#3DStartup: 3DNextech on their professional and automatic surface finishing machine

3DNextech is an Italian company specialised in the development of products and technologies related to the world of additive manufacturing, digital manufacturing and 3D printing. Their 3DFinisher machine was developed for other companies to use, it is a solution that can be scaled up if needed. For example, it could easily be engineered for bigger industrial contexts. The 3DFinisher is essentially the first professional automatic device for the surface finishing of ABS, ASA and cellulose acetate. Its development came after the realisation that sometimes 3D printed parts need to be waterproof or present strong mechanical properties, which is far from always being the case. This device meets exactly these needs in the industry. How does it work? What are the benefits? Who is adopting the solution? We spoke to Andrea Arienti, CEO and Founder of 3DNextech to give you some answers!

3DN: Can you present yourself and tell us how you founded 3DNextech?

My work experience starts in 2008, within the laboratories of The BioRobotics Institute of the Sant’Anna School of Advanced Studies. Joining this institute to develop my thesis at first, I ended up working there for seven years, involved in the mechanical design of the marine robots that were developed inside the lab for research purposes. I have started dealing with 3D printing since additive manufacturing technologies (and ABS FFF in particular) were often the only viable option for realizing our non-conventional soft robots.

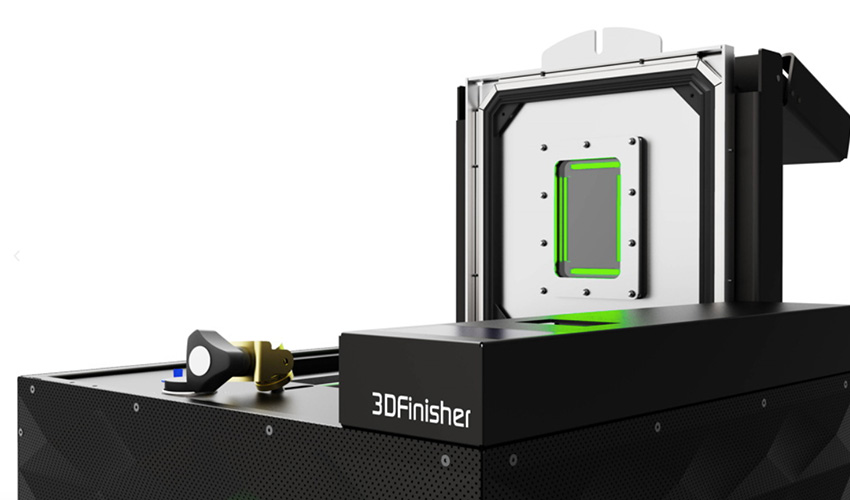

In 2015, I founded 3DNextech, a Spin-Off of the Sant’Anna School of Advanced Studies of Pisa, specialized in the development of products and technologies related to the world of digital manufacturing, additive manufacturing and 3D printing. Offering a 300 x 300 x 300 mm workspace, our first B2B machine (3DFinisher) was designed with SMEs in mind, but the technology at its core is scalable, and could be engineered for bigger industrial contexts resulting in turnkey projects. 3DNextech also supports their customers in designing and/or optimizing their additive manufacturing workflows, in such a way to enable new applications, increase quality, and support their business model. In parallel, 3DNextech keeps investing heavily in R&D, in such a way to extend the application scenarios of our 3DFinisher and bring other innovative additive manufacturing and post-processing technologies to the market in the near future.

CEO and Founder, Andrea Arienti

3DN: How did the idea of creating 3DFinisher come up?

When I worked as a researcher, I intensively used Additive Manufacturing technologies (ABS FFF in particular) to create the mechanical components of our robots. The Additive Manufacturing technologies for this purpose are fantastic, they have however some important shortcomings, that were particularly evident in our applications: 3D printed parts were not waterproof and their mechanical performances were far from being sufficient, and their rough surface favored the proliferation of algae on our robots. In order to solve these limitations, I built the first 3DFinisher prototype, that I have used with success in many robotics applications for several months at the time.

After filing our first patent on this technology, in 2015 my partners and I decided to start a company that would develop technologies able to help the transition from “mass production” to “mass customization”. While my first contact with 3D printing dates back to 2008, it is in 2015, with 3DNextech, that we really started pushing additive manufacturing technologies, trying to make them automatic, repeatable, easier to use, and production-ready.

The 3DFinisher

3DN: Can you explain to us in detail how to use the 3DFinisher? Who is it meant for?

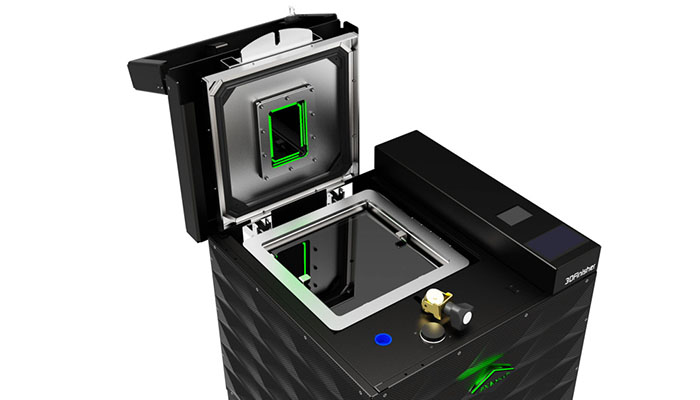

Our patented technology is based on a chemical-physical process which takes place in very specific atmospheric conditions: the 3DFinisher finely controls all parameters inside the sealed chamber in such a way to guarantee a perfect and repeatable enhancement of all parts. The device is very easy and safe to use. The operator never needs to touch the chemical agents, which are sold in thermosealed disposable cartridges. These chemicals are always confined within the machine, and waste products are automatically ejected as well at the end of the process. The device is plug & play, and does not need any additional infrastructure (e.g. no fume hood is needed). It can be operated via the on-board display or remotely (through smartphone, tablet or PC) as it offers WiFi and Ethernet connectivity.

