A 3D Printed Microscope Made in Under Three Hours

At the University of Strathclyde, in Glasgow, Scotland, a team of scientists has embarked on a crazy challenge to produce their own equipment at an unbeatable cost – less than £50 or around $63. This microscope has a body that was entirely 3D printed, as were the lenses, using an SLA machine and transparent resin. A project that could well transform access to a diagnostic tool that remains very expensive today. But is its quality up to scratch? What can we expect from this kind of 3D printed equipment?

In the medical sector, additive manufacturing is widely used to design custom-made prostheses, anatomical models in preparation for surgery, implants, cutting guides and tools of all kinds. However, it is still rare to see diagnostic equipment made using 3D printing. Although this is not the world’s first 3D-printed microscope, it is probably the first such large-scale tool designed specifically for medical analysis. Researchers at the Scottish university downloaded a publicly available model from OpenFlexure. They added a camera, a light source and a Raspberry Pi.

The OpenFlexure website includes several microscope models (photo credits: Flickr / OpenFlexure)

The 3D-printed microscope uses a single lens, with a magnification of 2.9x and a numerical aperture of 0.07. That’s not very high for a microscope, but its resolution is good enough to perform reliable diagnostics at low cost.

How to Make a 3D Printed Microscope

The first step was to 3D print the microscope frame. The researchers chose the v6 model on OpenFlexure and then loaded the STL files onto the Bambu Studio slicer. They opted for black PLA, a layer thickness of 0.2 mm and a fill density of 15%. A Bambu Lab X1C printed the various frame parts in 10 hours, using just over 260 grams of filament. The researchers then proceeded to assemble the various parts of the microscope.

The condenser lens was redesigned on Fusion 360 from a commercially available lens. Once the STL file was ready, it was imported into LycheeSlicer and printed on the Elegoo Mars 3 Pro resin machine, using Formlabs resin. The layer height was set at 10 microns, with an exposure setting of 9 seconds. On the post-processing side, it took 9 minutes to clean the part and 15 minutes to cure in a suitable machine.

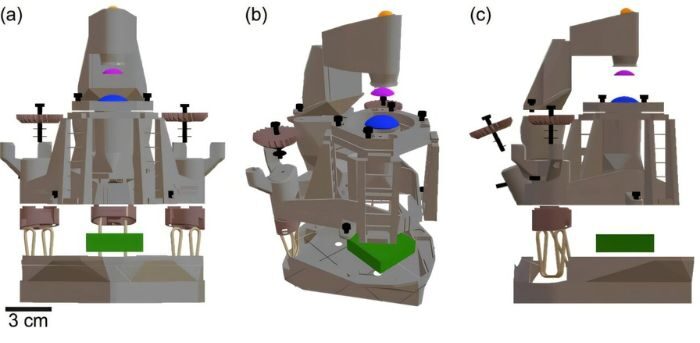

Front (a), oblique (b) and side (c) views of the microscope

Finally, the microscope’s objective lens was also redesigned for 3D printing. The objective lens was designed on a Mars 2 machine from ELEGOO, also using Formlabs resin. The same post-processing steps were applied.

The Results

After the assembly stages, several tests were carried out to measure the effectiveness of the 3D-printed microscope. The researchers explained, “To benchmark the imaging performance of the system, we used standard test targets and histological specimens, namely, a Giemsa-stained blood smear sample and a thin section of mouse kidney stained with Haemotoxylin and Eosin. We demonstrated that sub-cellular resolution was obtained, and we corroborated this by imaging individual red blood cells and intricate anatomical details of the stained mouse kidney section.”

The results obtained are satisfactory, and show that the creation of 3D-printed lenses can drastically reduce the cost of a microscope, enabling laboratories with more modest budgets, as well as schools, to equip themselves. Dr. Liam Rooney, a postdoctoral research associated who created the device, concluded, “This opens the doors to democratized access, rapid prototyping, and bespoke design of microscopes and optics at a fraction of the price of traditional microscopes. It could help scientists and medics in low-income countries around the world, as well as enabling students to learn more about science through accessible, cheap kit.”

There are still improvements to be made to the device, but initial analyses are promising! Would you like to find out more about this 3D-printed microscope? Read the full study HERE.

What do you think of this 3D printed microscope? Can it advance medical research? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! If you are looking for more 3D printing in medical & dental content, check out our dedicated page HERE. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Dr Liam M. Rooney / University of Strathclyde

A good start, comparable to the first compound microscopes of the 1600s. Higher magnification needs improved lens manufacture. A variation of a jeweller’s lathe perhaps, driven by stepper motors, to polish the 3D printed lenses?

Edit: found a 3D printed lens gri der, on YouTube.

https://youtu.be/_i-64P2WaDw?si=uRE2BEKaQysr4hI8