3D Printing Applications in the Fight Against Breast Cancer

According to the World Health Organization (WHO), in 2020, 2.3 million women worldwide were diagnosed with breast cancer, and 685,000 died from the disease. These figures make it one of the most prevalent and one of the leading causes of cancer deaths in women worldwide. It should be noted that men also suffer from this type of cancer. In fact, approximately 0.5% to 1% of breast cancer cases affect men as well. As for treatment, it is estimated that 40% require a mastectomy, the partial or total removal of the breast for recovery. However, only about 20% of these women choose breast reconstruction after removal, even though it is recommended by experts. In order to support the cause, the month of October has been designated as Breast Cancer Awareness Month, and more specifically, October 19 marks World Breast Cancer Day. In honor of that, we have compiled the different ways 3D printing can be used to help fight breast cancer and facilitate its treatment.

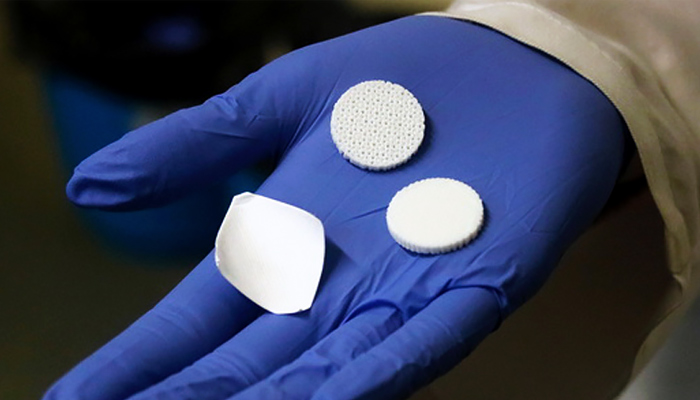

Collplant’s Plant-based Recombinant Human Collagen (rhCollagen)

With many of the traditional breast reconstruction procedures relying on a limited supply of human cadavers or animal tissue, CollPlant’s innovative 3D bioprinting approach removes this supply constraint, allowing for wider reconstruction access for more patients. Earlier this year, CollPlant and 3D Systems entered a co-development agreement to co-produce a 3D bioprinted soft tissue matrix product that is able to promote cell infiltration and proliferation by using bioink formulations based on rhCollagen. This tissue regeneration minimizes the risk of adverse immune response. Due to it’s plant-based origin, the rhCollagen also offers superior safety while meeting the mechanical requirements for implant procedures.

Photo Credits: 3D Systems

3D-Printed Drug-loaded Implant Breast Prosthesis

A team of scientists from several medical institutions in China, joined forces to conduct a study on localized chemotherapy breast cancer treatment. Traditional chemotherapy is delivered in massive doses, resulting in toxic side effects including hair loss, anemia, and nausea. Using 3D printing technology, the team of researchers designed a prosthesis containing the drugs paclitaxel (PTX) and doxorubicin (DOX) in order to prevent the recurrence of malignant tumors and metastasis following breast cancer-related surgery. The drug release showed that the 3D-printed prosthesis containing PTX and DOX microspheres was capable of releasing the drugs continuously for over 3 weeks, wherein suppressing a cancer recurrence threshold, and with significantly reduced side-effects. While the study was conducted on mice, this study revealed promising results for future development of breast cancer treatments in humans.

