8 Reasons Why Multi-Material 3D Printing Is the Next Frontier

As 3D printing continues to mature, one development is standing out: the rise of multi-material printing. What was once a niche capability is quickly becoming a practical tool for engineers, designers, and manufacturers who want to build more functional parts in fewer steps. Multi-material printing is supported by several major additive technologies, including fused deposition modeling (FDM), stereolithography (SLA), material jetting, and more, making it increasingly accessible across industries. By allowing multiple materials to be combined in one build, it streamlines production, reduces reliance on assembly, and opens the door to more integrated designs. Here, we’ll dive into why multi-material printing is poised to become the next frontier in AM.

1. Growth of Multi-Material Printers

The most obvious indicator of the rise of multi-material printing is the proliferation of new multi-material machines. On the desktop side, Bambu Lab’s new H2C can print up to seven materials in a single run while generating minimal purge waste. Prusa has also entered the space with the INDX, an eight-material multi-tool upgrade for the Prusa CORE One that promises zero purge waste and faster tool changes.

Prusa and Bondtech developed a new multi-material printing system called INDX that introduces a tool-changing approach based on a single active “Smart Head” and multiple passive toolheads. (Photo Credit: Prusa)

Industrial systems are advancing just as quickly. Manufacturers such as OMNI3D and Rapid Fusion now offer large-format multi-material extrusion solutions designed for production environments. Beyond FDM, companies like Stratasys have long supported multi-material workflows through material jetting, while Aerosint (now part of Schaeffler) has demonstrated multi-metal laser powder bed fusion and binder jetting using its selective powder deposition technology. Together, these developments show how multi-material capability is becoming a more mainstream feature.

2. Improved Design Capabilities for Multi-Material Printers

As multi-material 3D printing hardware advances, software tools are evolving in tandem, giving designers unprecedented control over geometry and material distribution. Traditional CAD is being augmented by systems that support functionally graded materials. For instance, tools like GraMMaCAD allow users to embed graded material distributions directly into their CAD geometry, defining the material transition zones. This lets designers fine-tune where stiffness, flexibility, or conductivity lie. Meanwhile, OpenVCAD, an open-source, code-based tool, lets users merge two materials smoothly into each other.

Aero Mobius Drone Frame printed on a Bambu H2C (Photo Credit: Bambu Lab)

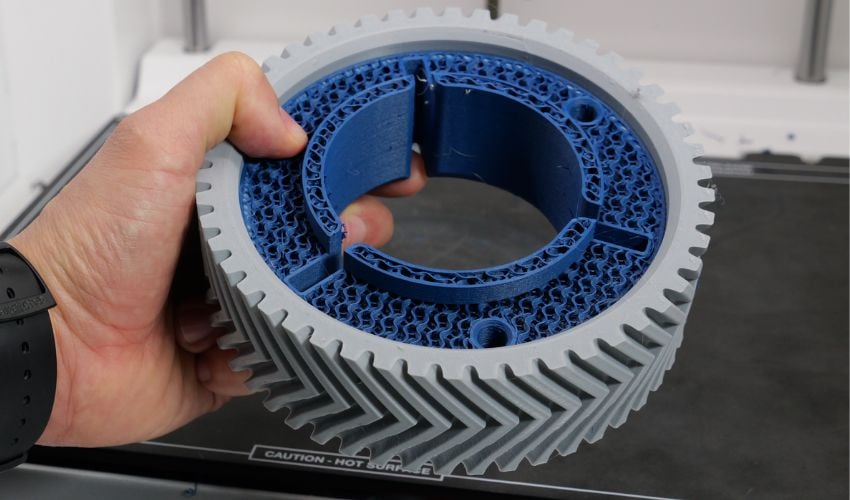

3. Combination of Distinct Material Properties

One of the most powerful advantages of multi-material 3D printing is the ability to merge different material characteristics into a single, unified part. Instead of manufacturing components separately and assembling them, designers can combine rigid, flexible, transparent, conductive, or high-temperature materials in one print, placing each material exactly where its properties matter most.

