How will 4D printing disrupt our current manufacturing techniques?

In April 2013, Skylar Tibbits, founder of the MIT Self-Assembly Lab, hosted a TEDx conference in which he introduced a new concept to the 3D printing process. For the first time, he introduced a fourth dimension to this technology that was already disrupting many sectors. He explained that 4D printing was like adding a new feature to a material that would be used for 3D printing, more precisely it was the material’s ability to transform over time. In fact, thanks to 4D printing, a material can change shape by itself, without any human intervention but simply over the influence of external factors such as light, heat, vibration, etc.

Since then, 4D printing has attracted the interest of many industries that see great potential for customizing devices and structures. According to the 2019 Gartner Report, interest in 4D printing is growing. By 2023, startups focusing on this technology should attract $300 million in venture capital. So inevitably, faced with this observation, we wonder what will the future of 4D printing be. Will it replace additive manufacturing for some applications? What will be its impact on the industry?

This 3D printed object gradually changes shape due to external factors. In other words it’s a 4D printed object | Credits: Self-Assembly Lab

How does 4D printing work?

4D printing is strongly inspired by the principle of self-assembly, which is not a new concept. You have probably heard of molecular self-assembly where molecules form complex structures without any human intervention. A concept widely used in nanotechnology as well for example. 4D printing therefore takes this principle to the next level. If it’s possible for small structures on a microscopic scale to assemble and move on their own, why not imagine it on larger 3D printed objects?

While 3D printing produces objects that keep their fixed shape, 4D printing will change their shape but also their color, size, the way they move, etc. It uses materials known as “intelligent” materials in the industry, which have been programmed to change shape under the influence of an external factor, most often temperature, just like when a computer obeys to code. This “code” is therefore added to the material and provides instructions to the 3D printed part. Bastien E. Rapp, President of the Process Technology Laboratory NeptunLab, explains: “4D printing is the functional form of 3D printing. Instead of printing only physical structures, we can now print functions. It’s like embedding a piece of code in a material – once triggered, it does what you programmed it to do.”

4D printing Materials and Technologies

4D printing materials are not as varied as additive manufacturing materials because the technology is still in its infancy but it is important to note that there exist different ones. Let’s start with shape-memory polymers (SMPs), which are materials that are able to store a macroscopic shape, preserve it for a certain time, and return to its original shape under the effect of heat, without any residual deformation whatsoever. Other indirect stimuli can also cause the transformation: a magnetic field, an electric field or immersion in water.

Another 4D printing material is liquid crystal elastomers (LCEs) which, as their name suggests, contain heat-sensitive liquid crystals. By controlling their orientation, it is possible to program the desired shape. Under the effect of temperature, the material will expand and transform according to the dictated code. The third material are hydrogels, these are polymer chains mainly composed of water, particularly used in photopolymerization processes. They are of great interest to the medical sector because of their biocompatibility.

Some 4D printing processes use multi-materials. It is mainly composites that are added to SMPs or hydrogels, such as carbon or wood fibers. The MIT Self-Assembly Lab began its research in 4D printing from a Stratasys Connex machine, based on the principle of material jetting, a multi-material process. Of course, there are other 4D printing materials, such as ceramics for example, but we have decided to focus on the main ones.

Credits: Self-Assembly Lab

Finally, the entire 4D printing process resides in the material. It is therefore necessary to understand how it will react to certain stimuli. Bastien E. Rapp explains that “a very good knowledge of materials is required to facilitate 4D printing.” Once this is well integrated, we can use different 3D printing technologies: stereolithography, material jetting (for all multi-materials), fused filament fabrication (working with polymers). Most often, the 3D printer used is an improved machine capable of taking account for the 4th dimension. Bastien E. Rapp continues: “Depending on the complexity of your 4th dimension, it can be as easy as printing two materials in parallel. This may also involve heating or cooling the material during the manufacturing process. There are many methods, all of which require specific conditions.”

4D Printing Applications

Since it is possible to program an intelligent material as desired, it can seem that the applications of 4D printing are quite extensive. Imagine an object that can take any form: technology can then impact the construction sector to build structures that are adaptable to climatic conditions, consumer goods could adjust to people’s needs, or even in the medical sector, etc. One of Skylar Tibbits’ first ideas was to use 4D printing to make intelligent pipes. These pipes would be able to change shape according to the volume of water they contain but also when any phenomenon occurred underground. This would avoid digging them up and changing them – a time-consuming and very costly process.