Photo Credits: Drew Hays/Unsplash

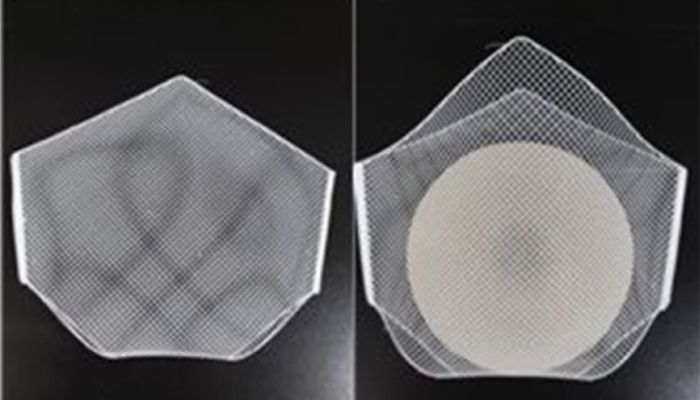

Lattice Medical’s MATTISSE Bioprosthesis

After 6 years’ research and 12 patents, Lille-based Lattice Medical has developed a breast bioprosthesis combining 3D printing, biomaterials and tissue engineering. Called MATTISSE, it consists of a 3D-printed shell that not only provides the desired volume and shape of the breast, but also fixes the tissue to be regenerated. The aim is to offer natural breast reconstruction in a single operation to all women in need. In concrete terms, the MATTISSE bioprosthesis is made from resorbable biomaterials that enable the regeneration of autologous adipose tissue; once implanted, the tissue regenerates for 6 months, and the prosthesis disappears naturally at the same time. Lattice Medical has thus equipped itself with a fleet of 3D printers – more specifically UltiMaker machines – located in a clean room and meeting the requirements of the medical sector. At the end of 2022, the French company is announcing the start of its clinical trials, with the aim of obtaining CE marking in order to begin marketing its bioprosthesis in Europe.

Healshape Is Using 3D Printing for Natural, Resorbable Breast Prosthetics

Isolation of aggressive cancer cells

A research group at the University of Girona succeeded in using 3D printing to isolate the cells that cause breast cancer in women. Specifically, they made tiny 3D matrices, called scaffolds, that reproduced the tissues and fibers of the human body. With the help of BCN3D Cura software and the Barcelona manufacturer’s Sigma 3D printer, they tested various parameters to create the most optimal models for the research. They made 10 copies of each configuration in order to see which geometry best separated the stem cells, which are the ones that cause relapses. By successfully isolating the stem cells of this subtype of cancer, the researchers will be able to study them better to find the biomarkers responsible for the tumors and be able to target them with drugs.

Photo Credits: University of Girona

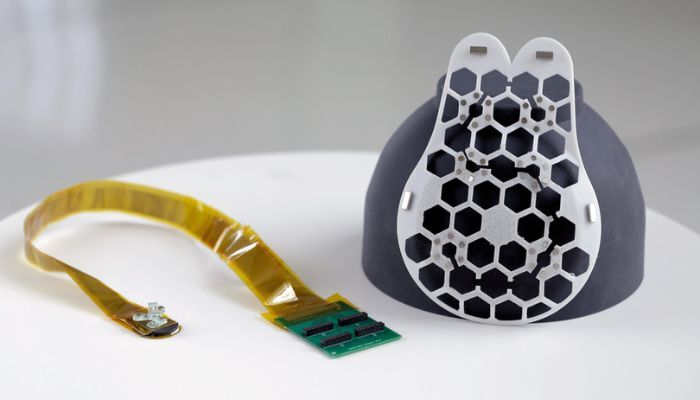

Fraunhofer IPT and BellaSeno – A Breast Implant with Autologous Tissues

Together with the Leipzig-based company BellaSeno, Fraunhofer IPT is working on the development of an automated production system that will in future manufacture breast implants from autologous tissue with a polymer structure. In the project, the companies are combining their expertise in 3D printing as well as knowledge in the fields of mechanics, electronics, measurement technology and software. The new method is expected to give hope to many women – because conventional implants often provoke a defensive reaction from the body and thus pose an additional health risk to patients. In the case of BellaSeno’s 3D-printed polycaprolactone implants, the implanted material is said to be completely degraded by the body within two years and the breast will once again consist of the body’s own cells. Thanks to the production facility, it should also be possible to manufacture the implants more efficiently and at a lower cost, which should enable more women to have surgery. However, it will be several years before the implants are approved. The two companies expect to have a first industrial prototype of the plant within the next few years.

Photo Credits: Fraunhofer

Plcoskin – TissueDerm

PLCOskin, a biotech startup from Korea, originated as an enterprise research center at Yonsei University. It specializes in soft tissue reconstruction with the development of TissueDerm™. TissueDerm™is a multi-purpose artificial dermis made from the combination of animal collagen and artificial polymer, which is 3D printed. In surgery, TissueDerm™ is used to reconstruct defective soft tissue, such as the breast of breast cancer patients. PLCOskin also offers other treatment options for these patients, such as breast prosthesis covers for breast reconstruction. Breast cancer is also the most common cancer among women in Korea, with an annual increase of 5%. However, about 80% of patients forgo breast reconstruction after mastectomy because of the cost and side effects. TissueDerm™is a safe artificial implant that is approximately 50% less expensive than other products on the market and also has no side effects. The material used has excellent biocompatibility and high tensile strength, so it does not cause inflammation in the patient’s body.

