#3DStartup: Rosotics and the World’s Largest Metal 3D Printer

US-based startup Rosotics specializes in the development of 3D equipment, with a particular focus on metal additive manufacturing. Its goal? To offer manufacturers the largest metal 3D printer ever imagined on today’s market. Called the M1, this manufacturing platform offers impressive build volumes – ranging from two meters in diameter to 10 meters in height. It is capable of designing parts as imposing as fairings or tanks, meeting the requirements of sectors such as aerospace, maritime and energy. We spoke with its CEO, Christian LaRosa, to find out more about how this machine works and Rosotics’ ambitions.

3DN: Could you introduce yourself and Rosotics?

Hi, I’m Christian. I’m the CEO and Product Architect of Rosotics, a venture-backed industrial robotics and manufacturing R&D corporation developing and operating large-scale metal additive manufacturing systems for the production of massive structural hardware (such as the tanks, domes, fairings, and interstage of rockets). Our system, the M1, is deployed as the largest commercially available metal 3D printer in the world, serving in the aerospace, energy, and marine industries.

The Rosotics Team

3DN: Why did you decide to create Rosotics?

Rosotics was founded with the stated goal of enabling 3D printing’s usability as in heavy industry. Our industry, in small-scale, has advanced very rapidly in the past decade and has revolutionized how parts and components are manufactured. We believe that the large-scale segment as well must be able to access the capabilities of 3D printing, in the materials and performance thresholds it processes every day, and we developed a platform expressly to allow for that capability.

3DN: Could you tell us more about your manufacturing platform? What makes it unique?

Many companies in additive manufacturing have different definitions of the term ‘large-scale’. We are quite clear in ours, we do not use the word ‘parts’ here – we print ‘structures’, because the system operates at a very high mass flow rate to print very heavyweight hardware. Our platform, the M1, serves as the largest commercially available metal 3D printer in the world, printing from just 2 meters in diameter to well over 10 meters in height and diameter.

At the heart of our platform is an internally developed induction-based process; which does not utilize a laser of any kind, allowing for a significantly higher volumetric print speed as well as operating on far less of a footprint in terms of infrastructure and power demanded. The Rapid Induction Mass Extreme (RIME) approach also processes commercial-off-the-shelf (COTS) wire feedstock, removing the need for dangerous powderized metals, while maintaining the same level of aerospace-grade performance.

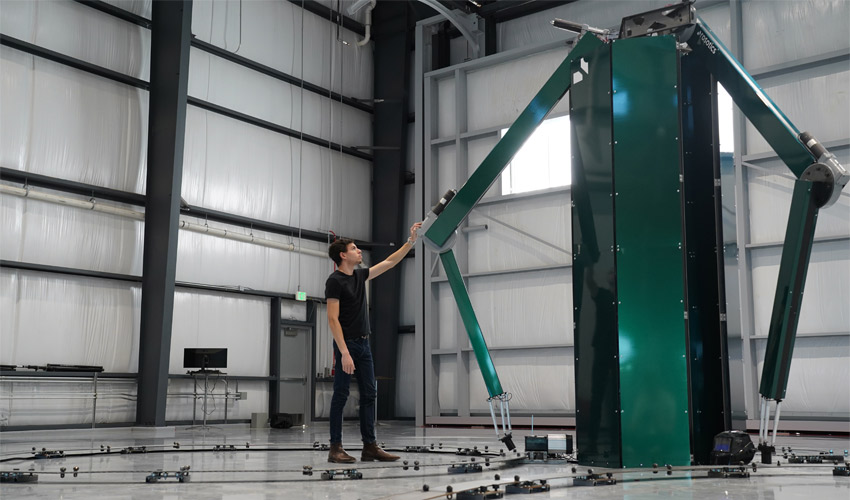

The M1 manufacturing platform

3DN: What sectors are you targeting?

M1 is designed to supply the capability to additively manufacture not only aerospace hardware, but that of wind turbines, marine vessels, or any sufficiently difficult metal structure that would traditionally be machined or forged. Our platform is qualified to serve most if not all primary structural production of these scales in one automated platform. This is a capability typically served of multiple independent tooling systems.

3DN: How do you see metal AM in the next 10 years?

Many consider 3D printing as an industry that had ‘peaked’ several years ago, when this is not the case. The benefit of 3D printing has not been realized yet; that is when you are able to accelerate what was traditionally 3–4 years of testing campaigns predicated on very long bespoke lead times, down to under a year. What this industry will allow, upon the emergence of accessible large-scale print capabilities, is a form of manufacturing optimization not seen since the days of Henry Ford and the first assembly line.

The M1 enables large-scale production

3DN: Any last words for our readers?

We value builders. If you strive to build, or are already working on a breakthrough product that could be accelerated from M1, we would love to be in touch. You can find out more about Rosotics HERE.

What do you think of the 3D printer developed by Rosotics? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Rosotics