#3DStartup: MB Therapeutics and its 3D Printed, Customizable Medication

In the field of personalized medicine, 3D printing is extending its scope beyond prostheses and implants to venture into an innovative field: medication. This technological advance opens up promising prospects for simplified treatments and personalized dosages tailored to patients’ unique profiles. Although this approach is still in its infancy, French startup MB-Therapeutics has taken the initiative to develop a solution.

Based at Montpellier’s Faculty of Pharmacy, MB-Therapeutics has unveiled its innovative process focused on the creation of personalized medicines using 3D printing. The fruit of eight years’ experience and research, the system, dubbed Med-U Modular, stands out for its patient-centric focus, initially dedicated to the needs of children. Founders Stéphane Roulon and Ian Soulairol aim to simplify the lives of young patients by exploiting the high degree of customization offered by 3D printing.

This technology enables MB-Therapeutics to design medicine with individually adapted dosages and shapes, combining several active ingredients within a single tablet. The ultimate goal is to overcome the constraints associated with taking multiple medications. We caught up with Stéphane Roulon, CEO and co-founder of MB Therapeutics, to find out more about these personalized medicines and the company’s future plans.

3DN: Could you introduce MB Therapeutics and tell us your connection with 3D printing?

MB Therapeutics is a start-up created from 8 years’ experience in the pharmaceutical industry, hospital pharmacy and academia on the subject of pharmaceutical 3D printing. At the heart of the pharmaceutical industry, where I’ve been since 2016 with a particular passion for pharmaceutical 3D printing, we were looking for a flexible way to catalyze the development of new drugs. This is where 3D printing proved to be our ideal ally, offering an innovative and effective approach.

In 2019, we began collaborating with Ian Soulairol, a hospital pharmacist. I discovered that there was no automatic process for producing personalized medicines, and that the solutions offered to children were not ideal. So, in order to address these issues and, more generally, offer personalized medicines to all patients, we created MB Therapeutics.

3DN: How did you come up with the idea of combining 3D printing and pharmaceuticals to create personalized medicines?

In 2016, when we started looking for flexible, adaptable processes, 3D printing came up. We started testing standard 3D printers to validate our concept, but realized that the materials available didn’t meet our specific needs. So we started developing pharmaceutical 3D printing. We then put this idea into practice with the MED-U Modular, our pharmaceutical 3D printer.

Stéphane Roulon (left) and Ian Soulairol (right)

3DN: How does MB Therapeutic’s MED-U modular 3D printer work?

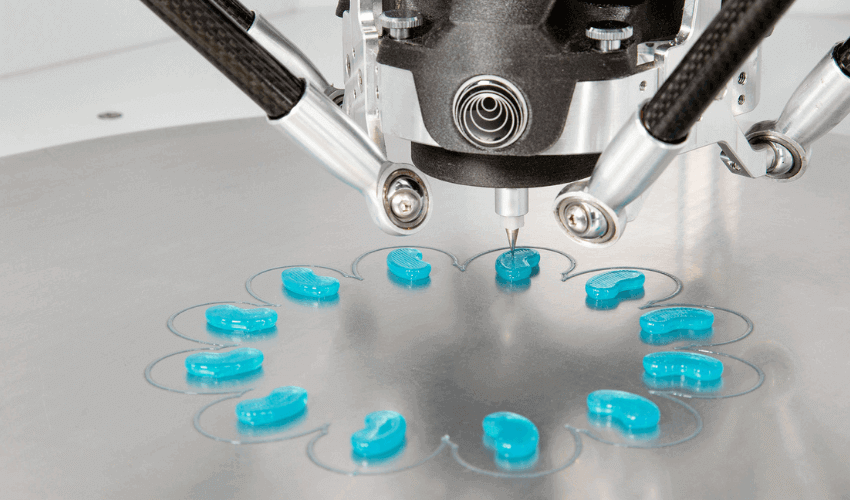

The MED-U Modular is the first industrial-grade pharmaceutical 3D printer. This printer is fully compliant with pharmaceutical standards, and comes with qualification files. The MED-U Modular already integrates 3 types of 3D printing technology, which can be quickly and easily interchanged. How it works is it incorporates gel/paste extrusion technology with volumetric dosing, ensuring optimum precision and reproducibility when depositing material.