Photo credits: PLCOSkin / Invest Korea

The University of Limerick’s 3D-Printed, Bespoke Breast Prostheses

At the University of Limerick in Ireland, researchers have announced what they claim to be a ‘world first’: creating bespoke breast prostheses for women post-mastectomy using both 3D scanning and printing. Resulting from a collaboration between the Rapid Innovation Unit at the University of Limerick (UL), the Symptomatic Breast Care Unit at University Hospital Limerick (UHL) and the Mater Private Network’s Mid-Western Radiation Oncology Centre, the pilot service hopes to improve the quality of life for survivors of breast cancer. In essence, women who have undergone a complete mastectomy (full removal of one or two breasts) will have access to fully personalized prostheses that will be produced onsite at the point of care, perfectly matching the residual breast no matter shape or size. Though the researchers do not delve into which 3D printing technology was used, they do mention that the treatment hopes to address the lacking ‘one-size-fits-most’ approach that is the current standard. The project will aim to deliver tailored prosthesis solutions across Ireland.

The team behind the UL project (left to right): Emmajude Lyons, PhD Researcher, Rapid Innovation Unit, University of Limerick; Dr Lorraine Walsh, Consultant Radiation Oncologist, Mater Private Network Limerick; Mr. Chwanrow Baban, Consultant General and Oncoplastic Breast Surgeon, Symptomatic Breast Unit, University Hospital Limerick; and Dr Kevin J O’Sullivan, Senior Research Fellow, Rapid Innovation Unit (photo credits: University of Limerick)

Treating Cancer with the Help of 3D Printed Tumors

At the University of Waterloo in Ontario, Canada, A team of researchers are leading the fight against breast cancer with the help of 3D bioprinting. The team is revolutionizing the way that cancer treatments have traditionally been carried out in Canada and around the world. Previously, doctors would remove tumors via a biopsy, which could then be studied under a microscope in two dimensions. However, with the introduction of 3D bioprinting, doctors are able to model tumors layer by layer, comprehensively modeling like never before, and opening new avenues for faster and less expensive treatments, such as testing chemotherapy drugs and planning for the best treatment outcomes.

Photo credits: University of Waterloo

The 3D Printed Implant that Adapts to the Body and Releases Drugs

A group of researchers at Queen’s University Belfast (QUB), with the aim of treating breast cancer efficiently, have created 3D printed implants thanks to Tinkercad and the Cellink Bio X 3D bioprinter. These customized implants have been manufactured with intelligent materials capable of changing their shape and characteristics. Thanks to the use of this technology, the implants can be programmed, and controlled by external stimuli such as temperature or humidity, to improve their adaptation to each patient. The benefits of using 4D printing in the implant are not merely aesthetic, they are also capable of gradually releasing drugs in very precise locations. This type of chemotherapy drug (doxorubicin or DOX), helps the patient to prevent the recurrence of cancer cells.

Photo credits: Queen’s University Belfast

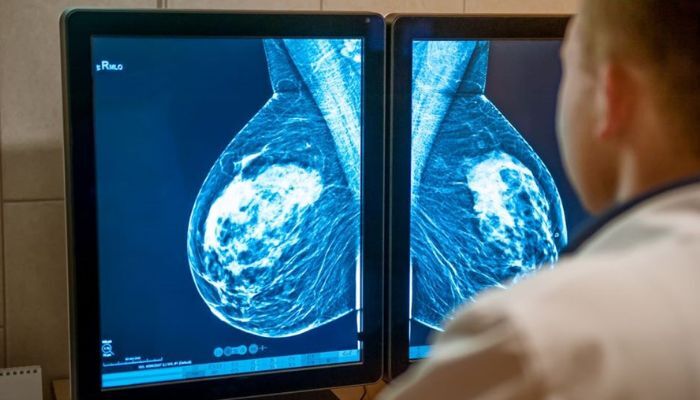

3D-Printed Ultrasound Device Designed to Fight Gap Cancers

A research team at MIT has created a 3D-printed device that promises to help in the fight against breast cancer. The purpose of this ultrasound device is to provide early detection of this type of cancer. Something that worries both doctors and patients is interval cancers. We are talking about tumors that develop rapidly between regular mammography appointments, which are also more aggressive than those detected routinely. Canan Dagdeviren, lead author of the study, points out that his aim was to design a device that would allow more frequent screening of high-risk individuals. The so-called cUSBr-Patch consists of a 3D printed patch with openings, which provides an in-depth scan and image from different angles of the breasts. This device was created using a 3D printer Prusa i3 MK3S+ using TPU and PLA, is attached to the bra and allows this type of scan from home in order to combat interval cancers.

