#3DStartup: sallea Prints Edible Scaffolding for Cultured Meat and Fish Products

Our western eating habits, with meat and fish regularly on our plates, have far-reaching ecological consequences. Monocultures, overfishing and factory farming are just some of them. To counteract this, we have seen some innovative approaches in the last decade, such as cultured meat, increasingly from 3D printers. Cellular agriculture is an alternative to livestock farming and can reduce emissions by 90% compared to beef production. The trend towards this type of agriculture is increasing and the popularity of cultured meat and fish products is also growing steadily. Enter sallea, whose aim is to support producers of this type of food in their production. Founded in November 2023, the startup has developed innovative 3D-printed scaffolds that form the basis for cultivating meat and fish products of any shape and with a specific nutritional profile. In this way, sustainable products can be created without animal suffering. We spoke to Nicole Kleger, CTO and co-founder of sallea, to find out more about the startup’s beginnings, the innovative technology and its goals.

3DN: Could you introduce yourself and your connection to 3D printing?

My name is Nicole Kleger, and I am the co-founder and CTO of sallea, a spin-off of ETH Zurich. I originally studied materials science at ETH Zurich and then also completed a doctorate at ETH. At sallea, I am responsible for everything that has to do with technology. This includes the further development of our products, project management internally and with external collaborators, scouting for new technologies, IP strategy, as well as developing the strategy for sallea’s further technological milestones.

Dr. Nicole Kleger, CTO and co-founder of sallea (photo credits: sallea AG)

I came to 3D printing because I’ve always liked having tangible products in my research. In other words, something you can see with your eyes. I was therefore fascinated by 3D printing early on in my studies because not only can it quickly produce something tangible, but it can also produce very aesthetic products. During my studies, I also became aware of the outstanding technical advantages of 3D printing, provided it is used in the right setting. I was then able to carry out my first project work with Professor André Studart during my Master’s degree and was able to really ‘play’ with a 3D printer for the first time.

At the same time, as a materials scientist, I became increasingly aware that one of the biggest limitations of 3D printing is the limited choice of materials. Although this is constantly increasing, 3D printing is in a difficult position, especially in medical or food applications, which have very rigid approval procedures. So we were looking for a way to give non-printable materials access to complex 3D structures. Thus, the idea of an indirect process was born, using water-soluble, 3D-printed molds made from table salt. I carried out the first experiments in 2016 during my master’s thesis. Magnesium, a very reactive metal with great potential for medical applications, served as the model material. Together with my co-founder Simona Fehlmann, we built on this to develop the technology that now forms the heart of sallea.

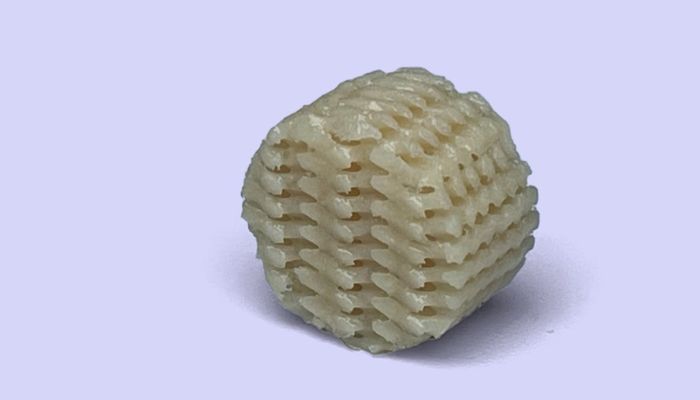

Protein sample used for cell tests (photo credits: sallea AG)

3DN: How did sallea come about and how do you use 3D printing?

During my doctoral thesis, I dealt in depth with the optimization of three-dimensional, highly porous lattice structures. I focused on their mechanical properties, optimized cell growth, but also on the development of new 3D printing methods for the production of such structures. In the last year of my doctoral thesis, Simona Fehlmann joined the research team and we continued to work on the innovative technology. At the end of my doctoral thesis, we had a great technology platform that opened up access to 3D printing for non-printable materials.

Since 2016, we have further modified and optimized the process so that we can now produce very delicate and complex structures from materials that could not be printed directly or only in very limited resolution. Today, we focus on applications in the food sector, or more precisely, we produce optimized scaffold structures from edible proteins and polysaccharides for cellular agriculture.

During an in-depth market analysis, we came across the hurdles that the production of cultured meat and fish currently faces. At the same time, we see huge potential in our technology to minimize these hurdles and drive cellular agriculture forward. So we decided not to let the technology simply disappear into a drawer, but to found sallea and thus create the greatest possible benefit for food safety and the environment. However, our founding team was still missing someone with the business drive. So Anna Bünter joined us and completed our power trio.

From left to right: Nicole Kleger, Anna Bünter, Simona Fehlmann (photo credits: sallea AG)

3DN: How does sallea’s printing process work and what materials are used?

