#3DStartup: Lensy Medical Creates Personalized Contact Lenses With 3D Printing

3D printing continues to transform the medical sector, and its influence now extends to the ophthalmology sector, particularly in the manufacturing of lenses. This is the case of startup Lensy Medical, which manufactures contact lenses using 3D technologies. Its approach aims to offer customized lenses, optimizing comfort and adaptation, while paving the way for advances such as myopia control, controlled drug delivery, and the development of intelligent lenses. In fact, those behind the company envision a future where eye care goes far beyond simple vision correction.

The device, currently in the development phase, offers optometrists and eye care professionals greater autonomy by providing them with advanced tools and skills. This will enable them to diversify and specialize further, while helping to make eye care more accessible and inclusive for more patients. To find out more about this project, we went to meet Edan Kenining, founder of Lensy Medical.

Photo Credits: Lensy Medical

3DN: Could you introduce yourself and your connection with 3D printing?

My name is Edan Kenining and I’m the founder of Lensy Medical. Over 13 years ago, I acquired my first 3D printer and immediately saw its immense potential to revolutionize rapid prototyping. Over the course of my career, I have integrated 3D printing with microcontrollers in industrial environments, enabling me to dramatically improve efficiency while reducing costs. I’ve also used 3D printers extensively, even converting them for specialized tasks to meet unique challenges on various projects.

3DN: What is Lensy Medical and why did you decide to create this company?

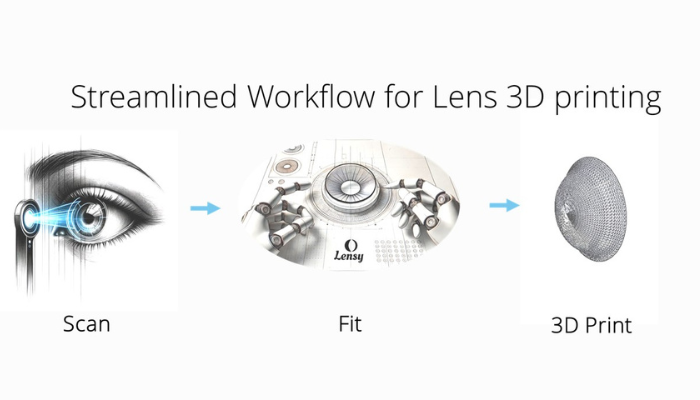

Lensy Medical is a proof-of-concept startup at the crossroads of ophthalmology and additive manufacturing. Our mission is to transform contact lens production by introducing a new manufacturing model: 3D printing directly at the point of care. Today, mass-produced lenses follow a standard “one size fits all” model, adapted to the average eye shape. Yet every year, millions of people experience discomfort that causes them to give up using lenses.

Custom lenses are expensive, require a lengthy fitting process and are mainly reserved for specific medical cases. With our 3D printing solution, we aim to make custom lenses more accessible and affordable by using eye scanners to create bespoke lenses directly in clinics.

3DN: What materials and technologies do you use?

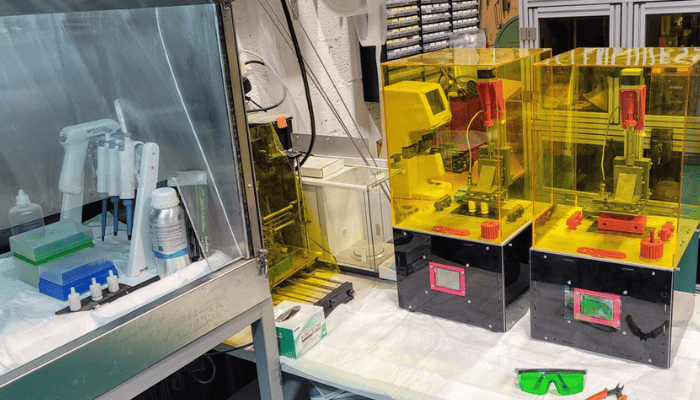

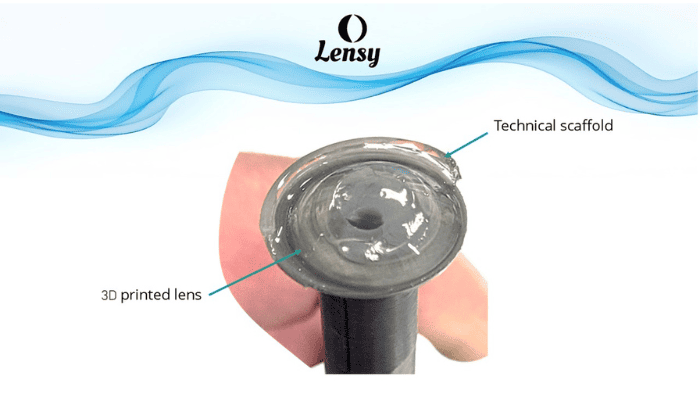

To our knowledge, we are the first to have successfully converted FDA-approved contact lens materials into 3D-printable resin, while controlling the printing parameters. We use vat photopolymerization, and our in-house printer has been designed to optimize Z-axis resolution for greater precision. We have also developed a method that uses a sterile capsule to minimize material waste, making the process more efficient and reducing the technical burden on clinicians. This means they can concentrate on patient care rather than complex machinery.

Photo Credits: Lensy Medical

3DN: What are the advantages of 3D printing for contact lenses?

We believe there is a technological opportunity to create a decentralized system for mass customization of contact lenses. This approach not only overcomes the limitations of scale associated with traditional 3D printing, but also accelerates the pace of innovation. By using the same system for prototyping and production, the time between design and commercialization is considerably reduced. This also opens the door to future innovations, such as lenses incorporating advanced functionalities like myopia control, drug delivery, or intelligent components.

3DN: What challenges do you face in integrating 3D printing into your production process?

While 3D printing is the basis of our concept, our main challenge is to forge partnerships within the contact lens and ophthalmology industries to help us scale up and transform the way contact lenses are fitted. We are actively seeking collaborations that can bring this vision to life.

Photo Credits: Lensy Medical

3DN: What does the future hold for 3D printing in the ocular field?

3D printing has a lot to offer in the wider ocular field, but I’ll focus on its application to contact lenses. A 3D printer dedicated to contact lenses is a versatile platform that can cater for a variety of applications in different environments.

For example, in optical stores, these machines could be used to manufacture vision correction lenses or myopia control lenses, which slow the progression of myopia in young adults. In pharmacies, they could produce lenses for drug delivery, while in hospitals, they could be used to design customized intraocular lenses. In the future, when smart contact lenses become commonplace, our technology will play a key role in enabling these lenses to be customized for optimum comfort.

3DN: Any last words for our readers?

In my opinion, 3D printing has been heralded as the catalyst for the next industrial revolution, but this promise has yet to be realized, as printers remain too generalist. I urge others to focus on developing 3D printers tailored to specific applications, rather than creating all-purpose machines. Only by specializing in specific uses can 3D printing truly replace traditional industrial processes.

Edan Kening, founder of Lensy Medical (photo credits: Lensy Medical)

What do you think of Lensy Medical? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Freepik