One of the sectors most interested in 4D printing is undoubtedly the medical sector. 4D printing could enable the creation of tailor-made, intelligent and scalable devices. For example, by 4D printing an implant, it would be easier to control its condition and viability once integrated by the patient. The same is true for all regenerative medicine and the manufacture of cellular structures. 4D printing could allow cells to adapt to a human body according to its temperature, for example. Chloé Devillard, who is currently preparing her thesis at 3d.FAB, explained to us: “We work with 4D printing for applications in tissue engineering and regenerative medicine in order to repair living organisms. In particular, I use it to reproduce a blood vessel that is as close as possible to reality in terms of physiology, function and mechanics. We can create constructions that are as similar as possible to living things.”

3d.Fab is currently working on 4D printing projects to create blood vessels | Credits: 3d.Fab

Finally, imagine a 4D printed drug printed that could release its substance depending on the patient’s body temperature. It is one of Dr. Fang’s research projects at MIT, he explains: “We want to use body temperature as a trigger. If we can design polymers correctly, we may be able to create a drug delivery device that will only release the drug if a fever develops.”

The transportation sector in the broad sense of the term is also interested in 4D printing, whether in the automotive or aerospace industries. In 2018, we told you about the inflatable material that had been developed by BMW and MIT, it canged shape and size under the effect of air pulses. An interesting material for designing future tires, for example, capable of self-repair in the event of a puncture or adapting to the most extreme weather conditions. Beyond cars, we can also talk about aircrafts. A 4D printed component could react to atmospheric pressure or temperature changes, and therefore change function – Airbus is currently working on this issue. The aerospace giant explains that these components could replace hinges, hydraulic actuators and thus considerably reduce the weight of these devices.

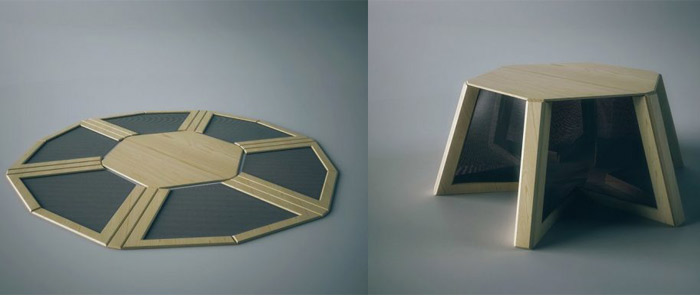

Imagine a stool that folds and unfolds by itself | Credits: Self-Assembly Lab

Finally, 4D printing is more than interesting for all applications that require a high degree of customization since it is possible to program the material according to our needs. At this stage the concept might seem strange but you could imagine clothes that take the real shape of our body, furniture that folds and unfolds to save space, etc.

The Future of 4D Printing

Although full of promise, this technology still has many limitations: what is the real resistance of intelligent materials over time? Will they still be able to carry out their duties in the long run? Many companies are still testing this manufacturing process and few have reported their results. Bastien E. Rapp told us that 4D printing involves a certain amount of very technical knowledge, which makes it more difficult to democratize it as much as additive manufacturing. “As this is a rather complex subject, requiring very good material and manufacturing control, it may not become as widely available and accessible as 3D printing itself. But it will nevertheless have a significant impact on the industry.”

BMW has 4D printed a silicone material that can inflate itself: is this the future of pneumatics?

What do you think of 4D printing? What will be the impact on our current manufacturing processes? Leave a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!

Realmente me facina las posibilidades de las 4D, recordé una anégdota que me sucedio en la entrega de un concurso en fines de los años 90, filosofando con un colega, fantaseabamos con los objetos que podian cambiar de forma para recostruirse, y pensabamos en los muebles inflables, otra forma de deconstruir las cosas, una suerte de pre historia de las 4D, existen muchos ejemplos de esto, sin ir mas lejos los juegos inflables de playa o el famoso sillon Lazy Bag.

I can see this technology used in art – a “painting” that has slowly moving parts, changing its appearance throughout the day.

Music – instruments that self tune as the temperature changes.

Hinges – less dependence on pneumatic cylinders.

Tools – parts that lock together then release at the push of a button using an electrical charge

A Great Article,

4D printing is a great innovation in the manufacturing process. After some research, 4d printing helps in all sectors. There is some application like a 4D printed valve,4D Printed shoes are playing a vital role.

4D printing will change the future of the manufacturing industry in the coming years. It has so many advantages as compared to other printing technologies. 4D printing is too much different than 3D & 5D printing. You have explained it very well. Please have a look at the relevant technologies for printing & mechanical engineering.

Wonderful blog with many helpful Informations. kindly visit