A 3D Printed Aerospike Nozzle Rocket Engine Ready to Take Flight

Spanish startup Pangea Aerospace and the company Aenium have signed a partnership to develop and industrialize advanced 3D printed combustion devices made from innovative materials. Together, they have designed a 3D printed aerospike nozzle rocket engine that should be 15% more efficient than those traditionally produced. The two partners intend to accelerate the development of their solution and continue their research on 3D printing materials, particularly superalloys.

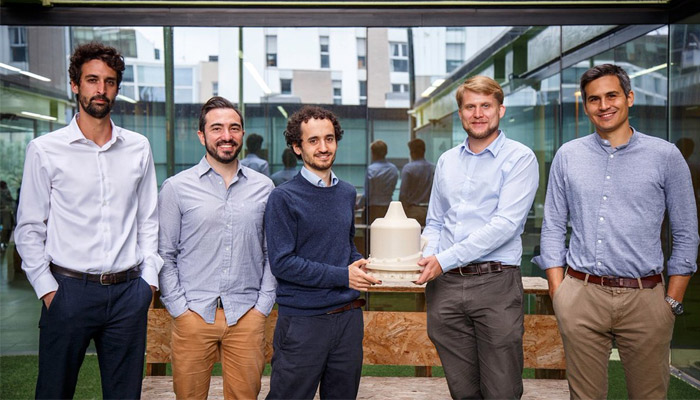

Pangea Aerospace is a young company based in Barcelona that aims to develop more efficient and modern rocket engines to meet the needs of the aerospace industry. After raising 3 million euros, it has formalized its partnership with Aenium, an engineering company specializing in additive manufacturing technologies and complex materials science. The goal is to advance the entire manufacturing process around advanced combustion devices, using 3D printing answering questions like: how can you qualify 3D printed parts? How to industrialize them?

Pangea Aerospace teams have raised 3 million euros

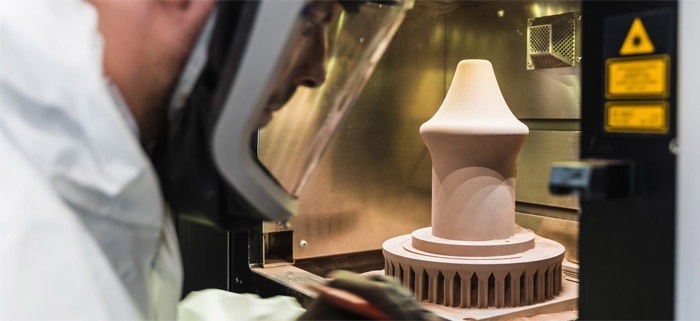

A 3D printed aerospike engine

Pangea Aerospace has produced a preliminary 3D printed aerospike demonstrator with the objective of a hot combustion test by the end of 2021. Called DemoP, it is a liquid oxygen and methane demonstrator that should allow for the characterization of several materials and processes (such as the use of 3D printing or methane as a fuel), a crucial point in the aerospace sector. Aenium is developing a dual regenerative cooling system. Both partners claim that this aerospike engine is 15% more efficient, faster to produce and less expensive. This is good news for the aerospace industry, which until now has not flown aerospike engines because of the difficulty of cooling this type of nozzle.

This additive manufacturing work will also make it possible to introduce to the European market a copper-chromium-niobium alloy developed by NASA: GRCop-42. Designed for laser powder bed fusion, it is a material that would offer high conductivity and high strength, ideal for high heat flow applications. Adrià Argemi, CEO of Pangea Aerospace, added: “The agreement with Aenium goes beyond shared exclusive capabilities on GRCop42 in Europe, a copper material specifically developed for rocket engines – Aenium also brings an unmatched expertise and R&D capability in processes and materials. GRCop42 based alloys are one of the key solutions that allow us to solve the thermal challenges of an aerospike nozzle rocket engines. We are now ready to offer this unique capability to all the European aerospace sector.”

Photo Credits: Pangea Aerospace

Pangea Aerospace is currently working on a larger engine, with the goal of commercialization in the near future. Miguel Ampudia, Aenium’s CIO, concludes, “This alliance will propel the next generation of reusable rocket engines also bringing the opportunity to the EU market to improve their combustion devices with the most innovative material science and qualified industrial additive manufacturing.” You can find the official press release HERE.

What do you think about this 3D Printed Aerospike Engine? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!