A New 3D Printing Material for Construction Could Be Capable of Capturing CO₂

Oregon State University and Sandia National Laboratory have received a three-year, $540,000 grant from the U.S. Department of Energy to explore whether it would be possible to capture carbon dioxide from industrial emissions before trapping its mineralized form in 3D printed construction materials. The researchers’ goal is to green an important sector of the economy, construction, which is one of the highest polluting. The study will be conducted by a team led by Pavan Akula, assistant professor of civil engineering at the OSU College of Engineering, and composed of researchers from Sandia, the Indian Institute of Science, the Indian Institute of Technology Roorkee, and the two industrial partners, Graymont and Verdant Building Alternatives.

In recent years, the issue of global warming and the need to take measures to decrease global warming and protect the environment have been increasing. The construction industry alone is responsible for generating 13% of global CO₂ emissions. 3D printing is seen as a possible solution to the problem, and already we have seen a number of 3D printing projects with concrete over the years. Yet, according to the researchers who initiated this study, the problem could actually lie in the very material used. “In recent years, 3D-printing technology for concrete has been gaining popularity in building construction as it is a more sustainable alternative – it reduces both waste and transport costs. However, most 3D printing of concrete still relies only on traditional materials that are really carbon intensive,” commented Professor Pavan Akula.

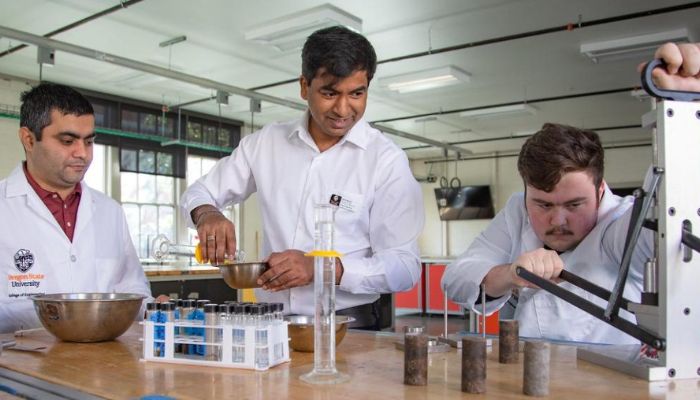

Photo Credits: Oregon State University

Or more specifically, he is speaking about Portland cement, which was developed in England in the early 1800s. Currently, it is the most common type of binder used in concrete. It is usually produced by mining, grinding and heating clay and limestone in industrial kilns at temperatures up to 2,820 degrees Fahrenheit. The process alters the chemistry of the materials and creates “clinker,” the main component of cement. However, this process also generates large amounts of carbon dioxide. This is what the researchers are hoping to address.

New 3D Printing Material Could Lead to More Sustainable Construction

How then can 3D printing intervene in solving this issue? The project aims to capture the CO₂ which is emitted by the lime and cement industries and develop sustainable binders that can store and mineralize the carbon dioxide captured in printed building components such as walls. “Our project aims to develop technologies and materials that can significantly reduce the carbon footprint of materials used in 3D printing,” Akula said.

Portland cement is widely used in construction despite its release of carbon dioxide (photo credits: KVDP, Public domain, via Wikimedia Commons)

The issue is particularly important as the demand for concrete is expected to continue to grow, as is the trend toward urbanization globally. Therefore, the use of new technologies is essential to address the problems of the present, just as new materials and ways of doing things are and will be needed in the future to address an ever-changing world. These new solutions may make it possible to achieve the goals set out in the Treaty of Paris. Signed in 2015, the international treaty entered into by the member states of the United Nations Framework Convention on Climate Change calls for containing the increase in global average temperature below the threshold of 2 °C above pre-industrial levels, and limiting this increase to 1.5 °C, as this would substantially reduce the risks and effects of climate change.

This is not the only project underway with this goal, we have repeatedly covered the issue of sustainability in additive manufacturing and innovative projects that contribute through the use of 3D technologies to protect the environment. In construction, for example, we have already seen clay or materials of biological origin to being used as a way to provide more sustainable housing. Moreover, we have seen recent initiatives such as the European project ConstructAdd, which studies the benefits of adopting metal as a 3D printing material in the construction and automotive sectors. You can find out more about the Professor Akula’s work in the press release HERE.

What do you think about the use of new 3D printing materials for construction? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: COBOD