Our printers only print common salt, the material used for our templates and stencils. We then cast the templates with a wide variety of materials that are difficult to print or can only be printed in low resolution. Finally, we dissolve the table salt and what remains is the cast material in the desired geometry. We mainly focus on edible materials for cellular agriculture. These include plant proteins and polysaccharides in particular.

However, the technology can also be used for many other materials.We have already molded thermoplastics (PCL, PS, PP etc), silicone, but also metals (aluminum, magnesium) in this way. With a few tricks, copper also works.

Nicole Kleger and Simona Fehlmann developed sallea’s technology together (photo credits: sallea AG)

3DN: What is the advantage of printing edible scaffolds and not printing meat cells directly as with other processes?

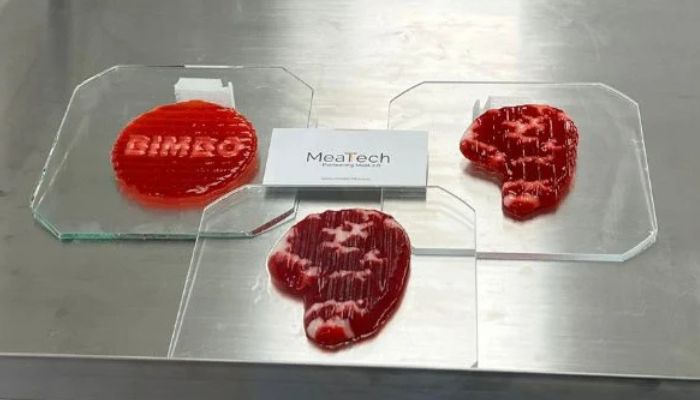

As mentioned above, many materials are difficult to print. This also applies to materials with cells. The direct printing of cells, also known as bioprinting, is mainly used academically. As the printability here depends primarily on the rheology, a wide variety of materials can be printed regardless of their chemistry – including cells. However, these rheological conditions pose an obstacle to the use of bioprinting for cultured meat.

In order to achieve a stable print, either printing must be done in a liquid bed or the printing ink must have a sufficiently high viscosity and elasticity to retain its shape after printing. This increases the shear forces during printing, which in turn has a negative effect on cell viability. To counteract this, the printing speed is reduced or the cell density is minimized, but this increases the costs.

Another challenge in bioprinting is the texture of the printed parts. At the moment, the proportion of cells in the end product is relatively low in order to keep costs under control. Accordingly, the matrix must contribute to the texture of the cultured product. In bioprinting, this often involves hydrogels, which are texturally more reminiscent of a jelly bear than a piece of meat.

3D-printed meat from cells grown by 3D bioprinting (photo credits: MeaTech/Steakholder Foods)

Overall, bioprinting certainly has great potential, but is currently still struggling with several difficulties. That is why we have focused on our indirect approach. We structure the edible scaffolds (known as scaffolds) using 3D-printed, water-soluble molds. This allows us to completely decouple the end material from the printing process.

3DN: What were your challenges as a team of women and what have been sallea’s biggest milestones?What are the next big goals?

As ETH graduates, Simona and I are used to being one of a few women among many men. Our third co-founder, Anna Bünter, is similar: she studied finance at the HSG. Unfortunately, it is a fact that the start-up ecosystem is still very male-dominated and as a woman, you probably feel less addressed to a certain extent. This probably discourages many women and many great ideas are lost. However, we ourselves have had almost exclusively positive experiences so far and would therefore like to encourage other women to take the plunge into this energetic, innovative and incredibly instructive ecosystem.

The three women leading the sallea team (photo credits: sallea AG)

We have already achieved important successes along the way. These include the MVP (minimum viable product) of edible scaffolds, the financing round of 2.6 M. USD in October 2024 and the expansion of an interdisciplinary team to six full-time employees. We have our MVP ready and are now in the first test phases with potential customers.

The next steps include the development of a final product with a customer who specializes in the cultivation of meat or fish. We are also working on integration technology so that the scaffolds can be integrated into our customers’ existing value chains as easily as possible. To this end, we will grow our team to around eleven FTEs by 2026 and welcome talents with training and experience in the fields of food science, biotechnology, materials science and business to sallea.

3DN: Do you have any last words on 3D printing in the food tech sector?

With the ever-increasing range of printers for manufacturing, the technology will also find its way into the food sector. However, as with all areas of application, it is important to carefully analyze in which cases 3D printing really offers an advantage. In the near future, we are unlikely to only consume 3D-printed food – because conventional production is still much cheaper and 3D printing does not bring any added value. However, in specific applications – be it for printed special foods for children, new taste experiences through specially combined foods, or new product categories – 3D printing will bring clear benefits to our food system. This is also the case in the field of cellular agriculture. If you would like to find out more about sallea, please visit our website HERE.

What do you think of sallea? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.