This capability enables far more functional and efficient designs. A single component might include rigid sections for structural strength, flexible zones for hinges, clear elements for inspection windows, conductive paths for embedded electronics, and heat-resistant regions for areas exposed to friction or elevated temperatures. By transitioning between these materials, multi-material printing makes it possible to optimize strength and functionality. Plus, it opens opportunities for advanced personalization: think of shoe insoles with softer zones, etc.

4. Simplifying the 3D Printing Process

Multi-material 3D printing can streamline the overall workflow. By consolidating multiple materials into a single machine, it simplifies material management and reduces the safety risks associated with handling and swapping materials manually. It also eliminates the need for extra hardware or add-ons typically required to print with several materials at once. Post-processing can become easier as well: users can rely on dedicated support materials like PVA or HIPS that dissolve cleanly without harming the part, reducing cleanup time and enabling more complex geometries than traditional breakaway supports allow. These advantages contribute to a faster, more efficient printing process.

Water-soluble support filament makes post-processing easier (Photo Credit: Airwolf 3D)

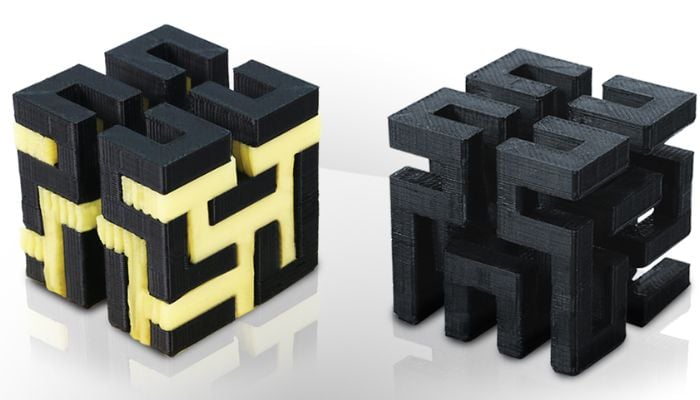

5. Reduced Assembly and Lower Production Costs

Multi-material 3D printing reduces the need for assembly by allowing multiple functional features to be created in one integrated part. With single-material printing, products often must be split into separate components that require additional fabrication, handling, and fastening. These steps increase labor and production costs. By producing rigid, flexible, and specialized regions in a single build, multi-material printing can reduce the need for fasteners, adhesives, and manual assembly. This cuts labor expenses and can ultimately lower the cost of manufacturing.

6. Enabling the Production of Realistic Prototypes

In addition to procedural benefits, multi-material 3D printing can enhance the visual appeal and tactile quality of parts, which allows for more realistic prototypes. Designers can produce components with multiple colors, textures, and surface finishes in a single build, reducing the need for painting or coating. This capability allows for prototypes that more closely resemble final products, as well as consumer-facing parts that are visually striking and ready for use straight from the printer. In the medical sector, this ability has been especially useful for anatomical models, where having multiple colors, textures, and opacities makes the model easier to understand. Essentially, by integrating aesthetic features directly into the print, manufacturers can streamline production while delivering more polished results.

Anatomical models can be used for advanced surgical education. (Photo Credit: Stratasys)

7. Advanced Printhead and Mixing Technologies

Building on the ability to work with multiple materials, recent advances in printhead and mixing technologies have improved both precision and reliability. Updated nozzles, dynamic mixing chambers, and automated tool-changing systems allow printers to deposit materials with extreme accuracy, smoothly transition between different material types, and reduce errors caused by misalignment or contamination. These innovations make it possible to produce complex, multi-material designs consistently and efficiently.

8. Broad Applicability Across Industries

Thanks to these advancements, multi-material printing is finding applications across a wide range of industries. From footwear and robotics to medical devices and consumer products, the ability to integrate multiple materials into a single component opens new design possibilities that were previously impractical or impossible. Companies can create parts that combine structural strength, flexibility, electronics integration, and aesthetic appeal all in one build, enabling innovative products while reducing development time and costs. This versatility makes multi-material printing a valuable tool not just for prototyping, but for full-scale production in diverse sectors.

Multi-material printing lets the footwear brand Footwearology print shoes with variable stiffness and cushioning. (Photo Credit: UltiMaker)

Do you think multi-material 3D printing is the next frontier? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credit: UltiMaker