#3DStartup: HETEROMERGE and Multi-Material, Micro 3D Printing

Although additive manufacturing is an increasingly democratized production tool, we can still find certain limitations in adoption. For example, industry in particular is experiencing an increasing need for precision in end-use parts. This is especially important for micro- and nanoscale models. For this reason, we are seeing more and more micro 3D printing solutions that meet these needs. One such companies developing this manufacturing method is Germany’s HETEROMERGE. We spoke with its founder and CEO to learn more about its technology and multi-material 3D printing on a microscopic scale.

3DN: Could you introduce yourself and your connection to 3D printing?

Robert Kirchner

I am Robert Kirchner, co-founder and CEO of HETEROMERGE GmbH, based in Dresden, Germany. I have a background in electrical engineering and received my PhD in polymer microsystems fabrication in 2011. During my PhD, and especially afterwards in my professional positions, such as at the Fraunhofer Institute for Photonic Microsystems (IPMS) and the Paul Scherrer Institute, I did intensive research in the fields of nanoimprint lithography, grayscale lithography and 3D printing using 2-photon absorption-based laser writing.

The core of this research has always been the fabrication of very small and functional structures. We have created advanced original structures and exploited polymer replication techniques to be able to enable high volume production. One recent example here is the fabrication of waveguide structures that enable today’s augmented reality glasses. Thanks to the 2-photon 3D printer, in 2013 we were able for the first time to produce extremely small, but at the same time highly precise, 3D free-form structures. What started with the first printing experiments has never left me.

3DN: What is HETEROMERGE, and how did the idea of creating the company come about?

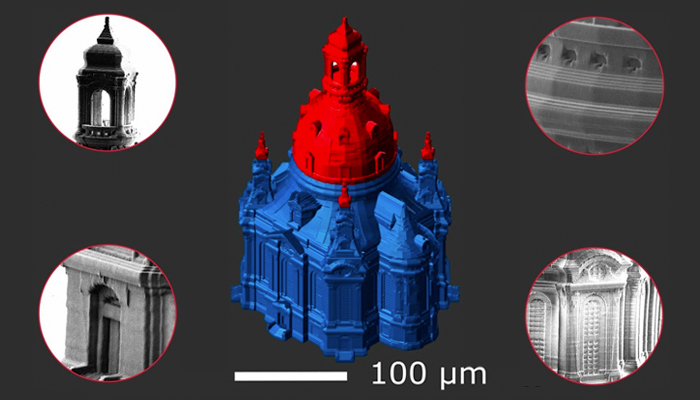

Since my PhD, I have been passionate about functional 3D fabrication and that brought me to turn to fully additive fabrication using our multi-material printhead for 2-photon laser printing as of today. As part of my group’s research at the Technische Universität Dresden, we came to the point of wanting to print multi-material composite microstructures. The reason is simple: different materials have different physical properties. Building structures from multiple materials makes it possible to give them functionality beyond that of a single material.

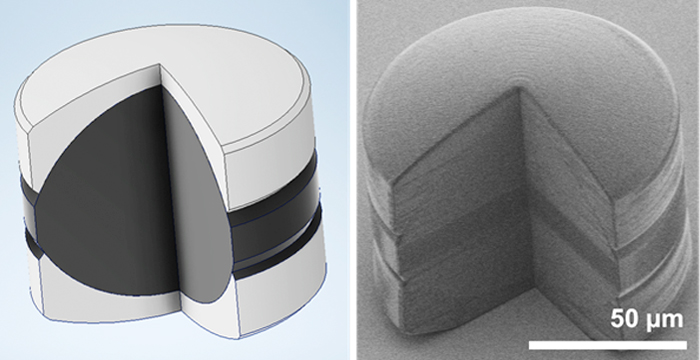

Among many other fields of application, we believe this could be an important contribution to the way we manufacture electronic and optical systems in the future. However, since 2-photon laser printers could only process one material at a time, we faced a realignment problem when changing printing materials. The advantage of high precision 2-photon micro-printing is virtually lost at that point because a suboptimal material exchange routine has to be used. In addition, the material exchange is quite time-consuming if it is not automated. We have developed a solution to this problem: our multi-material printhead. It allows perfect realignment after a fast automated material exchange. We founded HETEROMERGE to commercialize our printhead technology.

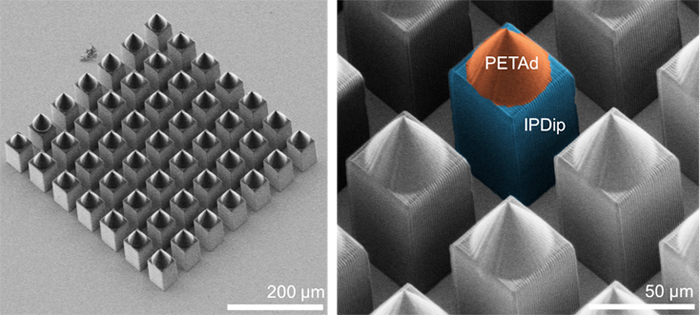

3D printed micro-needles made with the patented technology (photo credits: HETEROMERGE)

3DN: Can you tell us more about multi-material micro 3D printing solutions?