Photo credits: MIT

3D Printed Scaffolds for Reconstructive Surgery

No matter the malady, reconstructive surgery is a way to allow patients to return to normalcy and feel more confident about themselves. Such is the case with researchers from Weill Cornell Medicine, who have used 3D printing to help improve the natural appearance of nipple reconstructive efforts for patients after undergoing mastectomies to treat breast cancer. The 3D printed disk is made of Poly-4-Hydroxybutyrate (P4HB), which is a polymer already used for surgical and medical devices. The customizable scaffold creates a mold-like shape which is eventually filled in by the body during its natural healing process after which, the P4HP breaks down. “This is an important step in helping patients who choose to have breast reconstruction after mastectomy feel whole again,” Explains professor of surgery, Dr. Jason Spector.

Photo credits: Spector Lab/Weill Cornell Medicine

Breast Cancer Tumor Model Clinical Testing Platform

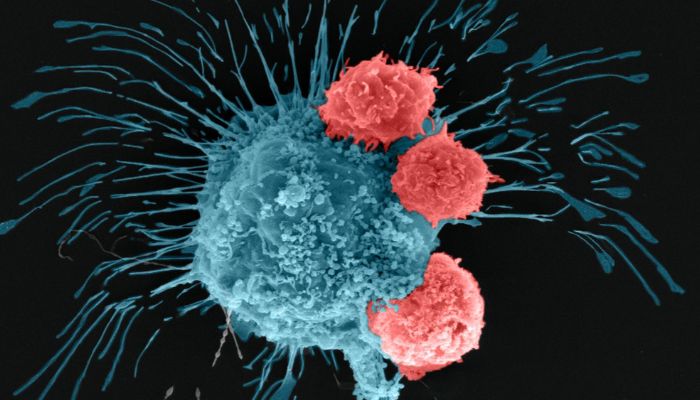

There are currently insufficient preclinical platforms for cancer drug research. A team of researchers at Pennsylvania State University therefore set out to use 3D-printed breast cancer models to explore the interaction between tumor cells, cancer drugs, and human immune cells. The results of the study were published in October 2022 in the medical journals Advanced Functional Materials and Biofabrication.

First, aspiration-assisted bioprinting was used to print a three-dimensional model of a breast cancer tumor, which was molded into a tumor model. Primarily, the research team tested how the tumor model responded to doxorubicin, a chemotherapeutic agent commonly used in the treatment of breast cancer. It was found that the tumor model responded to this chemotherapy. The researchers subsequently collaborated with an immunologist at The Jackson Laboratory to also explore the response of the 3D-printed tissue to human immune cells. The human CAR-T cells used for this purpose were genetically engineered to recognize and attack breast cancer cells. After just 72 hours, it was found that the CAR-T cells had triggered a positive immune response and were attacking cancer cells. Approaches such as that of the 3D-printed tumor model can help to evaluate and understand the response of therapeutic measures to tumor tissue.

Photo credits: Madhuri Dey, Ozbolat Lab / Penn State

ONEBra

ONEBra is a young Italian company that has devised a solution for women who have had to undergo a mastectomy following breast cancer. Often, in fact, the asymmetry of the breasts that results from this surgery causes additional psychological difficulties for patients. ONEBra has therefore devised customized 3D-printable bra cups that fit the woman’s physiology. Through scanning done at home, the client can scan her body and send the images to the company, which then 3D prints the customized bra cups and ships them to the patient’s home. Through the use of additive manufacturing, the product is shipped in a short time and with complete respect for the person’s privacy.

ONEBra 3D printed cups are made with HP MJF technology in TPU. (Photo credits: ONEBra)

What do you think of the applications for 3D printing in the fight against breast cancer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.