3i-PRINT project creates 3D printed front end on classic Caddy 1 car

Volkswagen is breaking into a full sprint with 3D printing following their recent project on 3D printing spare parts for their older modeled cars. In this latest development from the company, they are now working on a project alongside Altair, APWORKS, EOS, GmbH, csi entwicklungstechnik, GERG, and Heraeus in order to 3D print the entire hood of a Volkswagen Caddy 1.

This partnership was formed under 3i-PRINT, an engineering platform for research and development of innovative prototype concepts. It was under this platform that the group began their project on creating a completely 3D printed front end of the vehicle.

When choosing their vehicle model to work on, the choice of the VW Caddy 1 (a model that was produced between 1980 and 1990) was no coincidence, as the team wanted to demonstrate that 3D printing not only allows for further advancements in technology but also that it can adapt to pre-existing structures.

It is from this that the team built their objective to create a prototype of what could become the front structure of a car in the years to come. All members of the team were already aware of the potential that additive manufacturing is starting to have on the the automotive sector, with several projects that have already been launched amongst influential players such as Mercedes-Benz.

“We are proud to present the Caddy with an exemplary new additively manufactured front end structure,” said Stefan Herrmann of csi entwicklungstechnik. “The new structure and the contrast between old and new impressively demonstrates the potential that 3D printing and functional integration offer, particularly for the automotive industry.”

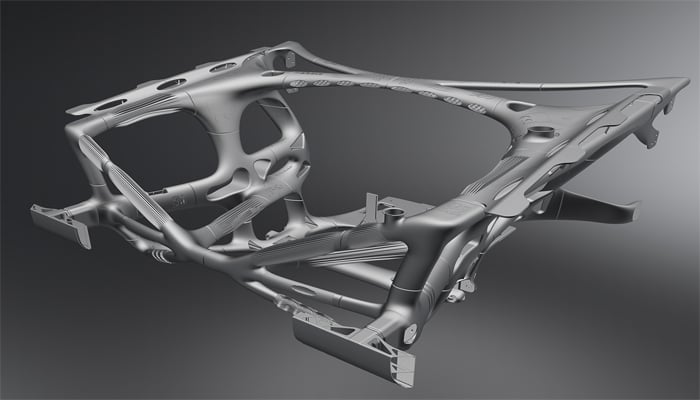

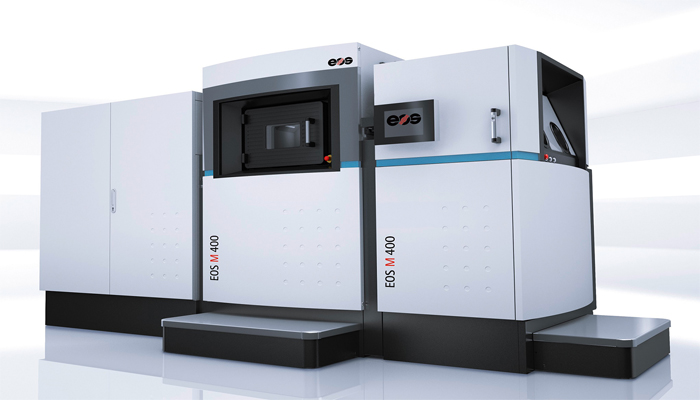

By combining their ideas, know-how, and the latest technologies available, the team was able to succeed in creating the first 3D-printed metal structure weighing only 75 lbs. Printed using a special alloy called Scalmalloy that was developed by APWORKS, their project ended with their final product of a functional front-end for the Caddy 1. While it may be hard to imagine so many companies coming together for one project, each were able to provide their specific knowledge for each specific aspect of its design- such as Altair’s work developing the applications to synthesize and optimize designs and processes and EOS providing the EOS M 400 3D printing system for APWORKS to use.

“I would…like to emphasize the agile, time-efficient route from the initial idea to the fully converted vehicle, which was completed within only nine months,” said Herrmann. “Each of the participating companies is a leader in its field. The outstanding collaboration and combined expertise has made the 3i-PRINT project a resounding success.”

The partially 3D printed Caddy will be on display at the Converge 2017 exhibition in Essen and the formnext 2017 show in Frankfurt.

Do you think that 3i-PRINT will be able to use 3D printing to bring our vehicles back to life? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!