At MB Therapeutics, we also offer fused modeling deposition (FDM) technology, specially adapted to the requirements of pharmaceutical filaments, known for their technicality, fragility or high flexibility. This has led us to develop a print head that can be dismantled quickly, while complying strictly with pharmaceutical standards. The integrated software meets all the requirements of the pharmaceutical industry, ensuring traceability, electronic signature, security, and seamless interconnection with other software depending on the needs of the healthcare players.

3DN: What are the advantages of using 3D printing technology for medical treatments, especially with sick children?

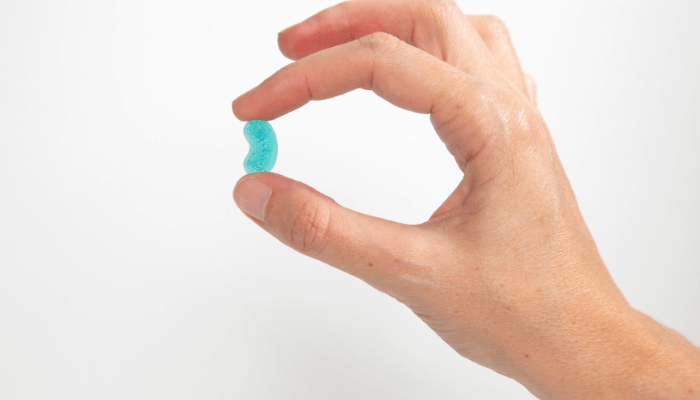

Currently, for certain illnesses, the pharmaceutical industry does not meet patients’ needs. For patients, especially children, capsules and tablets are impractical, as they carry the risk of choking or swallowing. What’s more, liquid suspensions, which may contain excipients (inert pharmaceutical ingredients) with known effects or be contraindicated for certain age groups, are less stable and run the risk of administration errors with dosing pipettes. We therefore offer a new solution enabling pharmacists to automatically produce medicines in personalized doses and forms, combining the advantages of tablets and liquid suspensions.

These new-generation medicines are suitable for children, as they can be dispersed in a very small volume of water. They are formulated without excipients with known effects, and reduce dose administration errors. We are the only company in France and worldwide to have an industrial-grade 3D printer that complies with pharmaceutical standards.

These 3D-manufactured drugs have a bean-like appearance

3DN: How does pharmaceutical 3D printing help reduce the risk of dosing errors?

When a capsule is opened to administer the contents to a child, the dose can vary by up to 30%. In the case of liquid suspensions, around 30% of parents make dosing errors at home. Customized medicines manufactured by 3D printing help to secure and reduce the risk of dosing errors by offering formulations that are dispersible in a very small volume of water or orodispersible.

This assures parents that they can administer the prescribed dose to their children with complete confidence. On the pharmacist’s side, the production of these drugs using 3D printing enables the process to be automated with industrial manufacturing quality, while preserving the flexibility of manual compounding.

3DN: What are the upcoming projects for MB Therapeutics?

Between 2023 and 2026, we aim to collaborate with all hospitals, universities and industrial establishments wishing to develop new solutions for their patients. This collaboration can be achieved with the MED-U Modular, our pharmaceutical 3D printer. In 2026, we will be launching a turnkey solution, from printer to pharmaceutical cartridge, for dispensing pharmacies and hospitals. This solution will enable the automated, personalized manufacture of medicines, initially targeting children.

3DN: Any last words for our readers?

Every person is unique! So why shouldn’t our medicines be? At MB Therapeutics, we’re convinced that all medicines will soon be available in personalized dosages. You can find out more HERE.

The startup has teamed up with Lynxter, experts in the development and manufacture of industrial 3D printers

What do you think of MB Therapeutics? Do you think personalized medicine is the future of healthcare? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Stéphane Roulon