First, our patented printhead technology enables automated on-site material exchange. This completely solves the problem of lateral realignment after material exchange in 2-photon laser printers. With us, there is no more misalignment between regions of different materials. This is crucial for high-quality micro-optics, for example. In addition, with our solution, the exchange process is much faster and more convenient than before. Another big advantage: With our printhead solution, it is possible to print completely independently of the print substrate, i.e., one can print on passive substrates like glass or silicon as well as directly on active components such as LEDs or lasers. This is due to the fact that because we go for an open fluidic solution, our printhead is independent of the substrate and does not impose any limits on the printing surface. We can, in principle, print on module level or even on wafer level to reach a deep integration level for fabrication.

3DN: What are the advantages of this technology? What are the applications?

Anyone printing with a 2-photon laser printer system today, or with next generations of comparable techniques, will be able to implement more functionality into their microstructures in the future with our printhead. In this sense, we are to some extent technology-agnostic. Functional 3D micro-printing, as we call it, will first inspire researchers and developers driving together with us this new technology. Many fields of application are conceivable here.

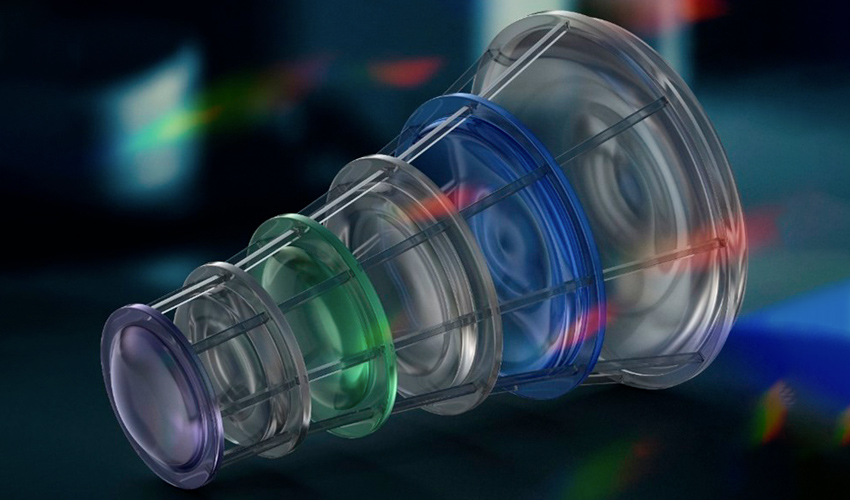

Indeed, Looking at current trends regarding the commercial use of 2-photon laser writing, we see advantages for multi-material structures especially in the fields of micro-optics, photonics, photonics packaging, medical devices and tissue engineering. To give an example:Tiny lens stacks could be printed whose individual lenses are made of different materials. Thus, micro-optics can achieve higher image quality compared to today. We are convinced that our printhead technology will help 2-photon laser writing to find more commercial applications in the above-mentioned areas, but also beyond.

We developed the printhead technology in the printhead technology on our Photonic Professional GT2 system from Nanoscribe and optimized our add-on for it. In the future, we can also further develop the add-on so that it can be used for other commercial printing systems and for self-built 2-photon lithography systems.

Photo Credits: HETEROMERGE

3DN: Where do you see additive manufacturing in the next 10 years? What about HETEROMERGE?

In general, 3D printing has already become firmly established in many areas within the industrial production of larger structures. 2-photon laser printing as solution for micro additive fabrication is reaching the same maturity. We see this to become a valuable contribution to what is called in electronics fabrication low volume and high mix applications where 3D printing can provide very flexible production.

In the case of HETEROMERGE or functional microstructures in general, we can see additive manufacturing being used first in the field of high-quality micro-optical elements and components. We hope to see a minimal invasive medical imaging system being realized with additively fabricated micro-optics. We want to enable AR glasses that can no longer be distinguished from normal glasses due to powerful and small optical components. Furthermore, we want to help information to be processed in data centers more efficiently by optical fibers being coupled into chips without loss via printed functional micro-optics. We may also see the first optical chips, where we will contribute functional structures. However, we are also convinced that we cannot even imagine many applications today. New markets will emerge when the possibilities of functional 3D micro-printing are recognized. We are only at the beginning of our journey.

3DN: Any last words for our readers?

First of all, I would like to thank you for allowing me to briefly introduce HETEROMERGE! We would be happy if we could use this to reach your readers who work with 2-photon laser writing systems and who would like to print structures with multiple materials. In any case, anyone who does not have their own printing system but has a possible application for functional 3D microstructures is welcome to contact us. We’re always looking for applications to challenge our technology. You can find more information about the company HERE.

Multi-material micro-lens stack (photo credits: HETEROMERGE)

What do you think of the micro 3D printing solution from HETEROMERGE? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: HETEROMERGE

micro 3D printing solution from HETEROMERGE is extremely useful, it has helped me work much more accurately and quickly