#3DStartup: ONEBra Supports Women After Mastectomies With 3D Printed Custom Cups

Among the many benefits that additive manufacturing can bring is the ability to make customized products. In the medical sector, being able to have this advantage means being able to provide patients with personalized medical care and devices and bring a positive and concrete contribution to their lives. Indeed, the use of additive manufacturing makes it possible to obtain medical devices that are fit exactly to the person’s body. This is the case for the 3D startup chosen for July, ONEBra, a young Italian company that has decided to use 3D technologies to make life easier for women who have undergone mastectomies after breast cancer. How? By producing customized 3D printed bra cups! Sofia Santi, Founder and Materials Engineer, told us more.

3DN: Could you introduce yourself and tell us about your connection with 3D printing?

3DN: Could you introduce yourself and tell us about your connection with 3D printing?

I am Sofia Santi, Ph.D. in Materials Engineering, CEO of ONEBra, with 8 years of experience in biomaterials and additive manufacturing. ONEBra makes custom cups through 3D technology for women with breast asymmetry following breast cancer removal. In addition, we also offer a community service to support women and those close to them with all-around help.

3DN: How did ONEBra come about and what is its purpose?

Starting from a direct experience, which involved my mother undergoing mastectomy surgery, we wanted to pursue a project that would give voice to all those women who, due to natural causes or as a result of operations, have breast asymmetry. We address those women who perceive their asymmetry as a burden to live with by giving them the opportunity to feel free to express themselves again. During the development of the ONEBra project we became aware of many social and service gaps, which strengthened even more our motivation and determination to evolve the project into a startup.

3DN: How are ONEBra custom cups produced? What is the process you follow?

The process begins when the end customer visits our website (onebra.co.uk). From there it is necessary to download the Heges app to perform the 3D scan. The scanning process is then performed in total autonomy following our video training. Once the scan is done, via shared link, the scan data can be delivered directly to the ONEBra team.

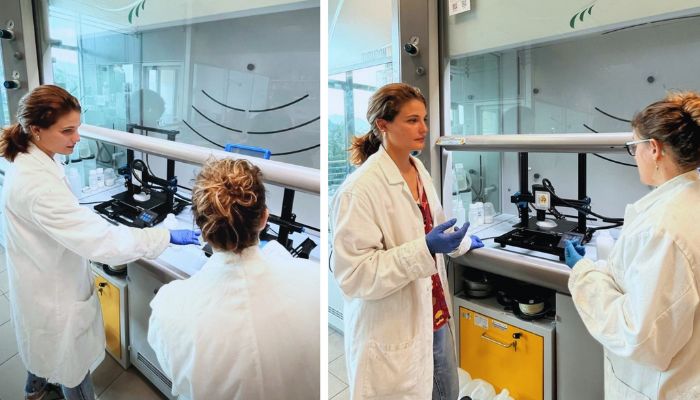

ONEBra processes the scan with a modeling program to create the custom cup. This is then printed in TPU/TPE with Multi Jet Fusion (MJF) 3D printing technology and for some parts of the cup with FDM technology. The cup is then coated with a material suitable for skin contact to make it more natural to the touch and comfortable and is finally inserted inside the chosen bra. The final product is shipped from ONEBra directly to the customer.

ONEBRa’s 3D printed cups

3DN: What are the biggest benefits that additive manufacturing brings to your business?

Zero waste, direct recycling of much of the printing material, high accuracy, available materials already certified for skin contact, and above all, the choice of MJF technology manages to sustain medium to high demand in a short time.

3DN: How do you see the continued role of 3D printing in healthcare?

3D printing helps to create working prototypes in a short time, in the medical field it is already used in surgeon training before surgery helping to decrease surgery time and achieve better results. In addition, the ability to customize prostheses to be placed in specific patient sites always decreases surgery time, which is good not only for the patient but also for the stress the surgeon is under. In addition, it is used to create devices for applications outside the body, such as orthotics. The customization provided by 3D printing can certainly help to have more targeted care.

ONEBra has several plans underway to launch new products on the market soon

3DN: What are the main difficulties you encounter in your work?

Standard pieces are produced faster and in a shorter time, while custom pieces have longer lead times. In terms of quality, fit and comfort, however, not comparable to the previous ones. In addition, we thought that the scanning process, which the woman does independently, was difficult for the client to perform, but we believed in their abilities and they were great at sharing their scans in a very short time. Moreover, in case of any kind of difficulties, we also provide a support service, which lengthens the delivery time a bit, but our priority is the quality of the product.

3DN: Any last words for our readers?

Next year we plan to launch our product for both sports bras and swimwear fashion. Follow the news that will soon be posted on our social media and on the ONEBra website HERE.

What do you think of ONEBra? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: ONEBra