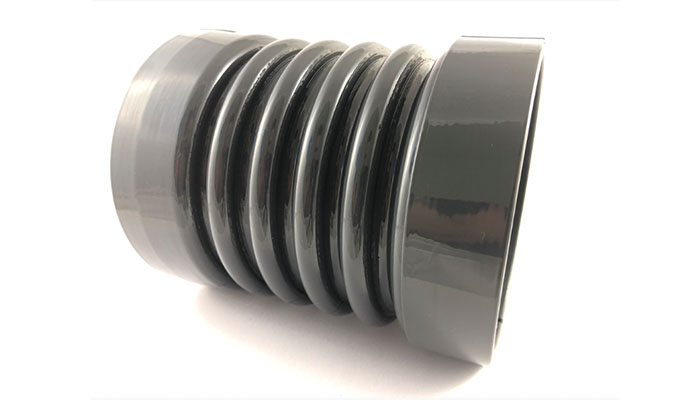

Raw parts are placed inside the device, and undergo an automatic process which makes them stronger, glossy, waterproof, dirt resistant, washable and sterilizable. Completely interconnected and fully compliant with the Industry 4.0 principles, the machine can be controlled and monitored remotely. One finishing process lasts 60 minutes on average: it can smooth several objects at the same time, and makes use of disposable cartridges containing our proprietary solvent, which are sold separately. The workflow goes as follows:

- Preparation

The operator places the raw objects inside the sealed work chamber, sets the process parameters and places a disposable cartridge containing our proprietary solvent inside the 3DFinisher.

- Process

Parts undergo a chemical-physical process which takes place in controlled atmosphere (pressure, temperature).

- Results

After the process all parts achieve a perfect, uniform surface finishing, becoming waterproof, paintable, smooth and glossy. Mechanical properties are considerably improved as well.

3DN: How important is nowadays the finish of the parts for FFF technology?

To date no 3D printer can guarantee a perfect surface finishing of printed parts. Raw 3D printed parts can only be considered semi-finished products, that require a considerable amount of additional work in order to improve the aesthetics of the surface as well as the mechanical properties of the parts (e.g. manual sanding, application of resins, primer, etc). These manual treatments entail considerable costs for companies and only partially solve the problem: the final quality is often not satisfactory, and even when it is, repeatability is not guaranteed by any means. In many contexts, these shortcomings hinder the widespread adoption of 3D printing for production purposes. 3DFinisher was designed precisely to solve all of these issues.

3DN: In your opinion, how will FFF technology evolve in the coming years?

I believe that the FFF technology has very important peculiarities and that it has a much brighter future than can be thought if a superficial analysis is made. This technology is the only one that allows (by pausing the printing process) to incorporate components made of different materials (other polymers, metals, etc…) and above all with different technologies (CNC milling CNC turning, etc…) in this way it is possible to create very complex objects with unique mechanical and functional characteristics. It is also possible to incorporate electronic components, sensors, etc… into the object produced by FFF. In addition, industrial grade FFF printers are certainly the most robust and reliable in many industrial environments. Do we want to talk about the materials that can be printed? There are no other technologies that can compete on this point. The FFF technology is now very consolidated and the results are very repeatable. In the future of this technology I see the shift towards direct and indirect production of increasingly complex products.

3DN: Do you have any last words for our readers?

People traditionally think of manufacturing as a rather self-contained process: we are trying to promote a considerably broader view of this field. Additive manufacturing technologies can in fact greatly influence processes such as logistics, and can even redefine and/or enable the company business models. The influence these technologies can have on the conventional design process is also very evident. In order to exploit the full potential of these new technologies, traditional mechanical design workflows should be revised and updated in light of the new possibilities that these offer, and the constraints and assumptions they are overturning (such as the fact that a functional object should be composed by a number of homogeneous subparts – in terms of physical and chemical characteristics, or the morphological constraints arising from conventional production methods based on material deformation or subtraction, no longer holding).

This revolution is taking place not without difficulties and misunderstandings. By comparing these new technologies to conventional ones in specific contexts where the latter have proven to work just fine, some critics argue that there is no true benefit in adopting additive manufacturing technologies at all.

At the other side of the spectrum, some describe these technologies as miraculous solution to all problems, which should completely replace all previous manufacturing schemes and work their magic with no need for the user to get involved in the process. Both these lines of argumentations are of course not completely true in our opinion. The additive approach has the potential to truly disrupt the manufacturing world, but as every other new technology it needs to be comprehended, optimized, tailored to the specific needs of the client, compared to alternative solutions case by case.

There will be cases where traditional technologies will still be the best choice, others where an application could only be realized by adopting more innovative paradigms and materials, and still others where a combination of older and newer production schemes might be the best bet. Trying to replicate objects of the past with additive technologies is often a mistake and a missed opportunity. What 3DNextech is trying to do is to design and leverage innovative additive manufacturing technologies to design the objects of the future: we stand beside companies which want to become first-movers in this sense, doing our best to support their transformation.

Find more information HERE.

What did you think of our startup of the month? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!