4D_Additive Now Includes Features to Repair 3D Files

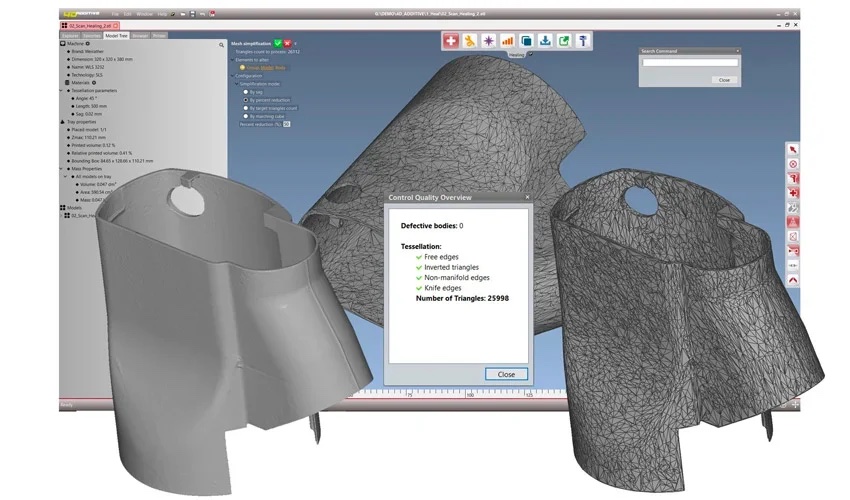

French-German company CoreTechnologie is adding new features to its CAD software, 4D_Additive, which is designed specifically for additive manufacturing. 4D_Additive 1.4, the latest version of the software, can now repair and simplify 3D scan data and STL files with a single click. Called Marching Cube, this new feature ensures error-free printing of the highest possible quality.

CoreTechnologie regularly improves its CAD software for additive manufacturing in order to offer its users an easy and efficient modeling experience. As we know, the design part in 3D printing is a key step in the value chain. Several design rules have to be taken into account, with a range of tools available to optimize the amount of material needed, the printing time, the part performance, etc. Among them are solutions for repairing the file and ensuring that the part will be printed without the slightest error. This is what 4D_Additive 1.4 offers.

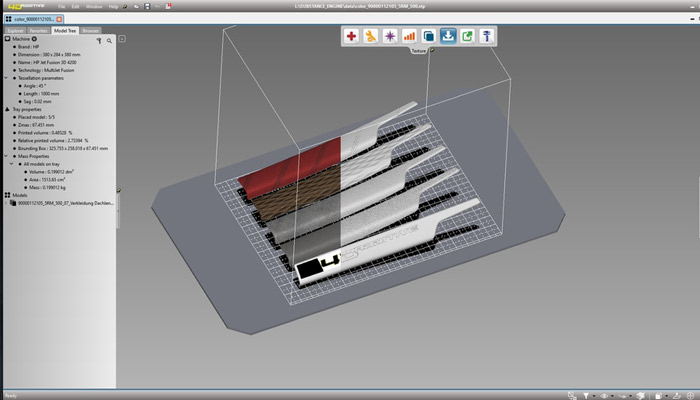

4D_Additive allows you to add textures to 3D files (photo credits: CoreTechnologie)

The New Version of 4D_Additive 1.4

In CoreTechnologies’ press release, they note: “The 4D_Additive 1.4 software has revolutionary functions to close the tessellated models into ‘watertight’ solids and intelligently mesh reduction functions in order to reduce the number of triangles without loosing accurracy. These new features called ‘Marching Cube’ and ‘Mesh Simplification’ allow any type of triangulated, mostly STL data, to be automatically corrected and simplified at the touch of a button.” By adding these two features, the company offers quick and easy repair without time-consuming manual intervention.

The CoreTechnologie team explains, “The Marching Cube function combines a “voxelisation” of the parts with their repair, whereby the size of the voxel, i.e. cube, and thus the fineness can be defined by the user. After the adaptive filling of the part volume with voxels, the so-called “voxilisation”, a closed 3D mesh is generated. The 4D_Additive software thus repairs models with hundreds and thousands of triangulation defects fully automatically within a few seconds. In addition, the user has access to various options for the intelligent reduction of triangles. By defining a maximum angle between the triangles, the maximum chord deviation, by percentage reduction or by defining the desired number of triangles the filesize and complexity of triangulated models can be reduced easily.” We can therefore expect a simpler and more reliable modeling process and a quicker preparation of 3D files. Feel free to watch the demo below and to visit CoreTechnologie’s website HERE to learn more:

What do you think of the new features in 4D_Additive 1.4? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.