8 Reasons to Use a Robotic Arm for 3D Printing

Robotic arms—motorized, programmable and designed for precision—have long been a staple of industrial automation. With joints and articulations mimicking a human arm, they enhance efficiency in manufacturing by streamlining repetitive tasks. Sound familiar? These advantages parallel those of additive manufacturing. So why not combine the two?

Integrating 3D printers with robotic arms introduces new opportunities, offering greater flexibility, adaptability and workflow optimization. In this article, we explore eight reasons to adopt robotic arm 3D printing. Note that while non-3D printing robotic arms can be used within an automated additive manufacturing process, in this article, we will focus primarily on robotic arms that directly perform 3D printing. There are many robotic arm 3D printing solutions on the market, so familiarize yourself with their benefits here!

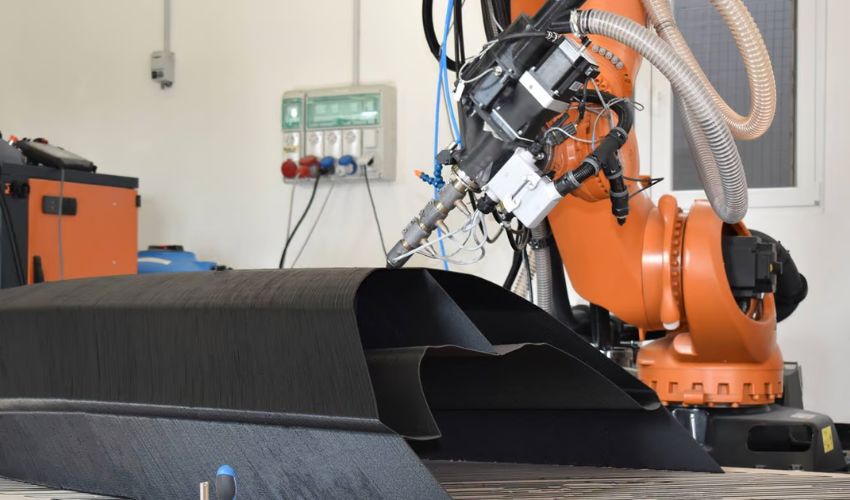

A robotic nonplanar 3D printer creating a curved pipe (Photo Credit: Emil Johansson)

1. Increased Flexibility and Multiplanar Toolpaths

Most 3D printers operate on the cartesian plane, a two-dimensional plane that is defined by the perpendicular x and y axes. Some robotic arms also are limited to a cartesian plane—but not all of them. Many robotic arm 3D printers can follow multiplanar toolpaths, printing not just on one flat plane, but in multiple directions. By not being restricted by traditional layer-by-layer, horizontal 3D printing, users are allowed greater design freedom.

2. Reduced Need for Support Structures

Because they can have multiplanar toolpaths, robotic arm 3D printers can also reduce the need for support structures. They are often capable of achieving significant overhangs, depending on the number of axes a robotic arm is working with, whether it be two, three, five or more. By minimizing the need for support structures, material waste and post-processing are reduced too, compounding the benefits of this technology.

3. Larger Build Volume

Robotic arm 3D printers do not necessarily need to be confined to a build plate or an enclosure. They can come in all different sizes to achieve a variety of build volumes, from desktop versions to big enough to construct buildings. Furthermore, robotic arm 3D printers can be mounted onto a track, making it mobile and able to print beyond the extent of its typical reach. This permits bigger projects and is great for aerospace and automotive solutions as well.

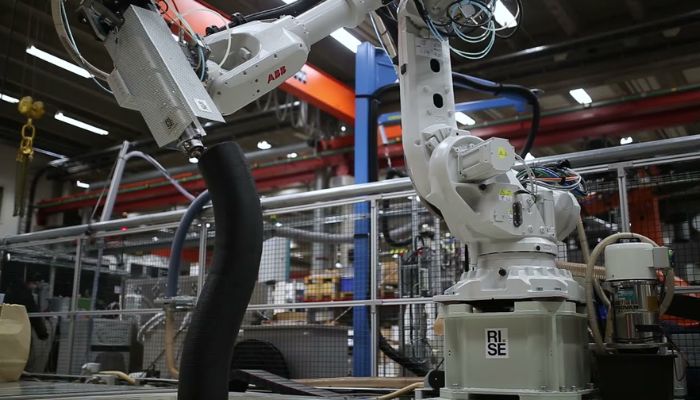

An example of large-format robotic arm 3D printing (Photo Credit: Replique)

4. Change Heads

A robotic arm 3D printer is no one-trick pony. These machines can have their heads replaced, enabling them to perform more than one function. Users can integrate different AM technologies, as well as non-AM technologies, into the workflow if the robotic arm is compatible with different tool heads. Here, even subtractive technologies like CNC machining can be achieved. This also opens up the potential for space optimization, as they can take the place of many different machines.

5. Repurpose a Robotic Arm You Already Own

If you already own a robotic arm and want to begin 3D printing, the good news is that it may be possible to adapt it. Adaxis, for instance, offers a software called AdaOne that transforms robotic arms into large-scale 3D printers. The tool supports a large range of hardware, deposition technologies and materials, making it compatible with a wide variety of applications. If your facility has a robotic arm that’s collecting dust, consider bringing it back to life through 3D printing.

6. Can Be a Comprehensive, Single-Cell Solution

There are also robotic arm 3D printing solutions on the market that are sold as comprehensive, single-cell solutions. Meltio’s Robot Cell is one that comes to mind. The metal 3D printing solution features a robotic arm enclosed in a cell, since the metal printing must occur in a controlled environment. The cell itself is compatible with other robot brands and operates with an ABB robotic arm as standard configuration. Because the design is compact, versatile and fully integrated, it reduces lead times and optimizes production.

A robotic arm solution from Massive Dimension (Photo Credit: Massive Dimension)

7. Can Print on Diverse Surfaces, Make Repairs

Robotic arm 3D printers can often print on diverse surfaces. This makes the technology highly effective for making repairs. Repairing equipment is a sustainable alternative to replacing parts and also reduces dependence on specific manufacturing tools. Sometimes, when parts are decades old or the company that created the part closed, it can be impossible to find the same part again. 3D printing with a robotic arm can facilitate a repair, making a part functional again that might not have been otherwise. Siemens Energy is just one company that has utilized wire arc manufacturing on a robotic arm to maintain and repair equipment like turbine blades.

8. Suitable for Variety of Materials and AM Technologies

Robotic arm additive manufacturing is compatible with multiple materials, from metal to plastics and concrete. It is also possible to use pellets for extrusion, widening the choice of material. Even fashion designers have used robotic 3D printers to fabricate designs, and textile designers have experimented with printing unusual materials like wool. Additionally, multiple AM technologies are compatible with a robotic arm, including but not limited to wire arc AM, wire laser AM, laser metal deposition, pellet extrusion, filament extrusion and concrete extrusion.

Would you use a robotic arm 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credit: KUKA