#3DStartup: 3D Spark Helps Companies Cut Costs and Waste in Production

The adoption of additive manufacturing in companies is steadily increasing. More and more companies are interested in taking advantage of 3D printing, but there is often uncertainty about choosing the right technology, materials and software. Spark 3D, a startup based in Hamburg, Germany, has developed a software solution that helps companies find ways to cut costs, shorten delivery times and reduce CO2 emissions in production. In addition, 3D Spark’s platform ensures that companies can benefit from an automated assessment of their 3D printed parts to identify an optimal product development process. We spoke with co-founder and co-CEO Ruben Meuth to learn more about 3D Spark’s work.

3DN: Could you introduce yourself and your connection to 3D printing?

I’ve always been fascinated by how things are made. For example, when a milling head goes through metal like butter or sparks fly during spot welding in a fully automated car body production line, and the end result is a product that people love, that’s great. 3D printing as the “supreme discipline of manufacturing” was then the logical consequence for me. As early as my master’s thesis, I developed an initial software prototype to automatically select the most suitable 3D printing process based on component requirements. Later, as Head of Business Development at the renowned Fraunhofer Institute for Additive Production Technologies (IAPT), I frequently heard sentences in many discussions with industry such as: “We are convinced about 3D printing, but we don’t know where to start. We don’t have the capacity to compare various processes and materials with each other per use case and to benchmark them for manufacturability and especially costs. As a result, we are losing out on major cost-saving potential.”

The 3D Spark team: Dr.-Ing. Fritz Lange, Dr.-Ing. Arnd Struve, M.Sc. Ruben Meuth (Left to Right)

We wanted to solve this problem, and this only became possible thanks to the expertise of Dr.-Ing. Arnd Struve and Dr.-Ing. Fritz Lange, who were simultaneously working on their doctorates at the IAPT in the field of software development for lightweight construction, design automation and heat sinks for 3D printing. We then developed precursors of our current software for large industrial customers. When the feedback was: “That’s brilliant, we want to industrialize that,” we said: “Let’s do it!” and spun off with 3D Spark.

3DN: How did 3D Spark come about and what is your mission?

We dream of production without waste. Billions of parts are produced every day – many of them with higher costs, delivery times and CO2 emissions than necessary. Manufacturing companies often simply lack the necessary transparency to select the cheapest, fastest and most sustainable manufacturing process per component. The 3D Spark platform provides this transparency, currently specializing in industrial 3D printing, while other manufacturing processes are constantly being added. This enables smarter decisions in the selection of manufacturing processes and leads to more efficient, sustainable and crisis-resistant production.

3DN: What is your part screening software? What are the benefits?

OEMs are using 3D Spark to reduce production costs and delivery times while increasing supply chain reliability and component performance. Alstom, for example, a global leader in smart and sustainable mobility solutions, has already achieved savings of more than €1.8 million (2022) and €5 million (2023 planned) using 3D Spark.

Data security is increased as the buyer has to send fewer quote requests with sensitive CADs and drawings to fewer service providers, measurable learning effects for employees through 24/7 available software to track their requests and a dashboard with current costs, delivery time and CO2 savings on company / group level helps to generate management support and funding.

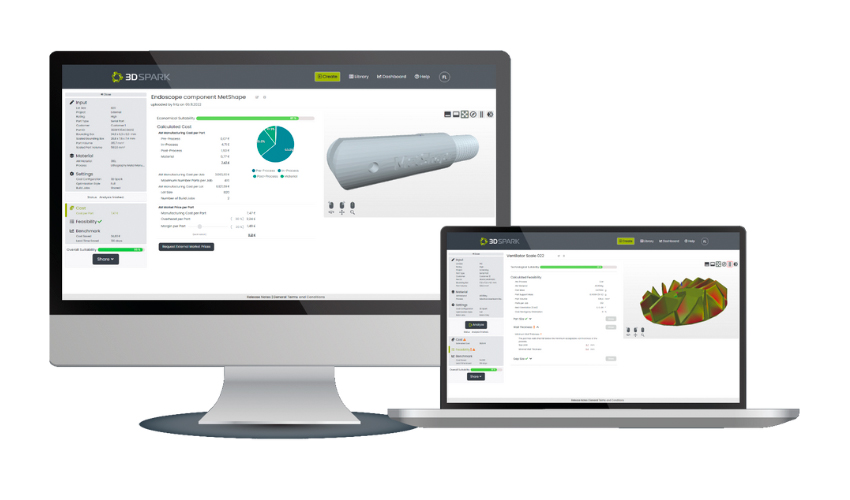

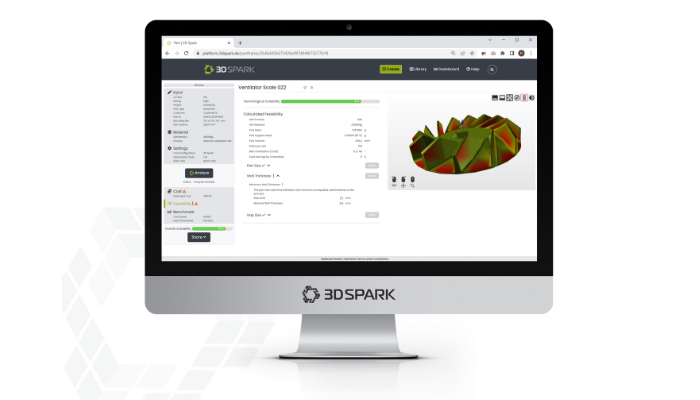

3D Sparks software helps companies save costs, among other things

Manufacturing service providers like MetShape and Fabitive analyze manufacturability for 12 printing processes and calculate production costs in seconds, speeding up quoting by 90%. Sales reps have more time to generate revenue, technology experts can focus on value-added activities such as design work for commissioned projects, inappropriate queries are answered 100% automatically, eliminating the burden on staff, and fewer individual software tools are needed, saving licenses and avoiding media disruption.

As input, the software processes CADs, drawings and metadata such as number of pieces, material, etc. For each process-material combination, the software performs a manufacturability analysis, orientation optimization, nesting, support generation, pre- and post-process costing, break-even calculation with casting and milling and much more.

3DN: In your opinion, what is the added value of 3D Spark’s software for additive manufacturing?

Our solution is a tremendous enabler for AM as an industry, quantifying the potential cost savings and significantly lowering the barrier to entry by automating the analyses. Importantly, however, our solution is open to technology: the software bench markets AM against an increasing number of manufacturing processes such as casting, injection molding and milling – and often processes other than AM, are more appropriate. This is wonderful – our goal is to provide a transparent, independent basis for decision-making when selecting manufacturing processes.

3DN: Could you tell us something about future projects?

We are very pleased to be able to support Miniatur Wunderland, Germany’s No. 1 tourist attraction, with our software in setting up a 3D printing department. The passion that is put into the production of the thousands of unique pieces and the world that is and has been created is simply inspiring. AM is of course predestined for this.

3DN: Any last words for our readers?

Feel free to get in touch with further questions and ideas for collaboration. For more information, visit the 3D Spark website HERE.

What do you think of 3D Spark? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: 3D Spark