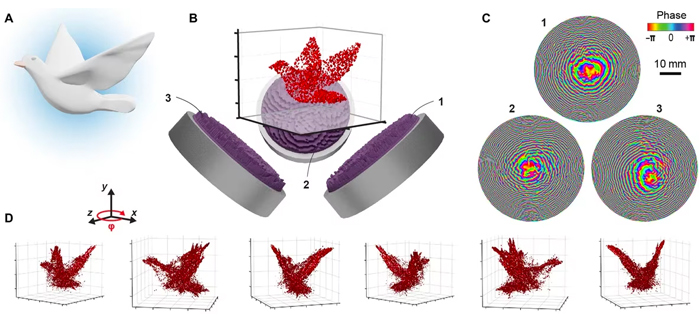

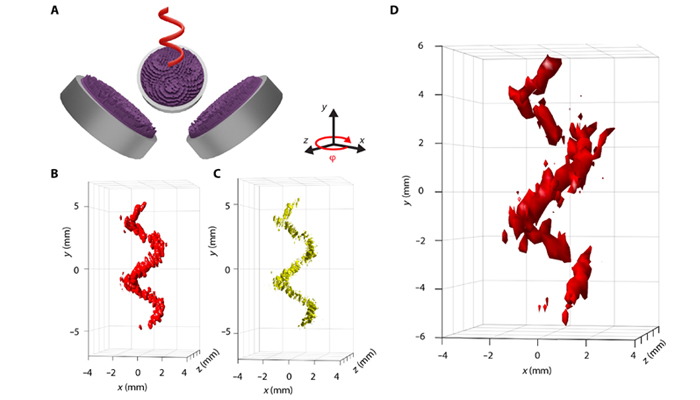

Additive manufacturing can be used in a wide range of fields and applications. Bioprinting in particular has shown real promise in the medical field. In this process, cellular structures are produced from a bio-ink to create skin, tissue and organs. To advance this field, a new project has emerged, led by scientists from the Max Planck Institute for Medical Research and the Institute for Molecular Systems Engineering and Advanced Materials at the University of Heidelberg, Germany. The research team has created a new technology to assemble 3D matter using sound. Its concept uses multiple acoustic holograms to model objects in three dimensions.

According to a study by Research and Markets, the bioprinting market will reach $5.3 trillion by 2030. This expansion is due in part to the growing number of chronic diseases worldwide that require innovative solutions. In the US alone, 105,800 people are on the national transplant list according to the Health Resources and Services Administration (HRSA) with a new person being added every 10 minutes. However, demand exceeds the supply, which is why there is an urgent need to develop new applications. Now, a further step could be taken in bioprinting with the new technology that combines sound and 3D printing.

Photo Credits: Max Planck Institute / University of Heidelberg

Characteristics of the 3D Technology

The project began when researchers first investigated how to form ultrasound using acoustic holograms. It was shown that these used sound fields could create 2D shapes. Then to make the method possible, the team developed a technology in which sound waves exert a force on the material, shaping the object. This is done using high frequency ultrasound, which cannot be perceived by the human ear. In addition, the wavelengths of the generated waves push below a millimeter, making it an ideal technique for manipulating a wide variety of materials, including biological cells and glass.

Kai Melde, the study’s lead author, explained, “We were able to assemble microparticles into a three-dimensional object within a single shot using shaped ultrasound.” His colleague Peer Fischer, Professor at the University of Heidelberg, further added, “This can be very useful for bioprinting. The cells used there are particularly sensitive to the environment during the process.” For the researchers, the study represents an important contribution to biomedicine. With ultrasound, cells can be worked on carefully and at the same time thoroughly, without damaging them, which is a really promising advance in this field. You can get more information about the study HERE.

Photo Credits: Max Planck Institute / University of Heidelberg

What do you think of the new sound-based 3D technology? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.